You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nick Dunhill's 7mm W (A6) or Whitby Tank Workbench

- Thread starter Nick Dunhill

- Start date

Nick Dunhill

Western Thunderer

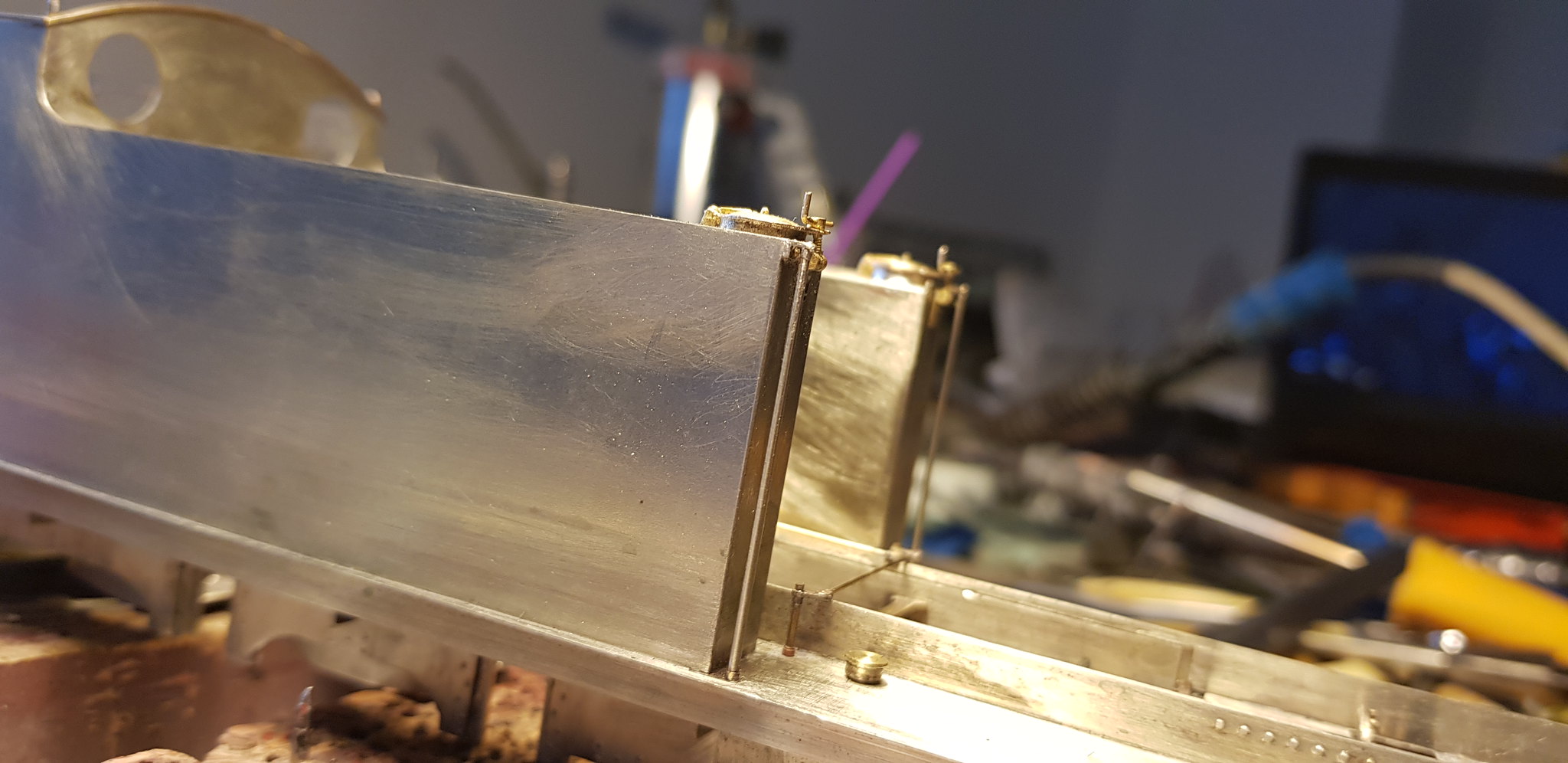

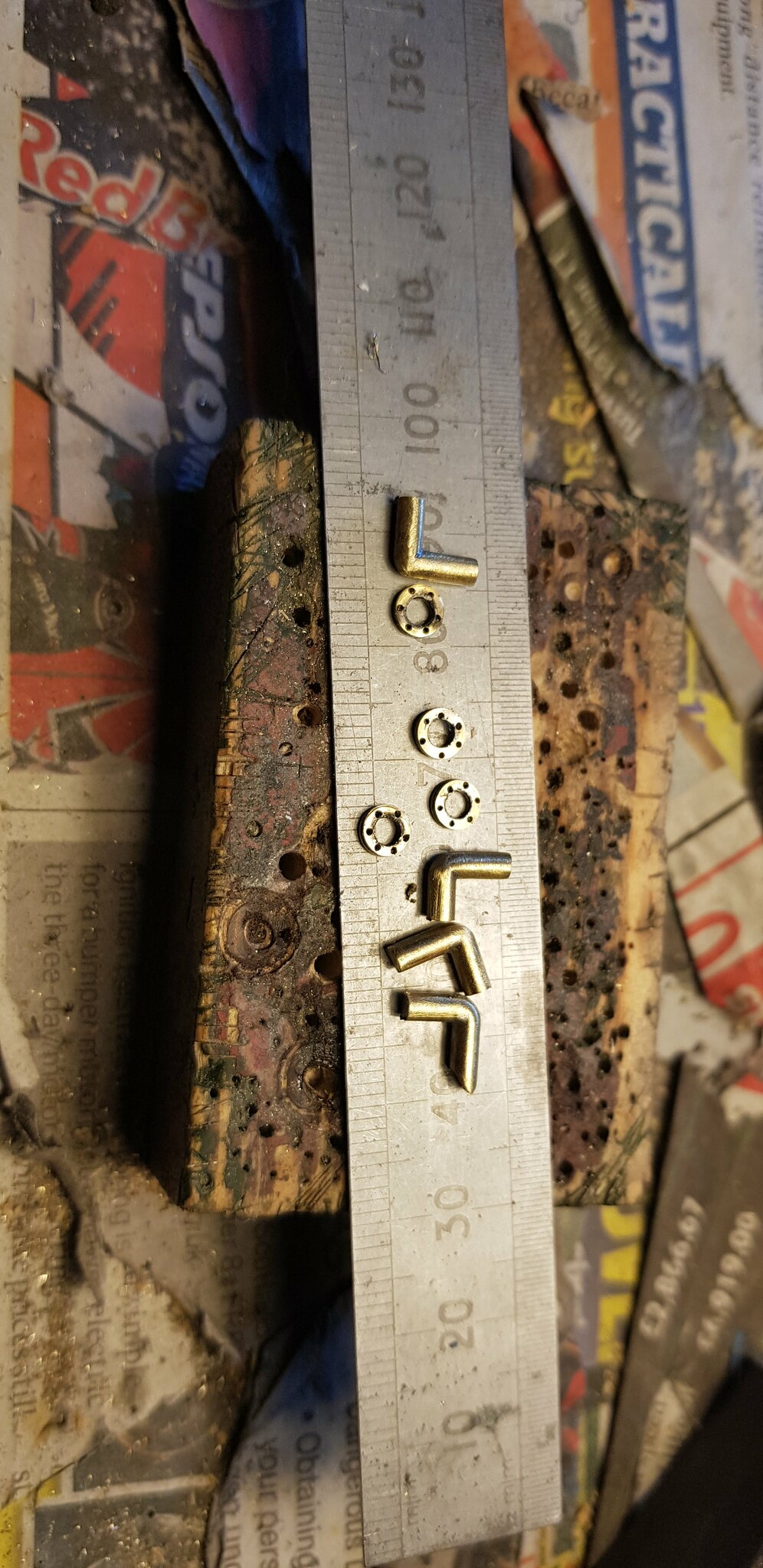

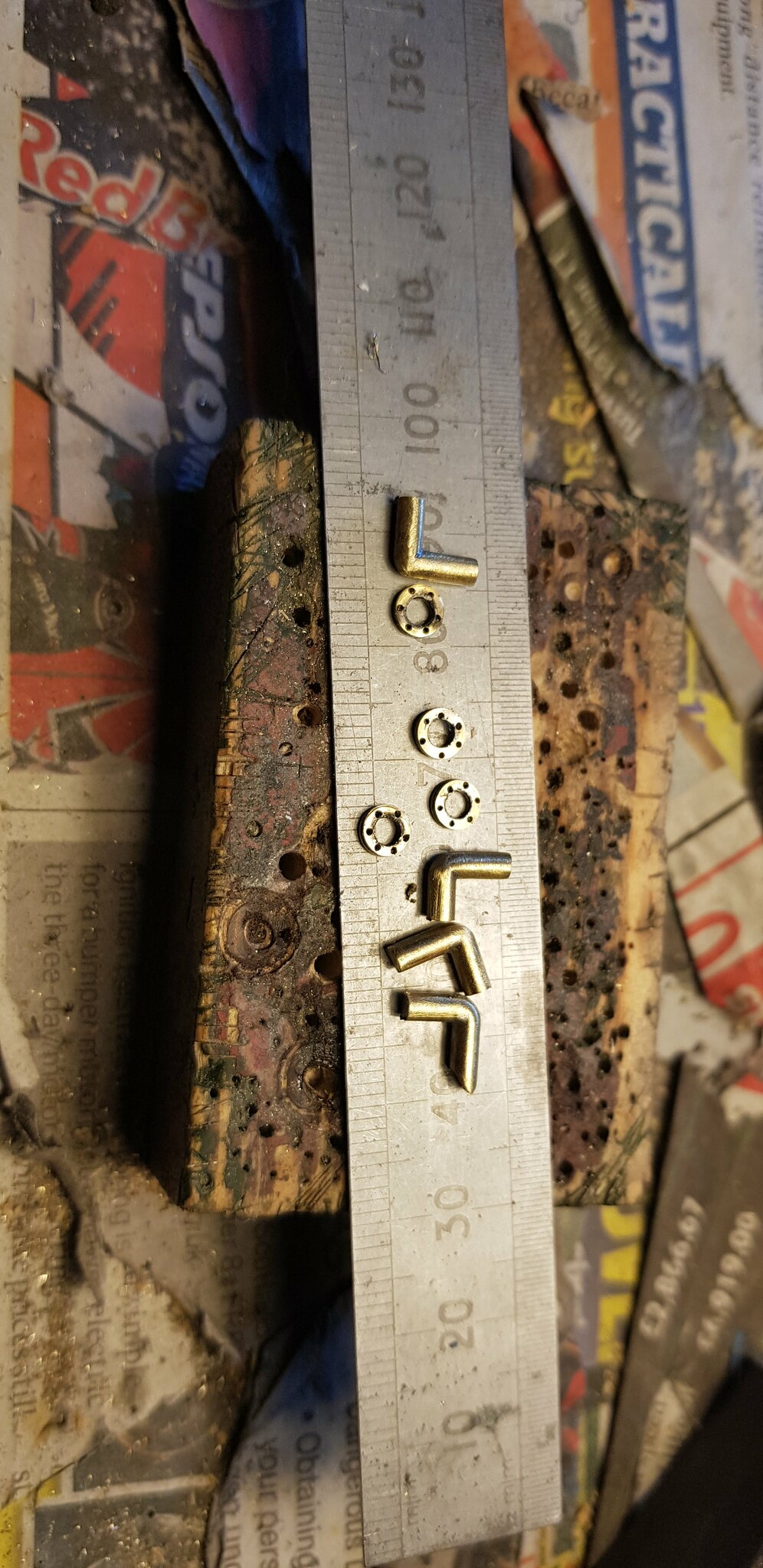

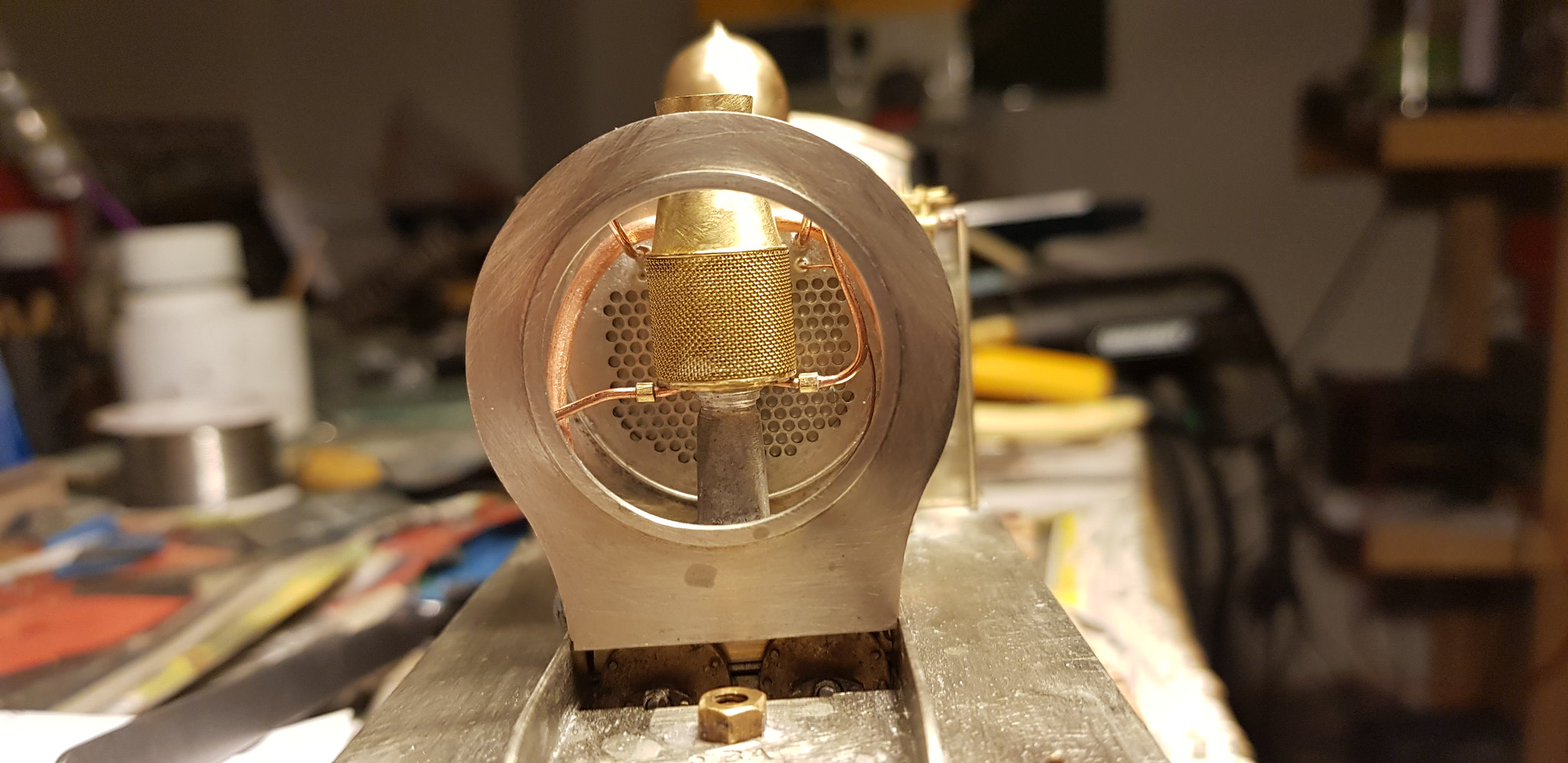

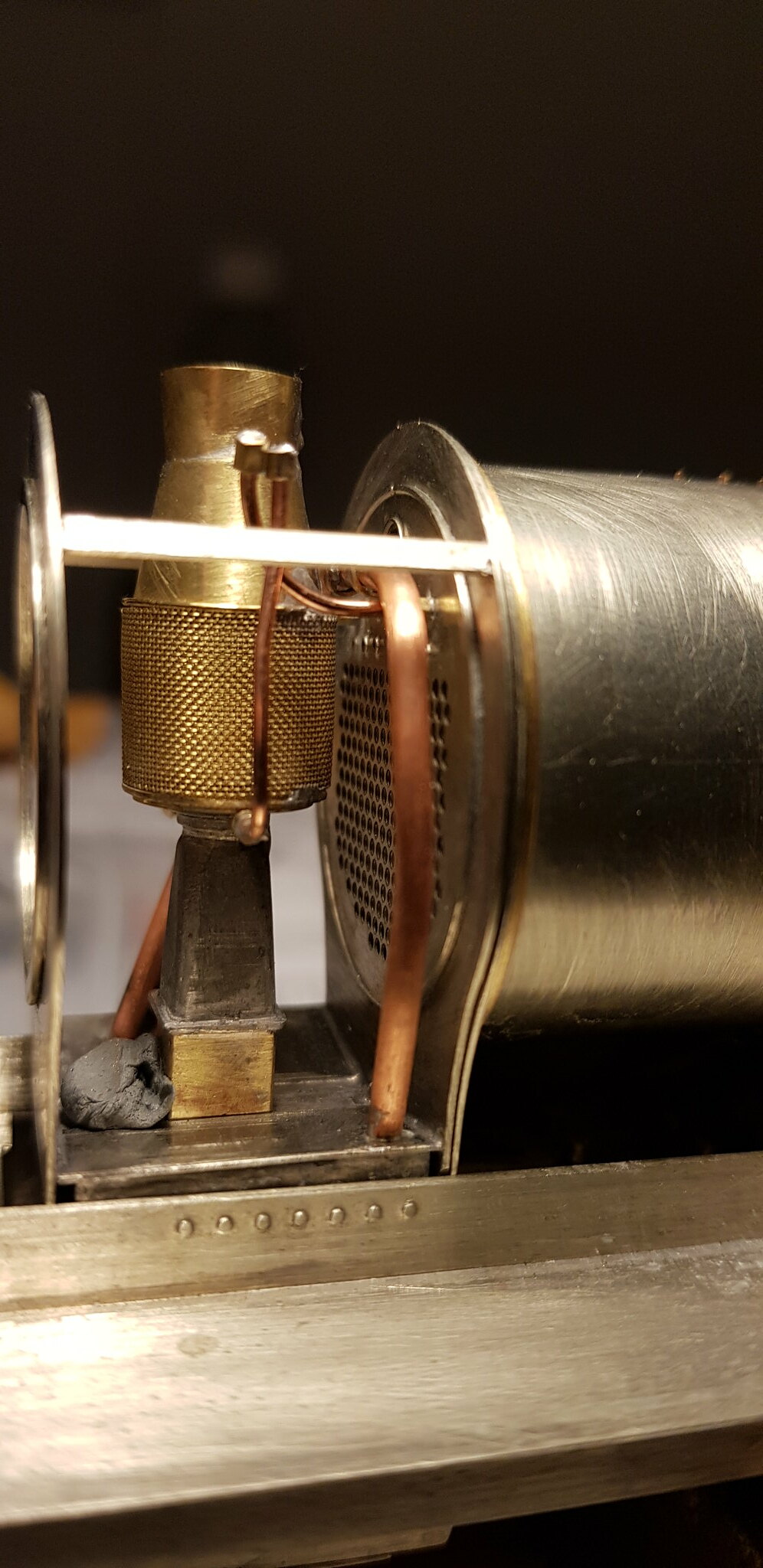

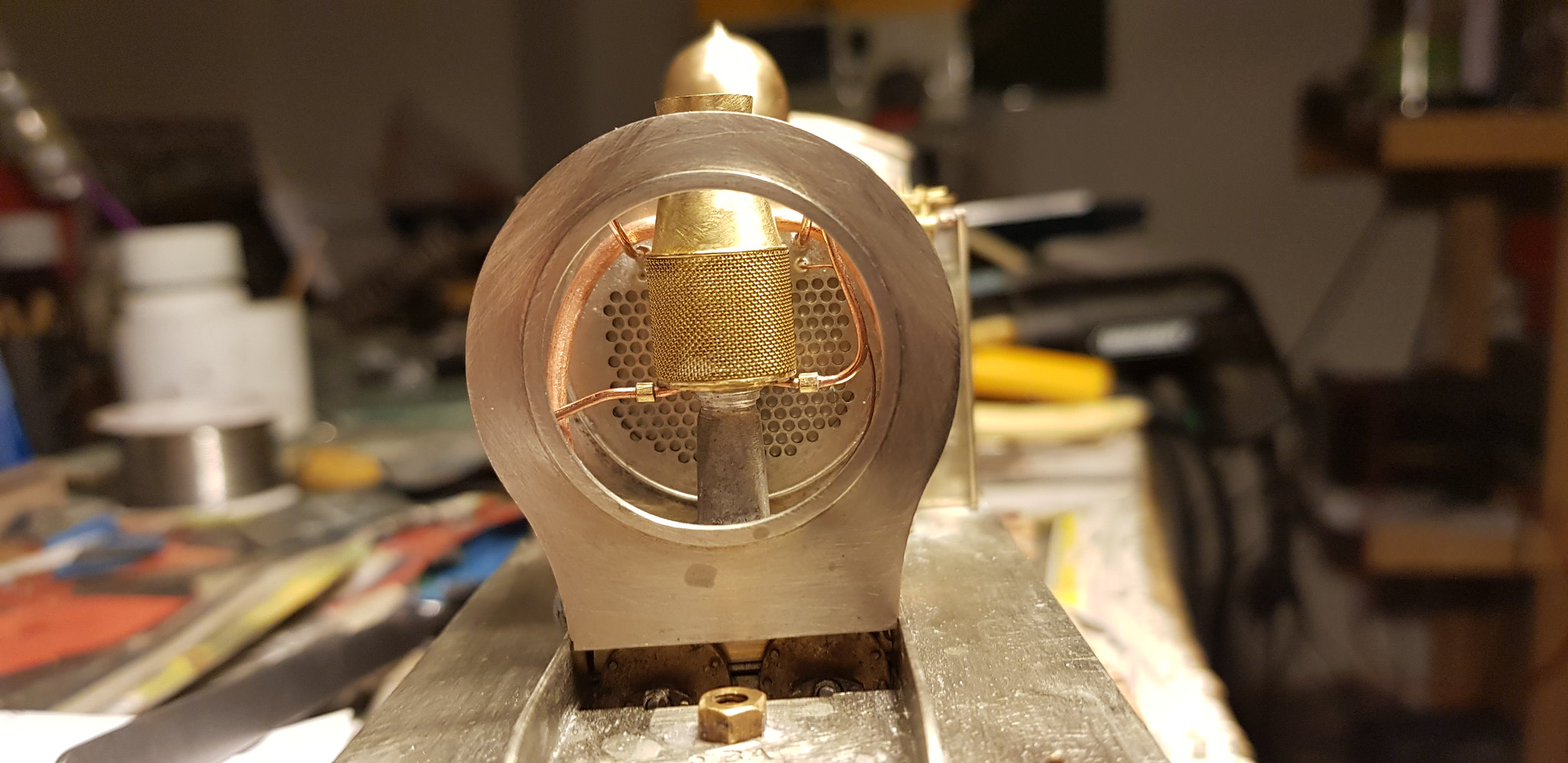

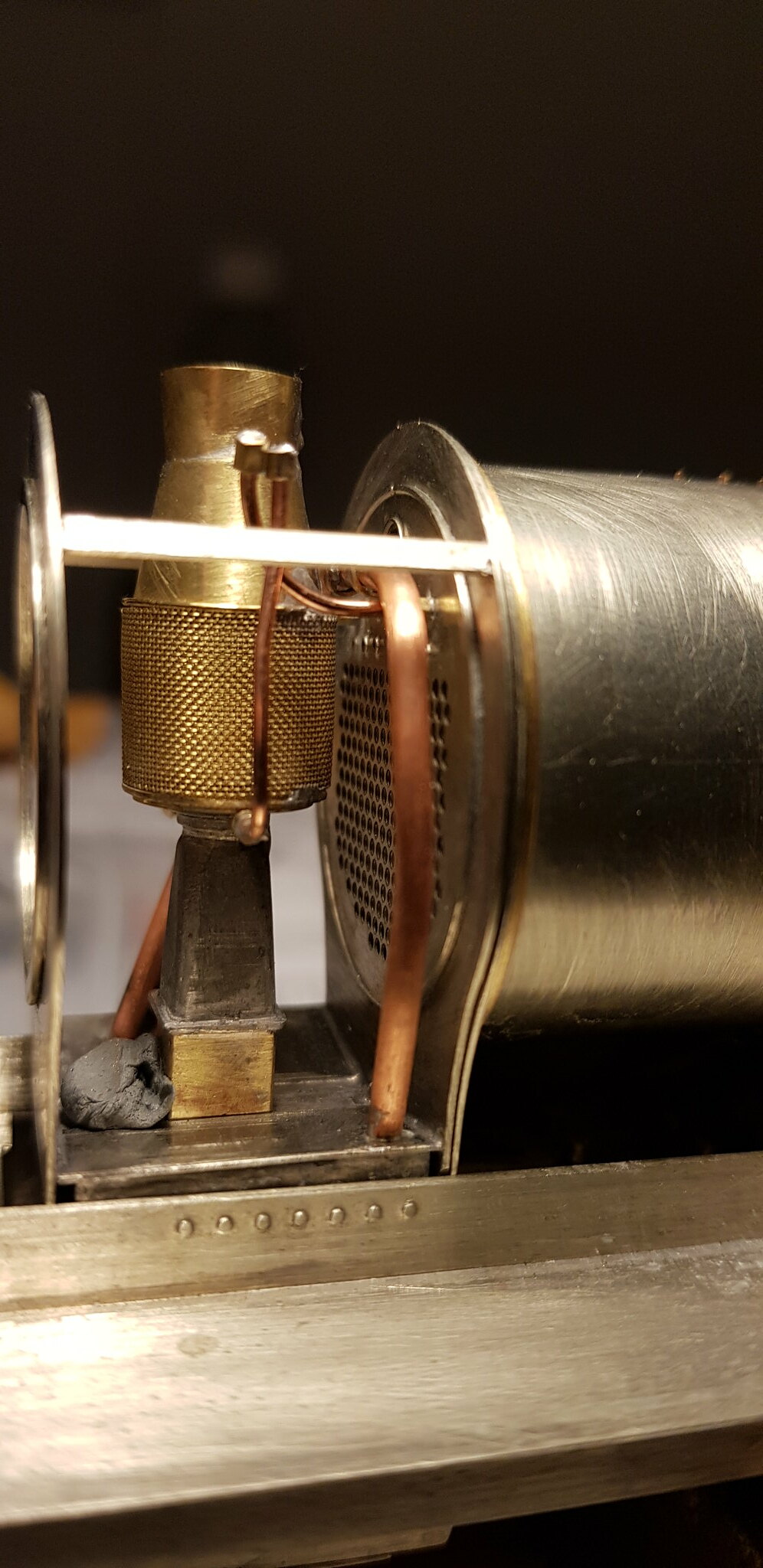

....bits of smokebox detail. I took measurements from my Flickr account here;

nick dunhill’s albums | Flickr

and bashed them into the calculator here;

Flat Cone Template Calculator

and cut out paper templates to make the petticoat pipes. They're cut from thin brass, and formed round a small drill shank. I got lucky and found some driving wheel spacers that were the perfect size for the bottom of the mesh cylinders, cut to represent the spark arrestors. I cut out some door locking crossbeams and added a representation of the steam pipes.

I'll finish off when the blast pipe castings turn up from Laurie Griffin!.....

nick dunhill’s albums | Flickr

and bashed them into the calculator here;

Flat Cone Template Calculator

and cut out paper templates to make the petticoat pipes. They're cut from thin brass, and formed round a small drill shank. I got lucky and found some driving wheel spacers that were the perfect size for the bottom of the mesh cylinders, cut to represent the spark arrestors. I cut out some door locking crossbeams and added a representation of the steam pipes.

I'll finish off when the blast pipe castings turn up from Laurie Griffin!.....

Nick Dunhill

Western Thunderer

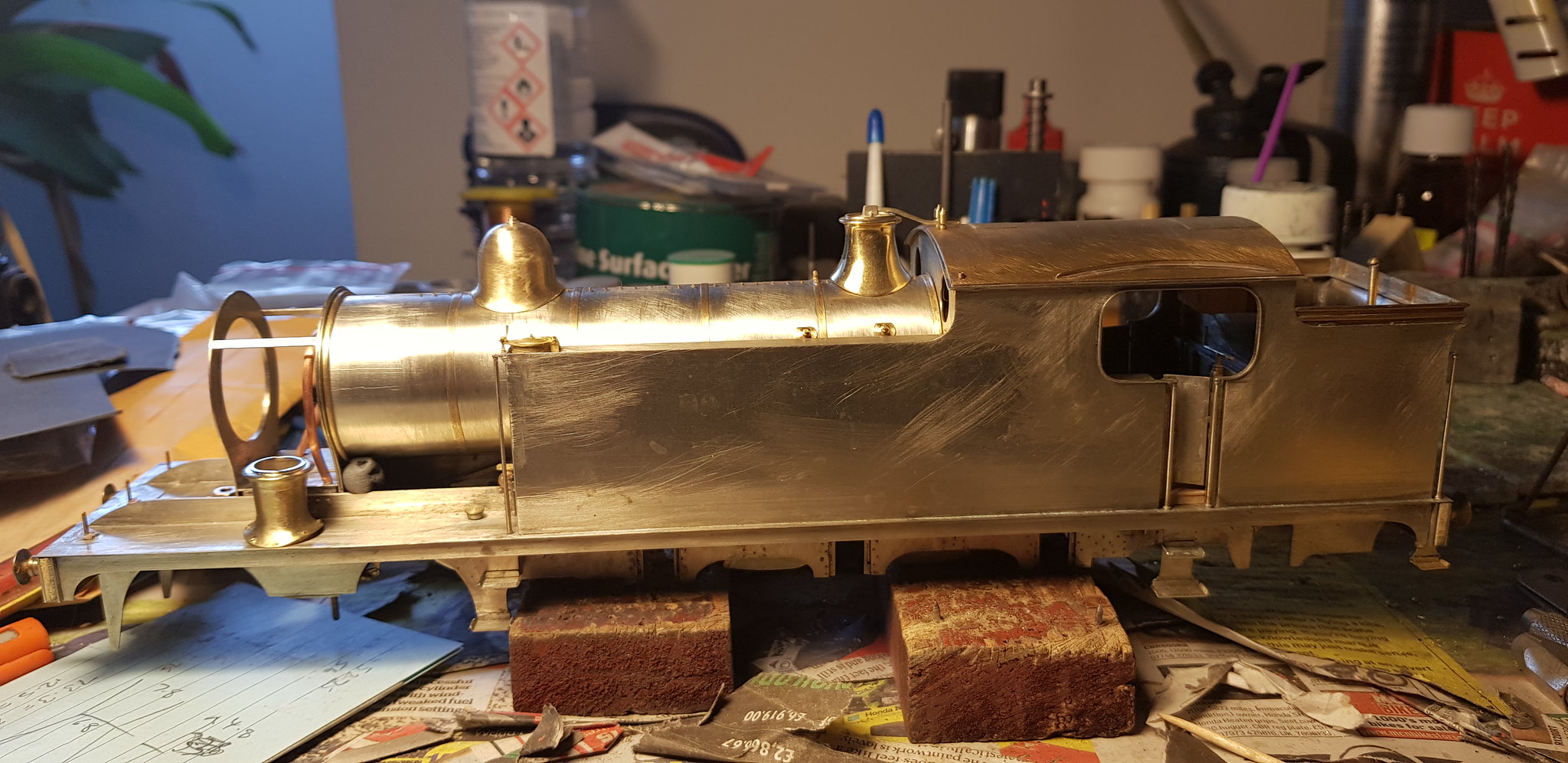

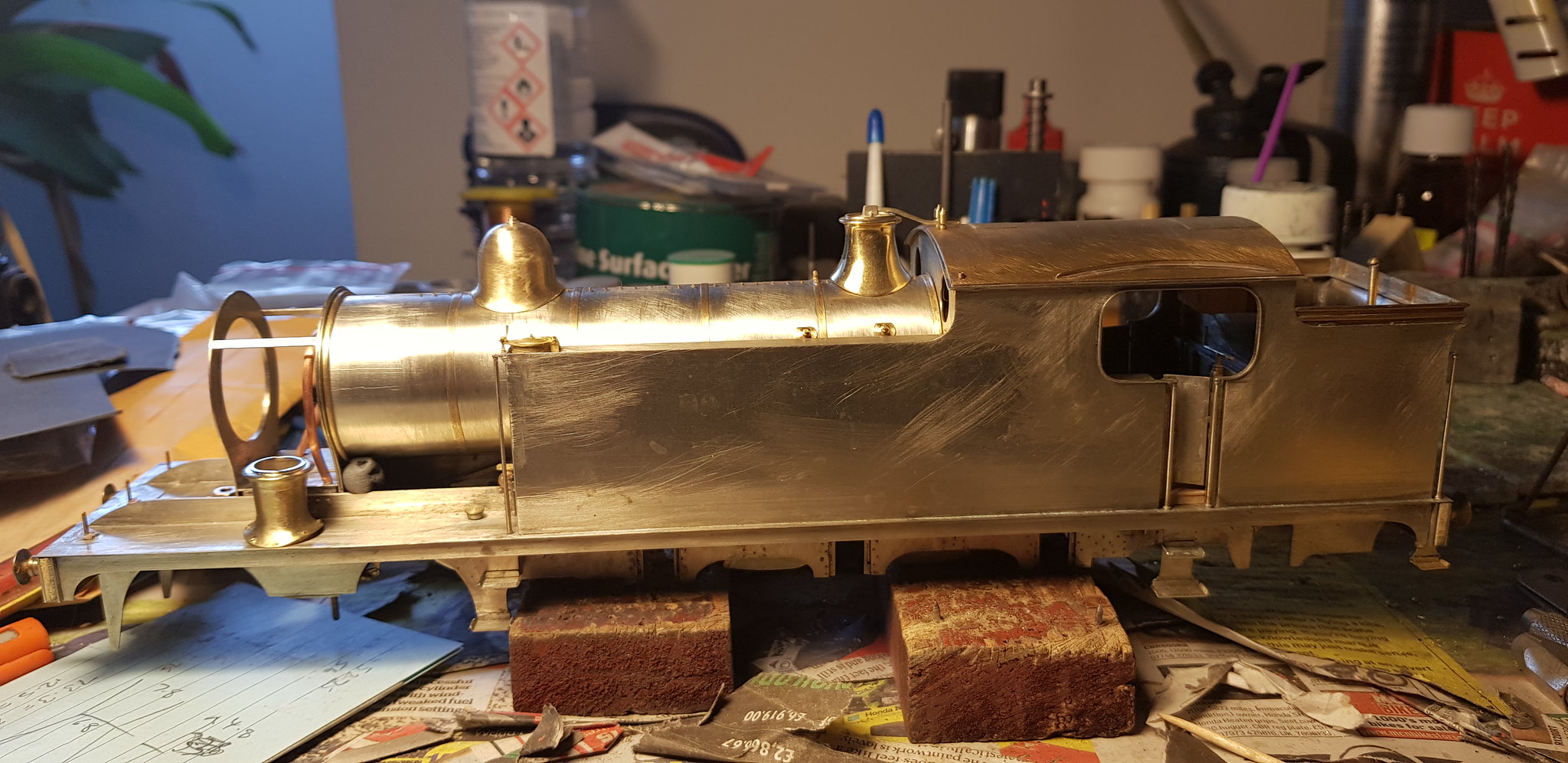

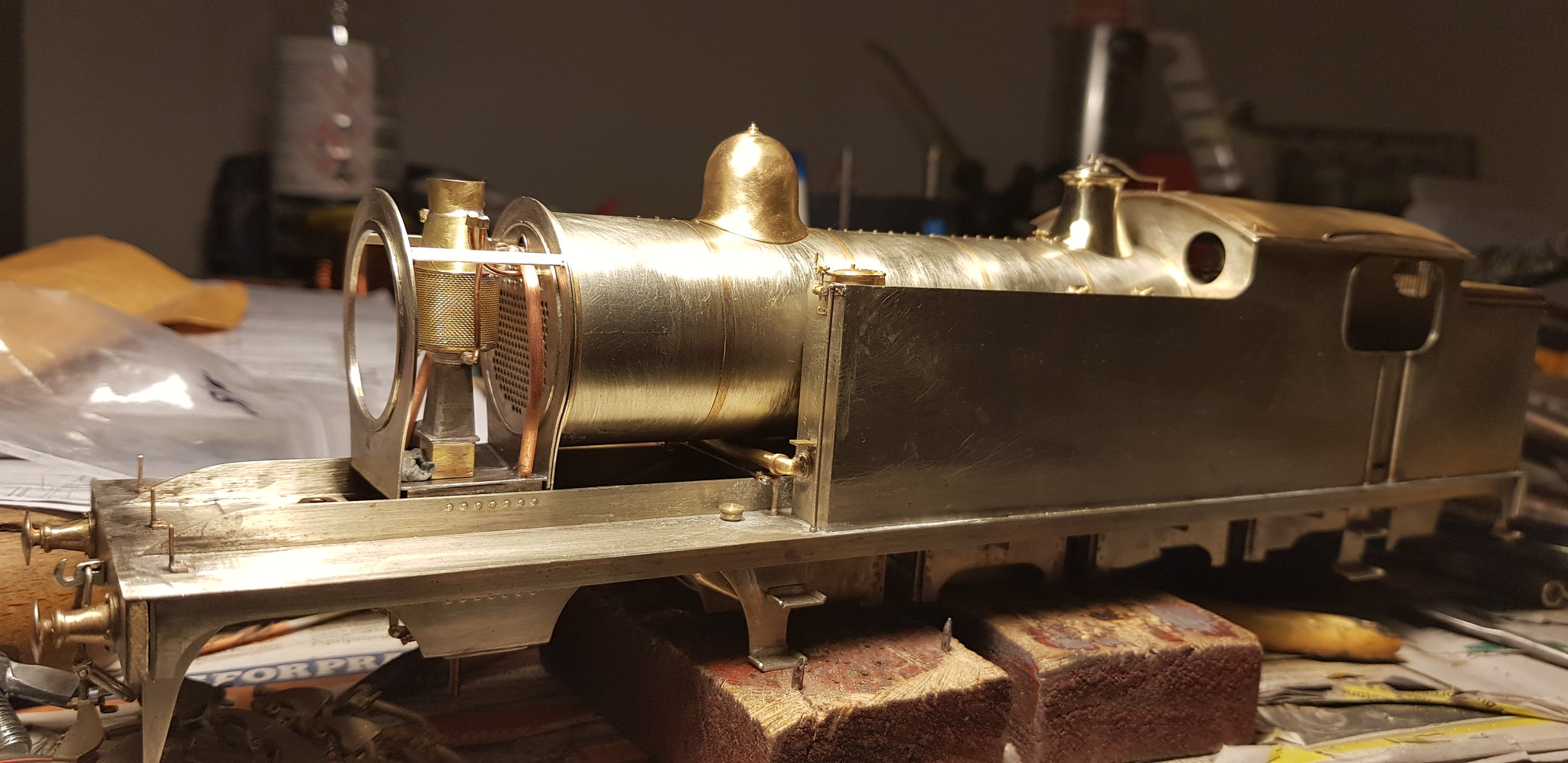

......so this post is a bit of a catch up. I've been waiting for odds and sods to turn up, so have been moving on to other things without finishing what I was doing and it was all starting to get a bit disjointed. I fettled boiler fittings, chimney, dome and safety valves and then my etchings arrived, yay.

[

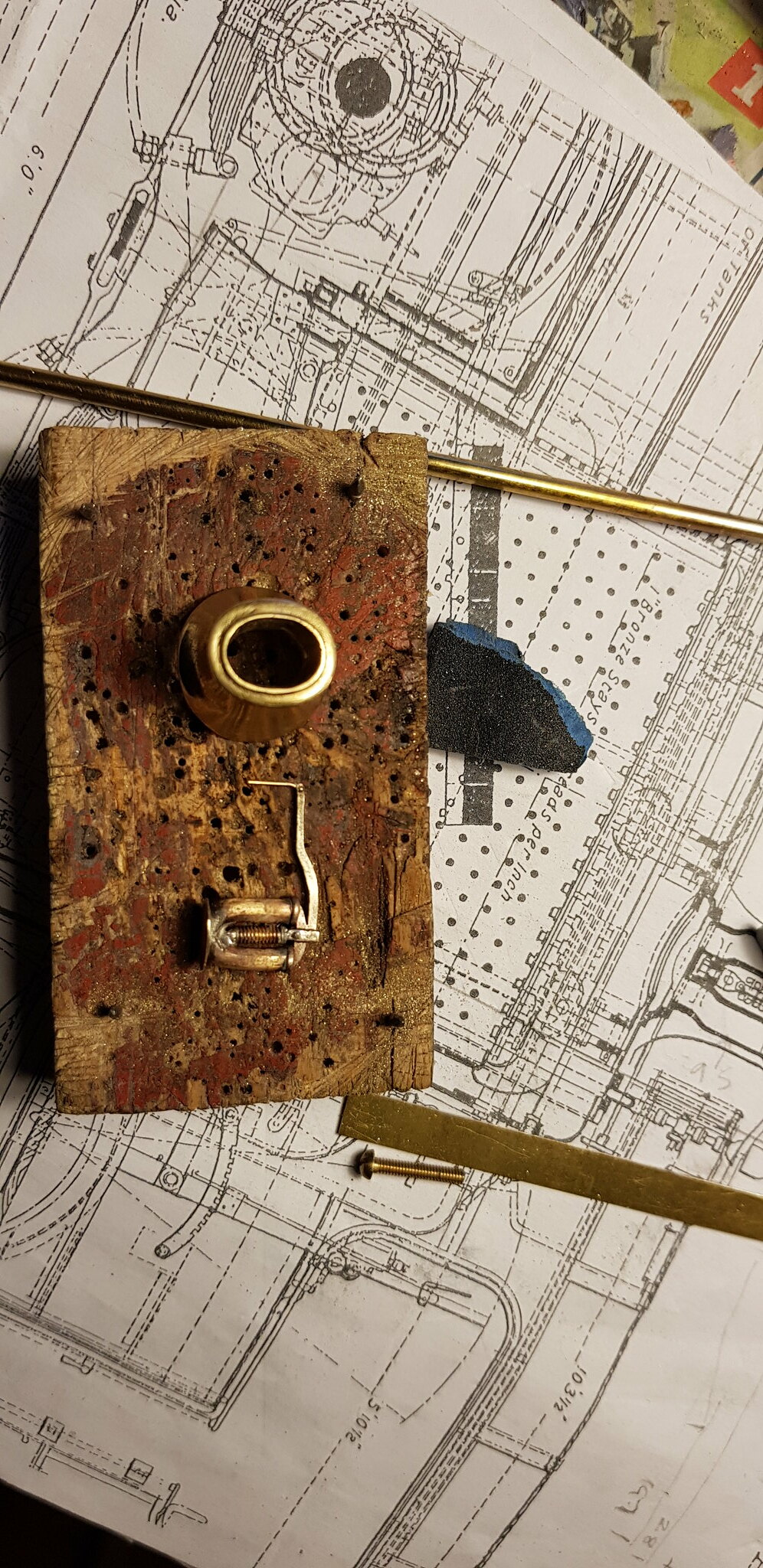

These mud hole covers were a bit vexing to fit. They required spinning in a mini drill to clean up, and then were awkward to position.

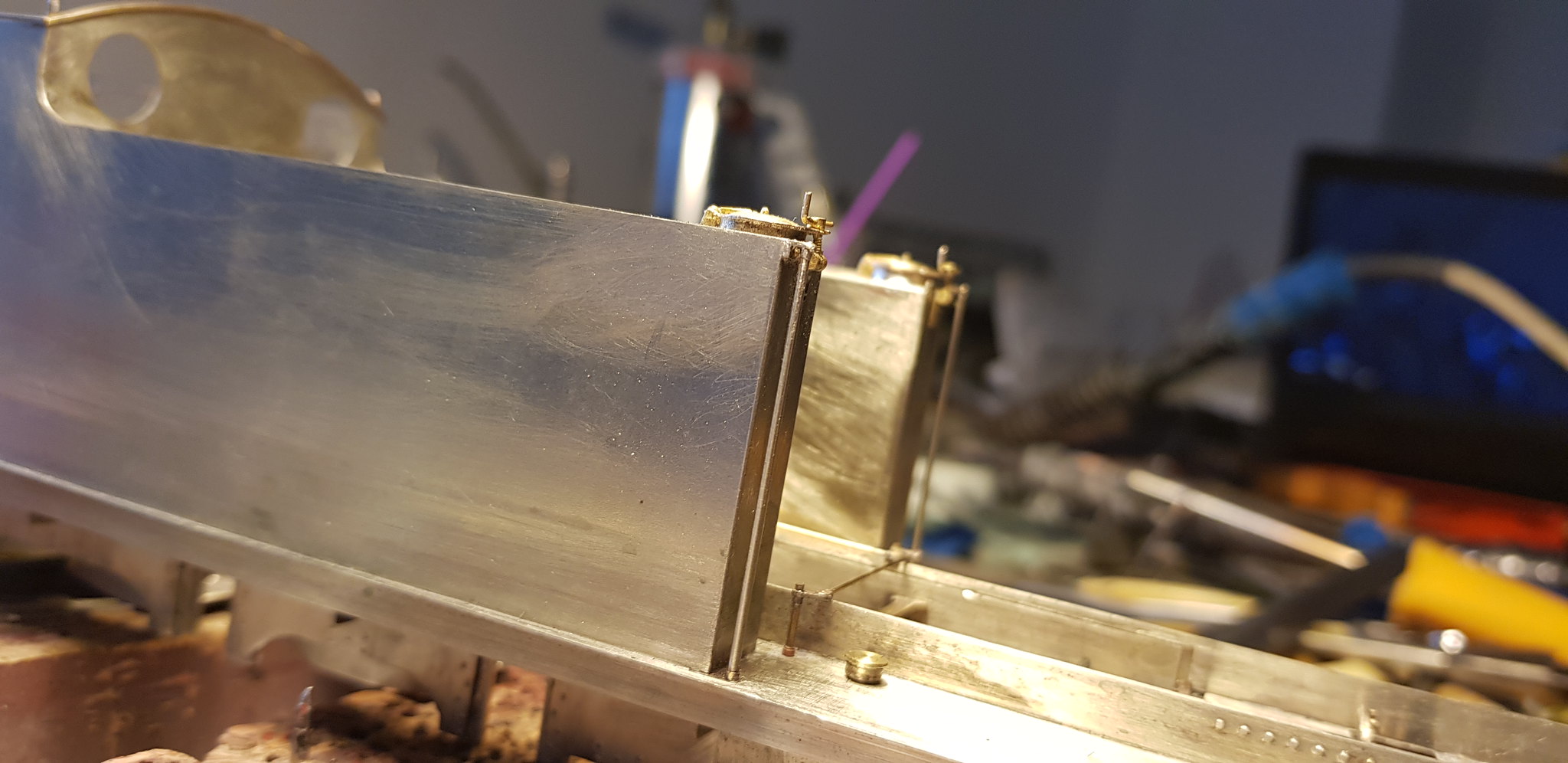

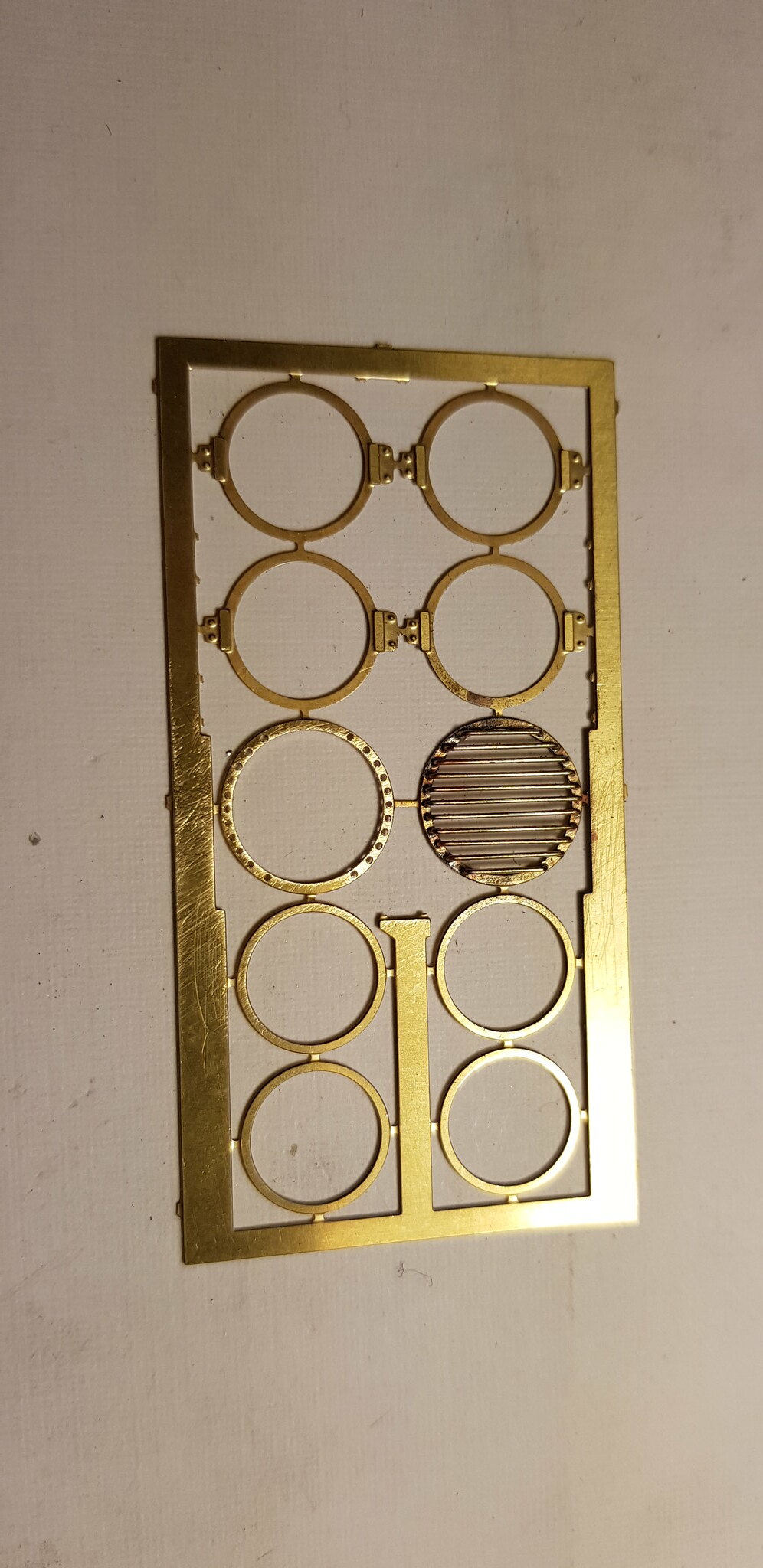

Nice brass window frames, window guard bar rings and handrail brackets on an etch.

So I amused myself for a couple of hours mounting tapered handrails with the brackets.

Next watch as I descend into madness making the rear cab window protection bars......

[

These mud hole covers were a bit vexing to fit. They required spinning in a mini drill to clean up, and then were awkward to position.

Nice brass window frames, window guard bar rings and handrail brackets on an etch.

So I amused myself for a couple of hours mounting tapered handrails with the brackets.

Next watch as I descend into madness making the rear cab window protection bars......

Nick Dunhill

Western Thunderer

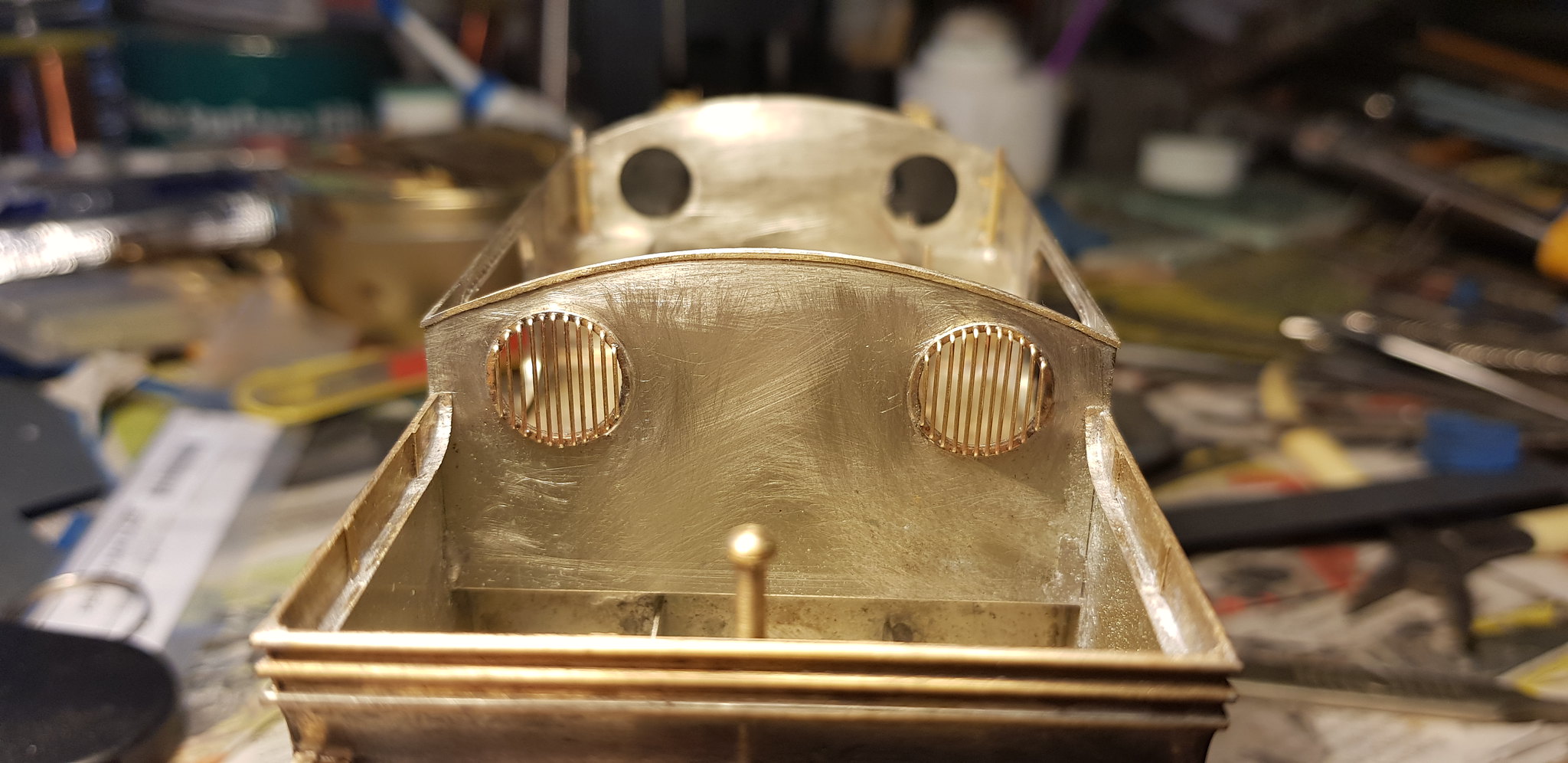

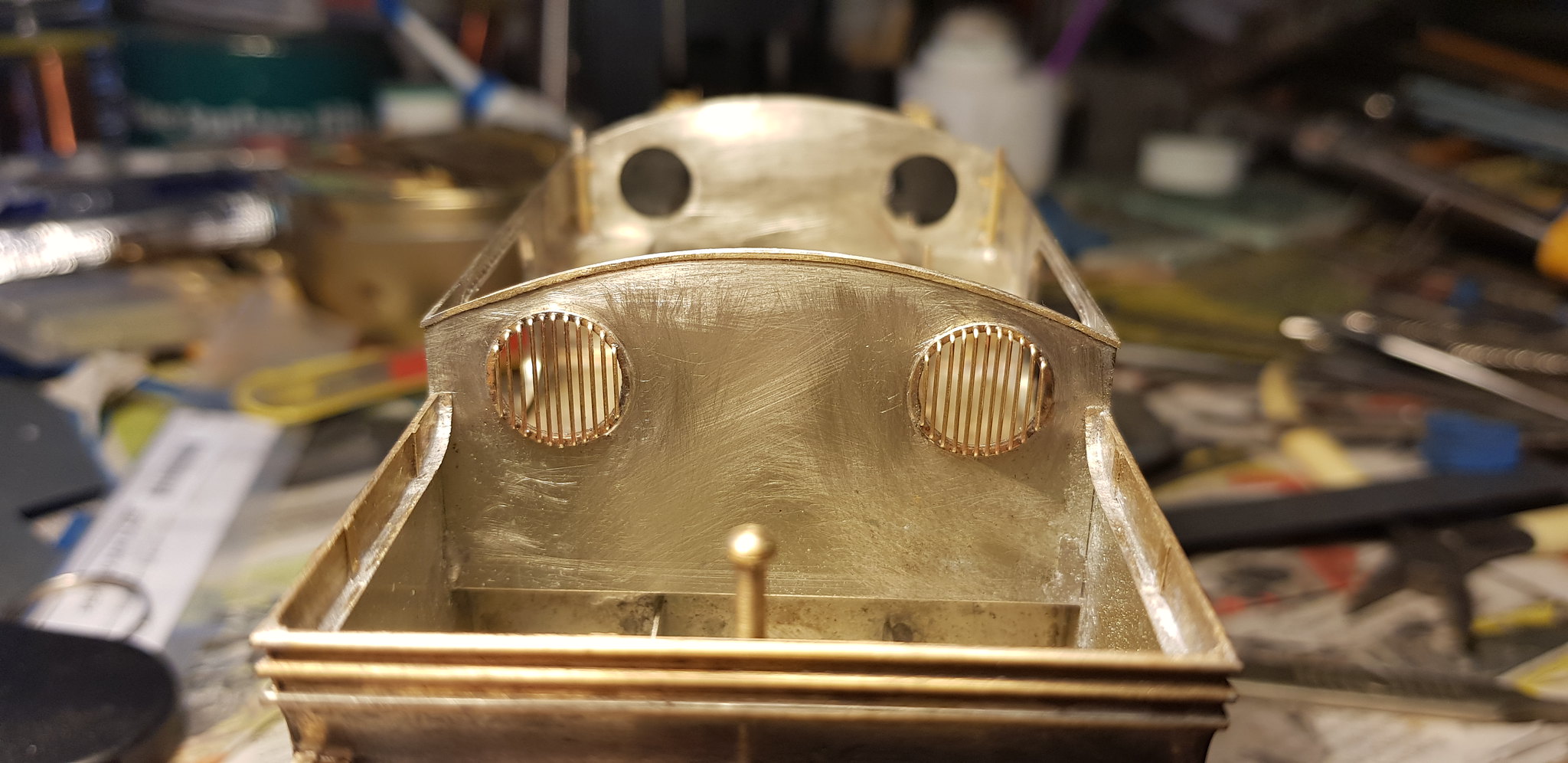

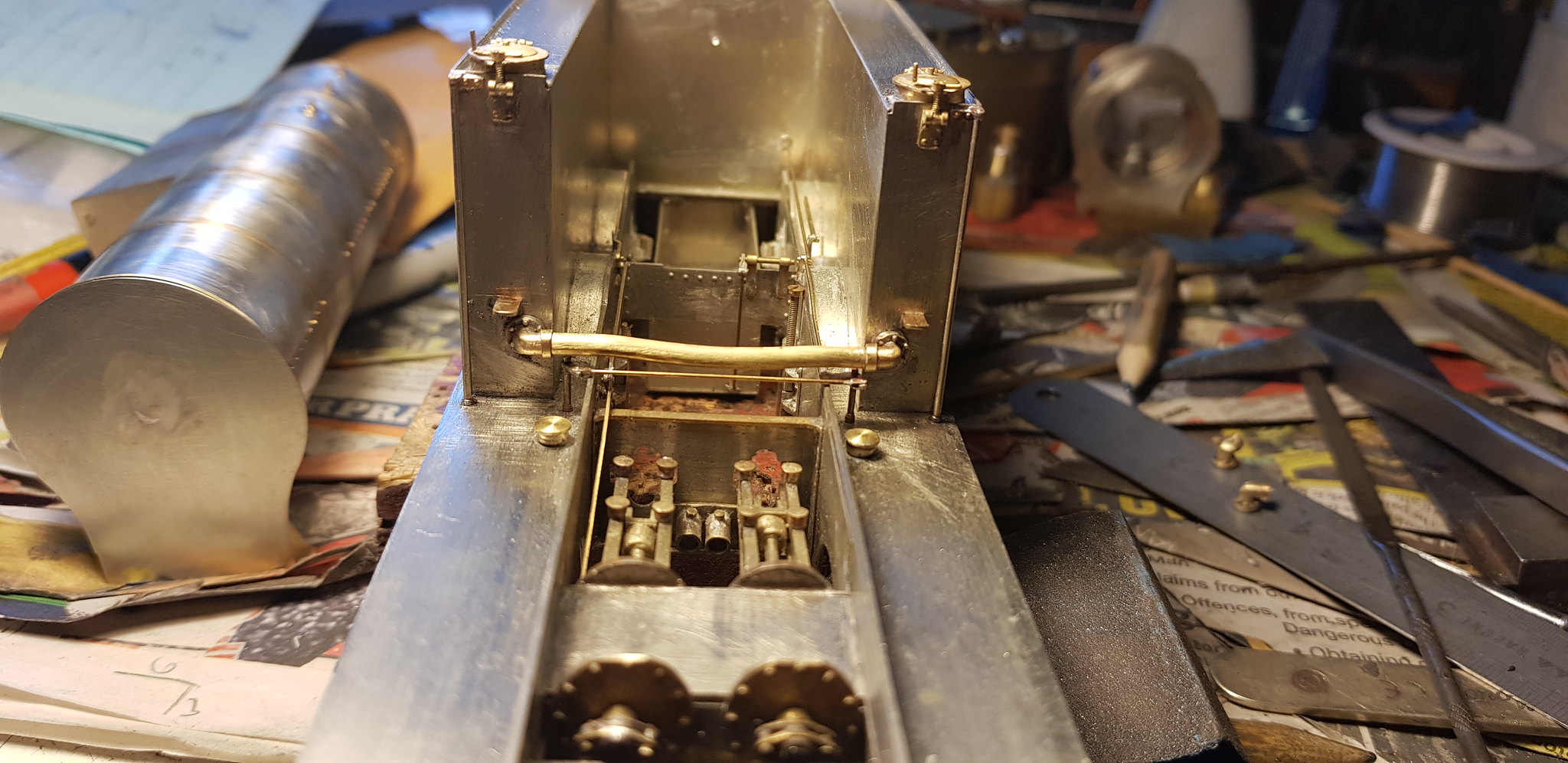

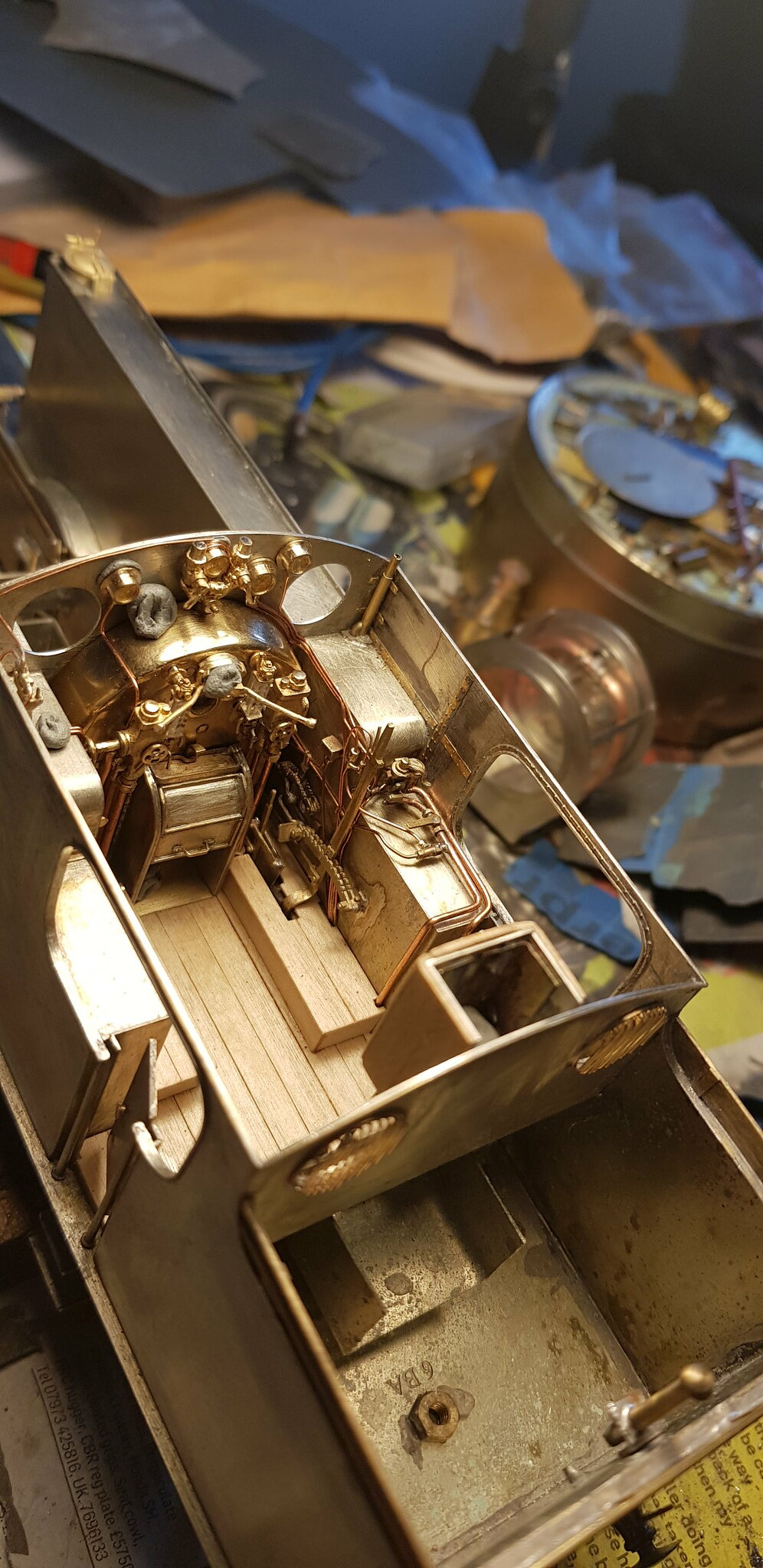

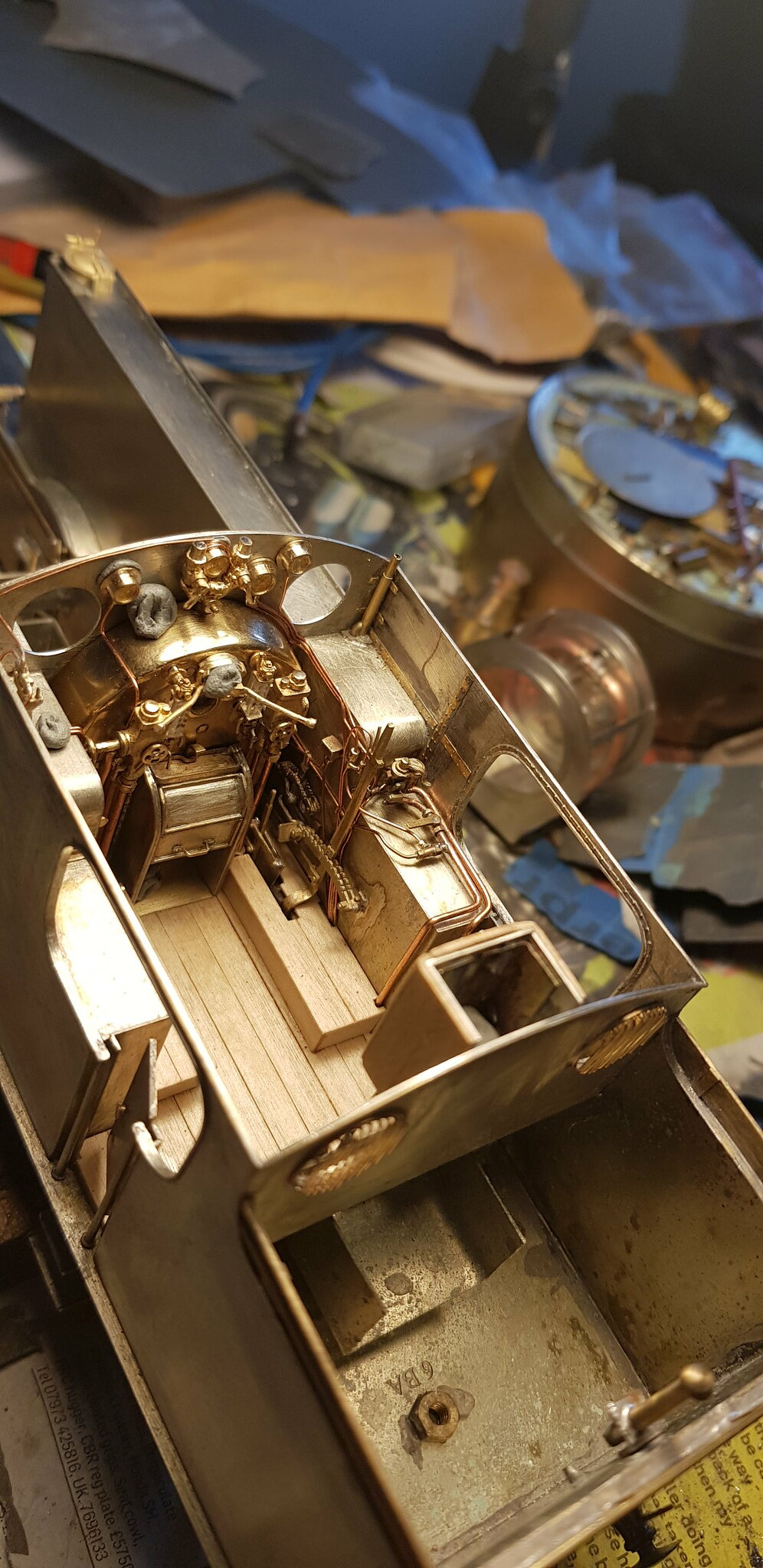

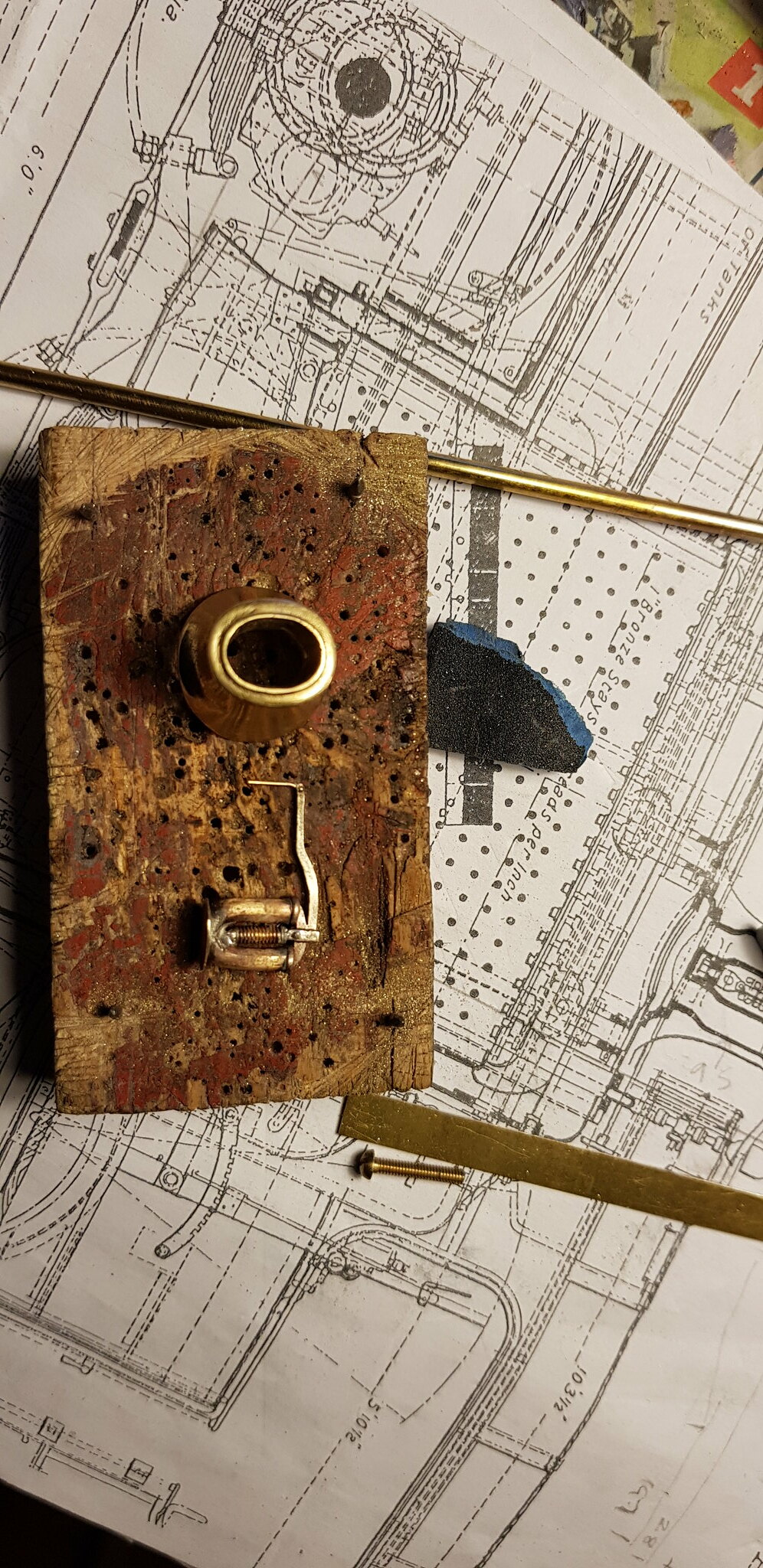

....right, I have now sorted out the cab windows. The windows are a sandwich of an outer round frame and an inner bigger frame around a disc of clear plastic. A fellow modeller has a 10 mm punch and has offered to lend it me to punch out plastic window discs, so more of that later. I would advise that the outer round frames have the cusps filed off and the window apertures in the cab front and rear should be dressed with a half round file so that the frame sits nicely inside it. Maybe this is best done before the cab is assembled. The plain outer frame sits within the aperture when finally fitted up, the window assemblies are pushed into place from the inside of the cab. The inner frame (sits on cab inner) has a small square of brass fitted to it to represent the open position bracket, and thin wire to represent the chain that holds a pin to lock the window open on the bracket. A similar bracket has been made for the underside of the cab roof which locates the window in the fully opened horizontal position, NER round cab windows are hinged at the top.

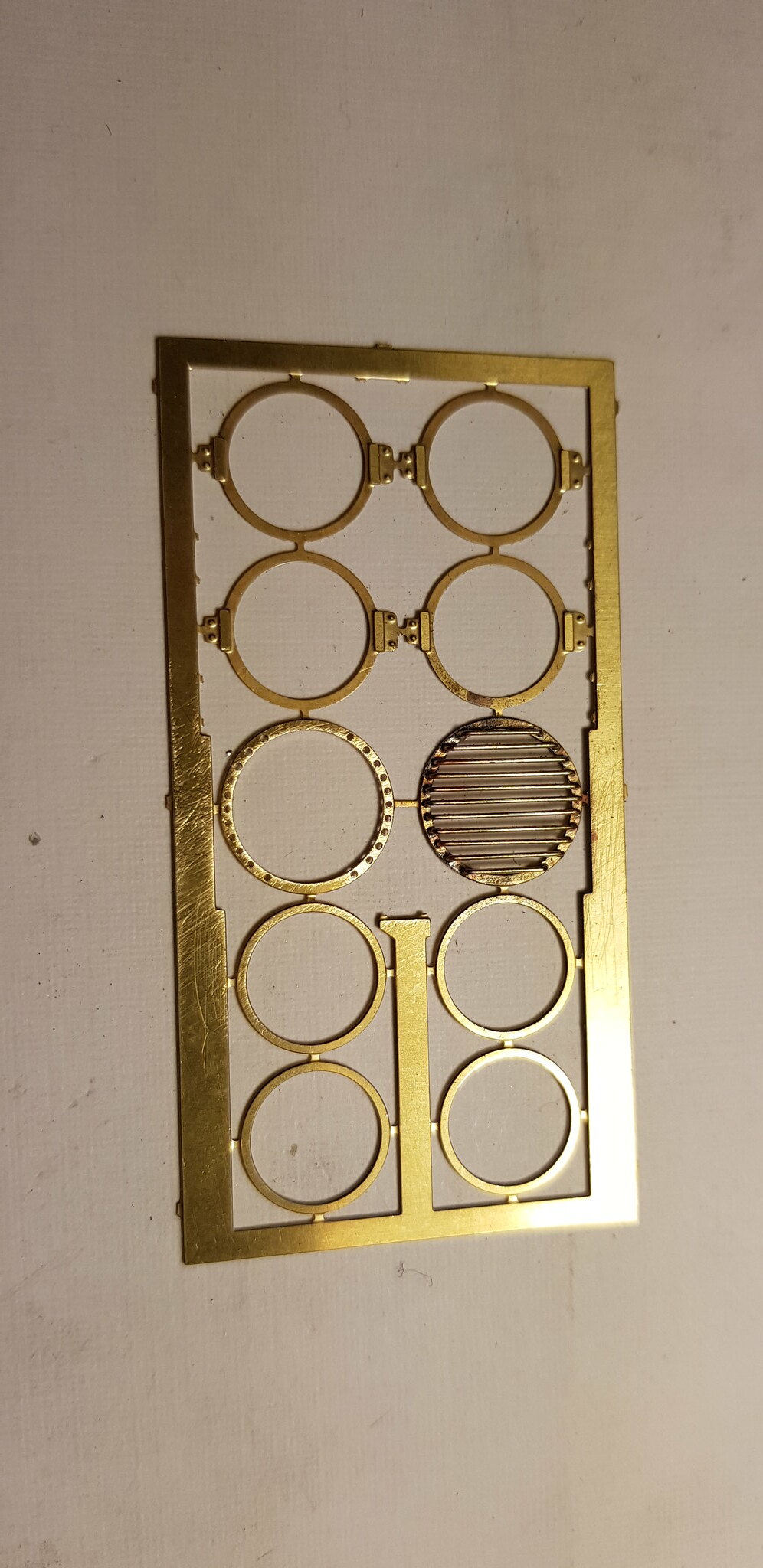

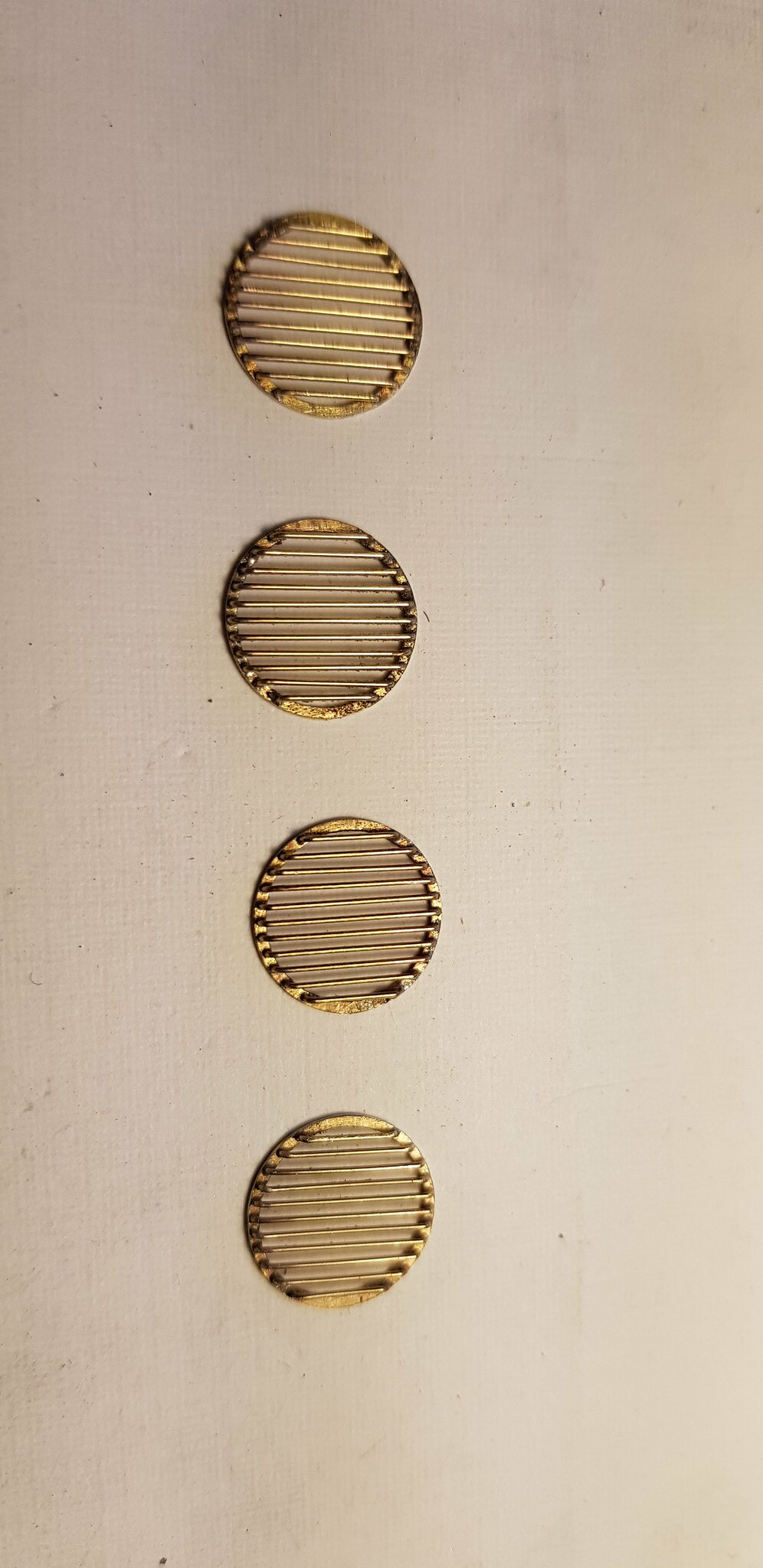

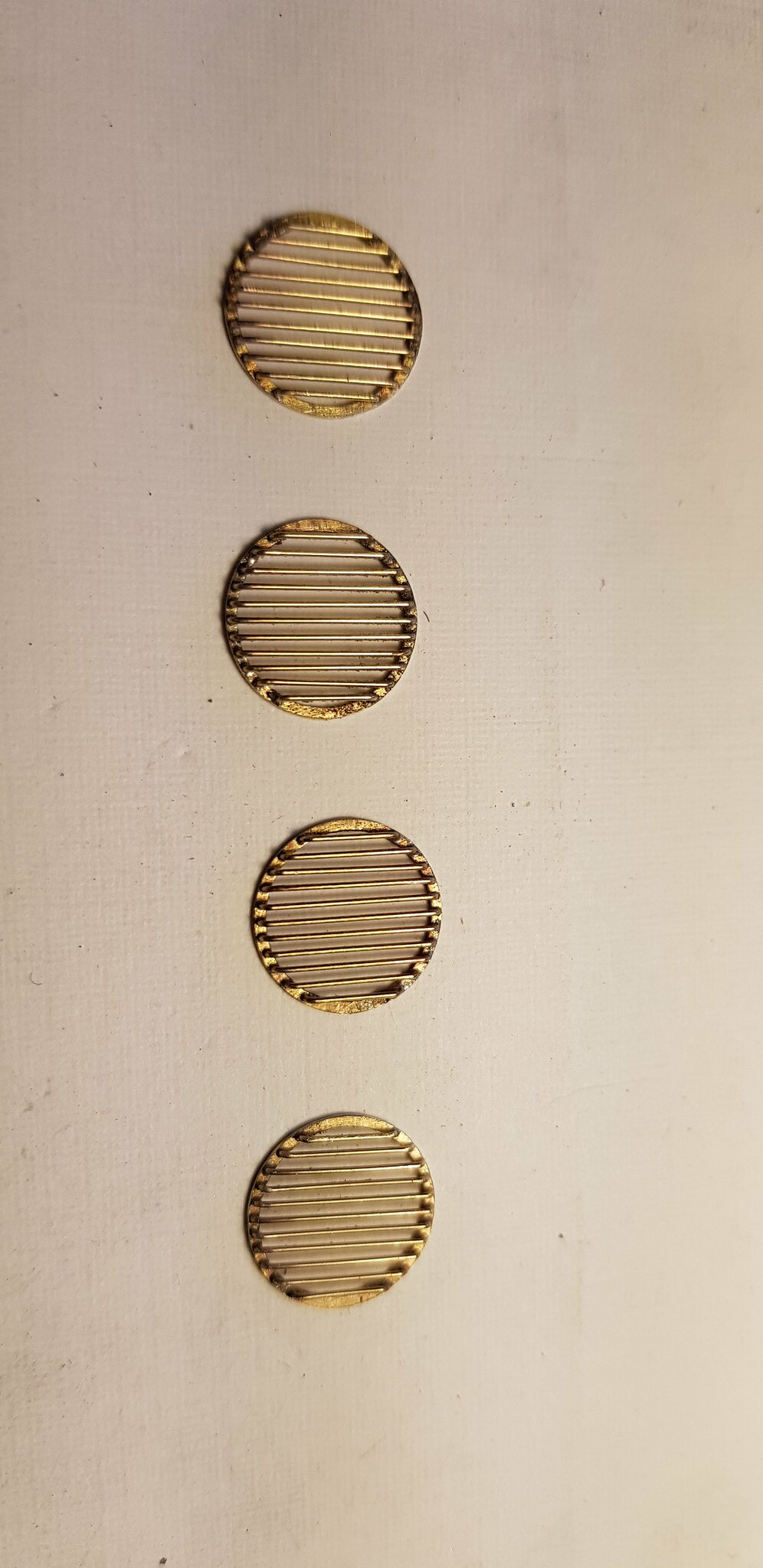

The etch includes a guard bar ring with half etched holes showing drilling locations. The holes were drilled out 0.4 mm (drilling and addition of bars was done whilst the part was still in the etch for ease of handling,) and the bars (44 for 4 frames!) were cut and bent from 0.376 mm rod. I thought this would be a nightmare, but once I got my eye in it was quick and easy, and quite therapeutic. A suitable width of 0.5 mm thick sheet was slipped between the bars and the ring, and the bars soldered in place on the rear. Soldering one end first allows a bit of spacing adjustment with some tweezers and then the other ends of the bars were soldered up.

The trickiest bit was actually soldering the finished bar assembly to the cab. It has to be centered on the aperture with the bars vertical. I used Blutac to hold it while checking.

Hopefully some smokebox progress next....

The etch includes a guard bar ring with half etched holes showing drilling locations. The holes were drilled out 0.4 mm (drilling and addition of bars was done whilst the part was still in the etch for ease of handling,) and the bars (44 for 4 frames!) were cut and bent from 0.376 mm rod. I thought this would be a nightmare, but once I got my eye in it was quick and easy, and quite therapeutic. A suitable width of 0.5 mm thick sheet was slipped between the bars and the ring, and the bars soldered in place on the rear. Soldering one end first allows a bit of spacing adjustment with some tweezers and then the other ends of the bars were soldered up.

The trickiest bit was actually soldering the finished bar assembly to the cab. It has to be centered on the aperture with the bars vertical. I used Blutac to hold it while checking.

Hopefully some smokebox progress next....

Last edited:

Nick Dunhill

Western Thunderer

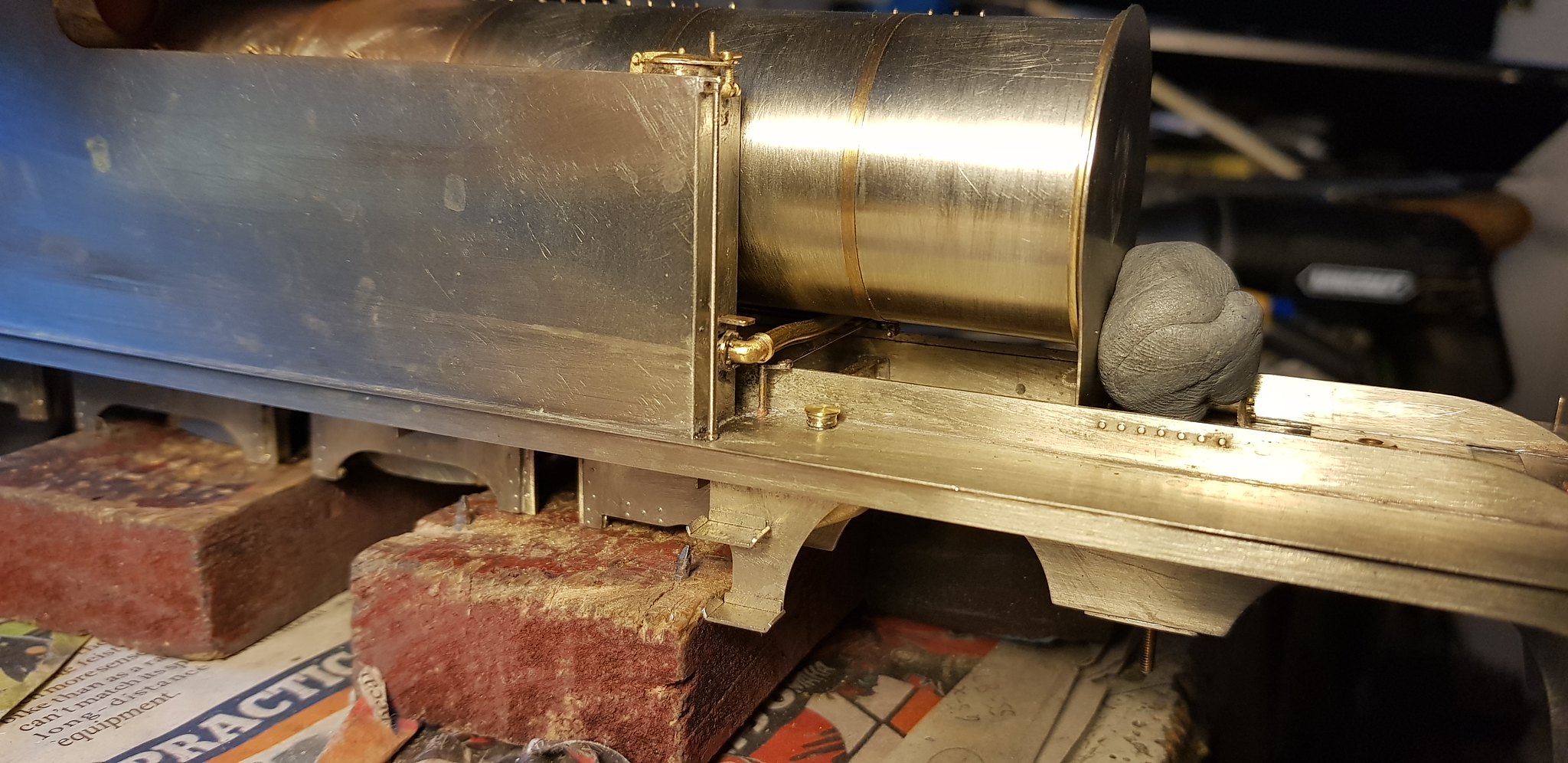

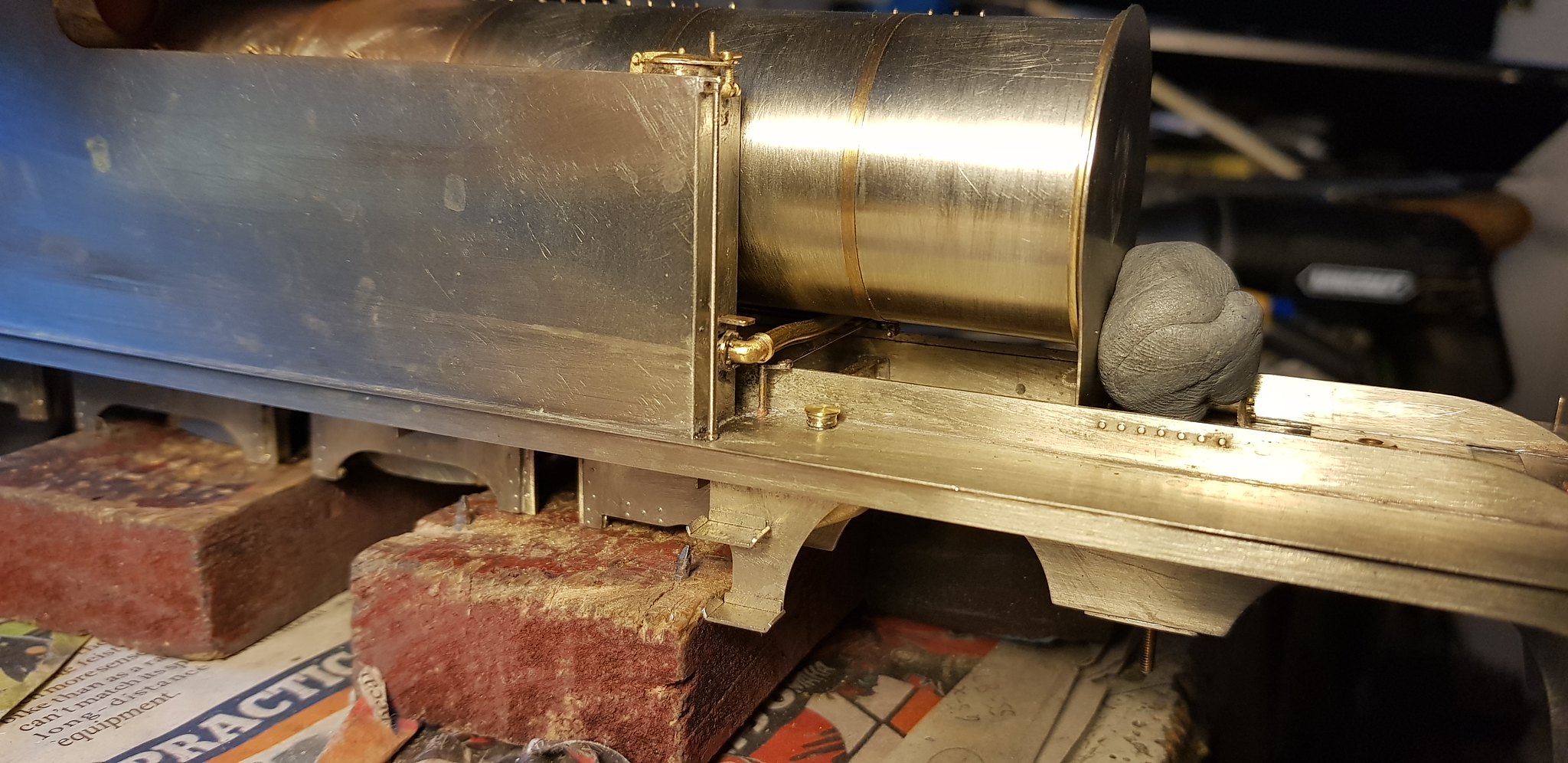

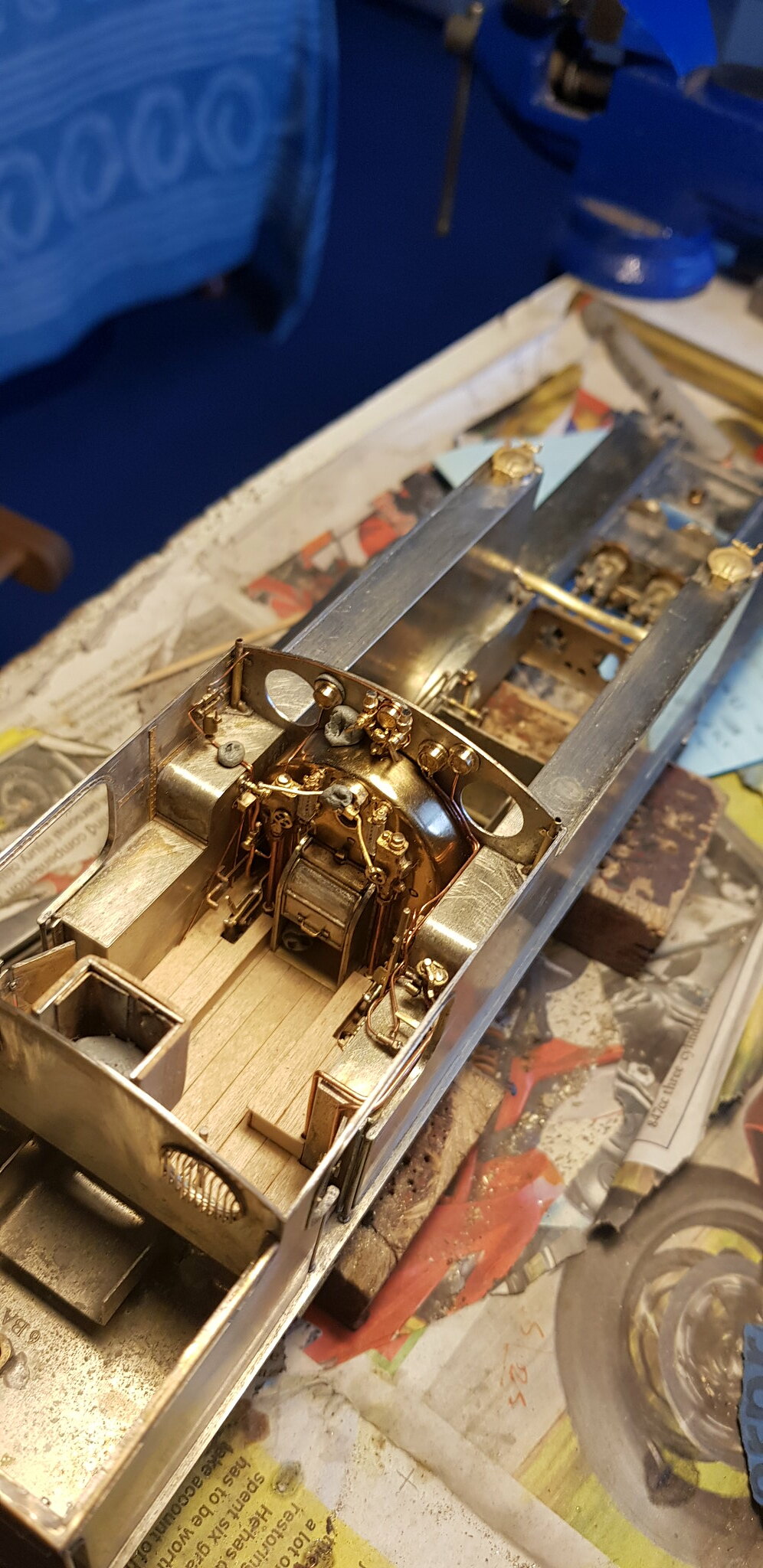

....just a little finishing strip. The Ws had a brass cover between the boiler and smokebox (it hid some bracketing) which of course in NER days was polished. Mine is made from 1 x 1 mm square brass bar curved in my rolling bars and with one corner radiused off. It was made oversize and cut to the correct circumference, you have to manipulate it a bit to fit the end of the boiler snugly.

Next more smokebox work......

Next more smokebox work......

Nick Dunhill

Western Thunderer

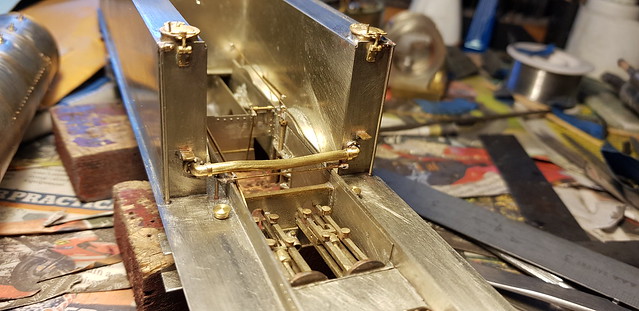

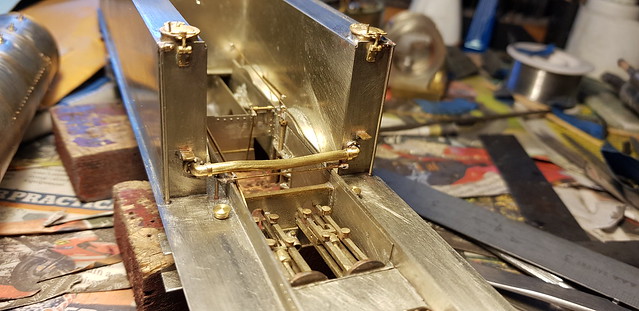

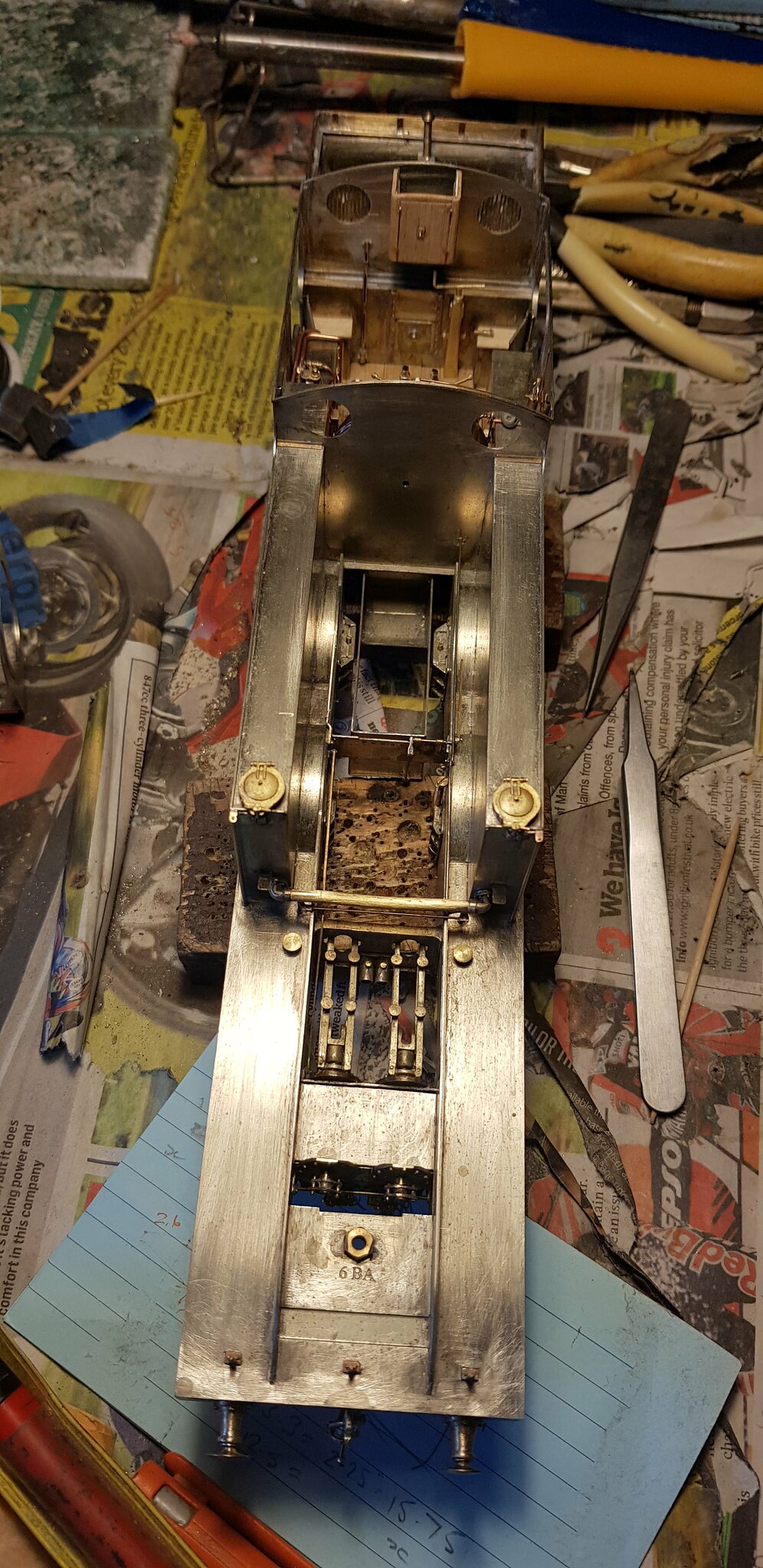

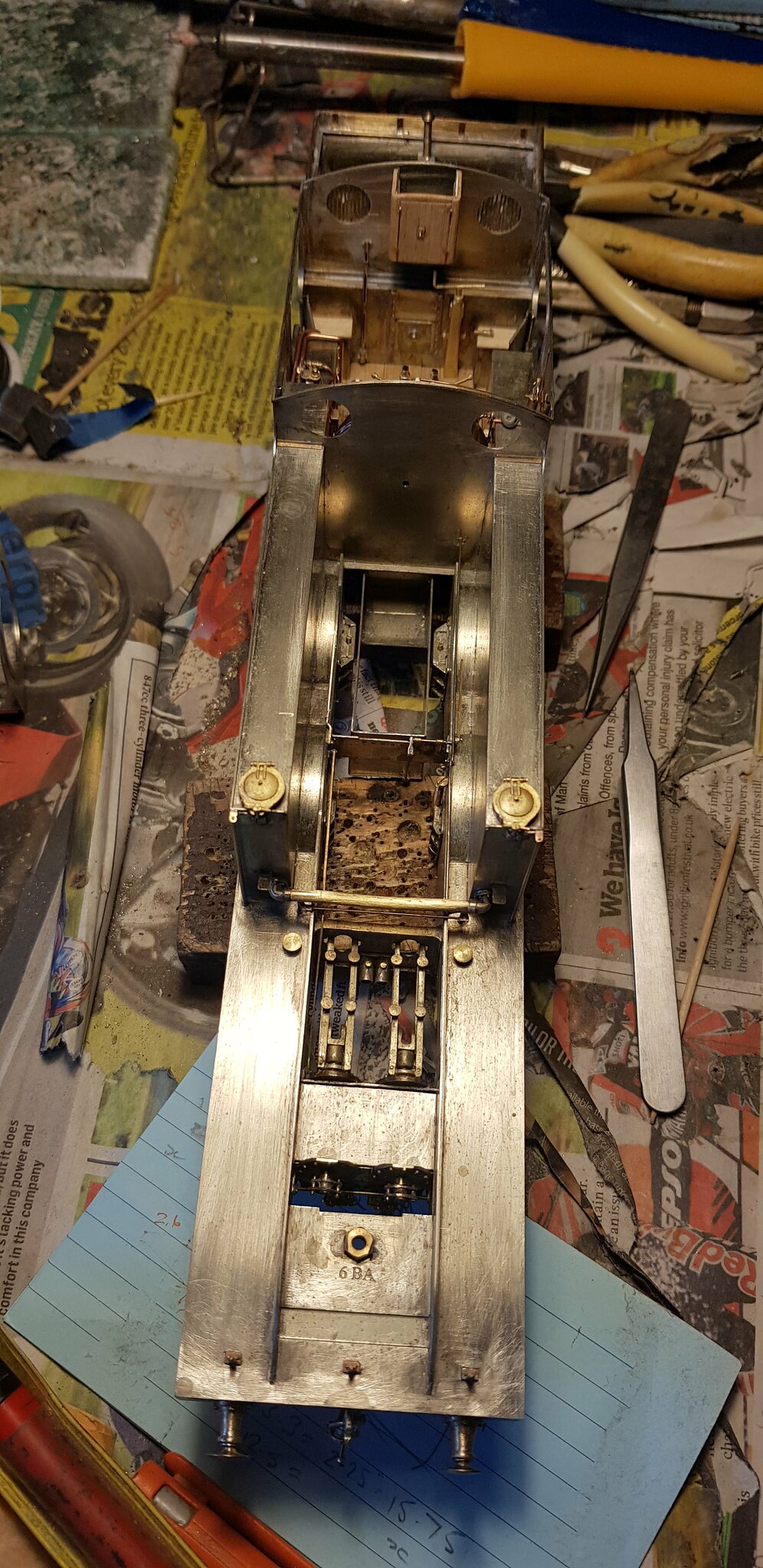

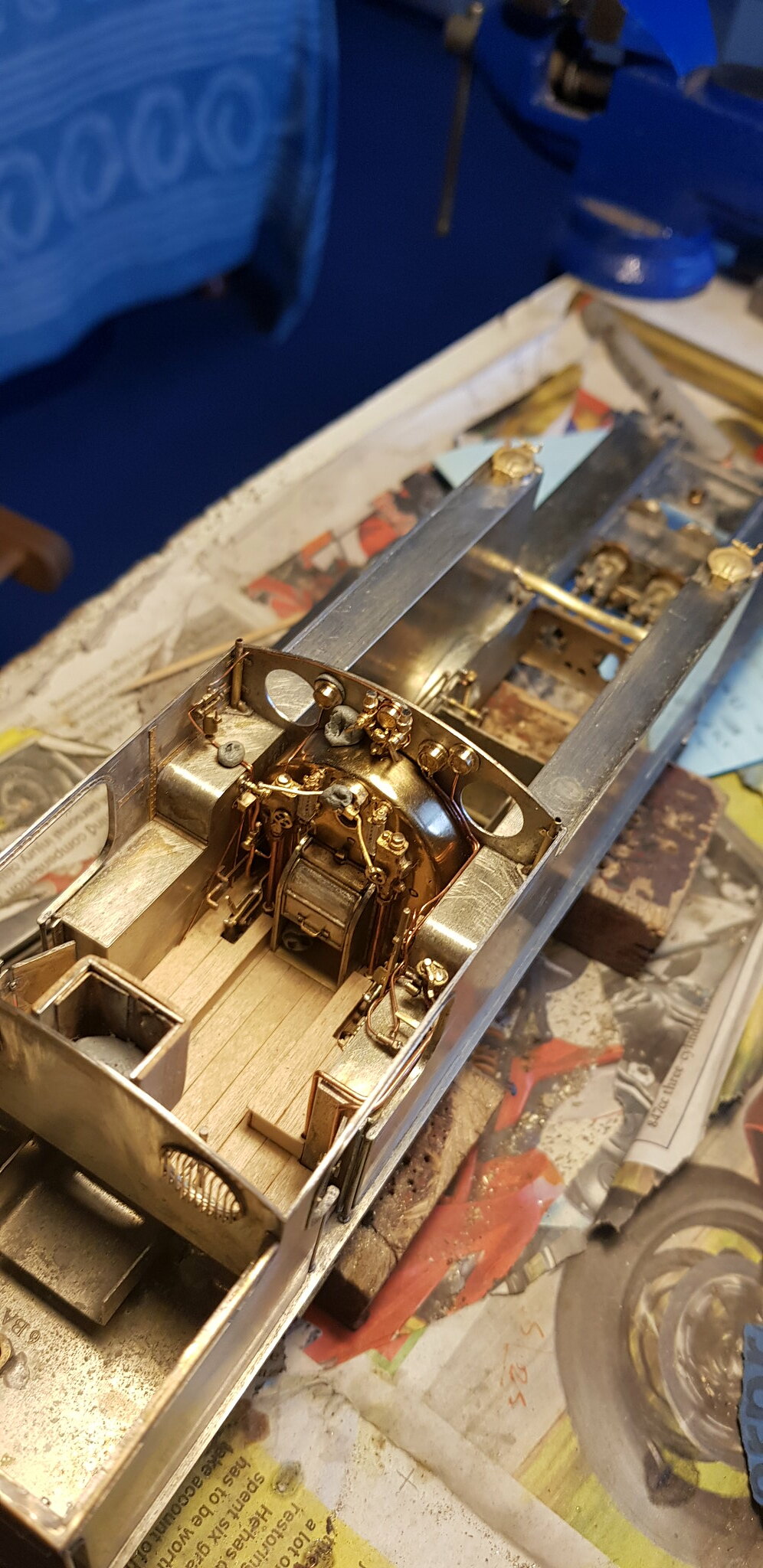

.....I thought it would be a good thing to finish the tank fronts. Footsteps were made from waste strip and attached. The balance pipe looked a bit more tricky. The elbows at either end were made by cutting a 90 deg wedge, 2/3 way through a section of 2.5 mm rod. The rod can be then bent to a right angle and soldered up, no annealing needed. The round flanges were made by sandwiching two thin washers together on a short bit of 2.5 mm rod. The washers were spun in a minidrill and filed to the correct diameter. The resulting flange was drilled and furnished with screws from the Scale Hardware range. The other joining flange was cut from 2.5 mm ID thin walled tube. The balance pipe was carefully fashioned from more 2.5 mm rod, and the finished pipe carefully assembled on the model. It was VERY tricky.

Next, Kettering...........

Next, Kettering...........

Yorkshire Dave

Western Thunderer

Next, Kettering...........

I think the exhibitors and traders may outnumber the visitors this weekend.......

oldravendale

Western Thunderer

You are quite correct, Dave, but we have to be there for our wonderful public.

(Well, I'm hoping so, but the blizzard has restarted after a lull of about an hour, so we'll just have to see. In any event, as we are so geographically split one or two of our number should make it).

Brian

(Well, I'm hoping so, but the blizzard has restarted after a lull of about an hour, so we'll just have to see. In any event, as we are so geographically split one or two of our number should make it).

Brian

Nick Dunhill

Western Thunderer

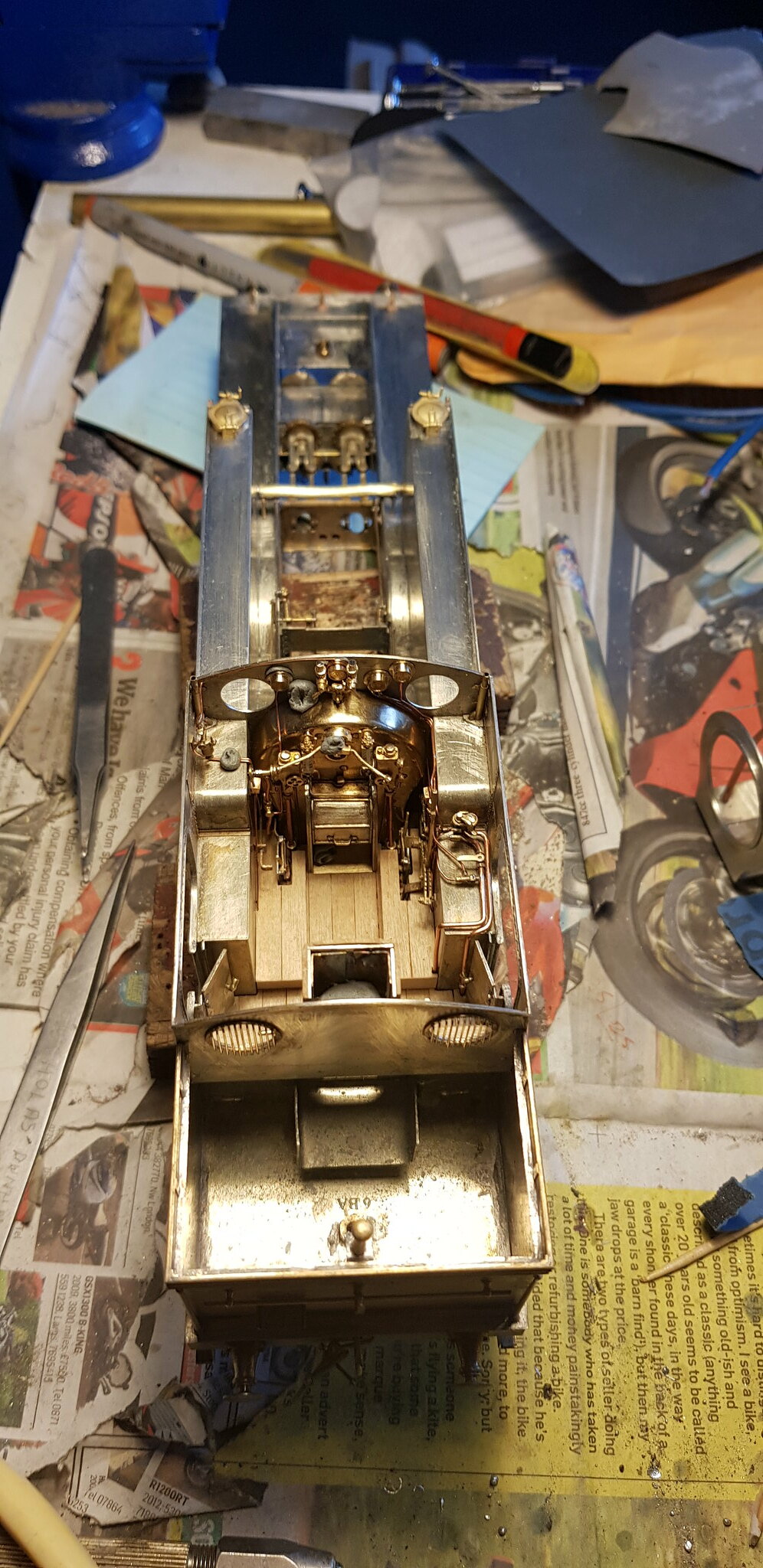

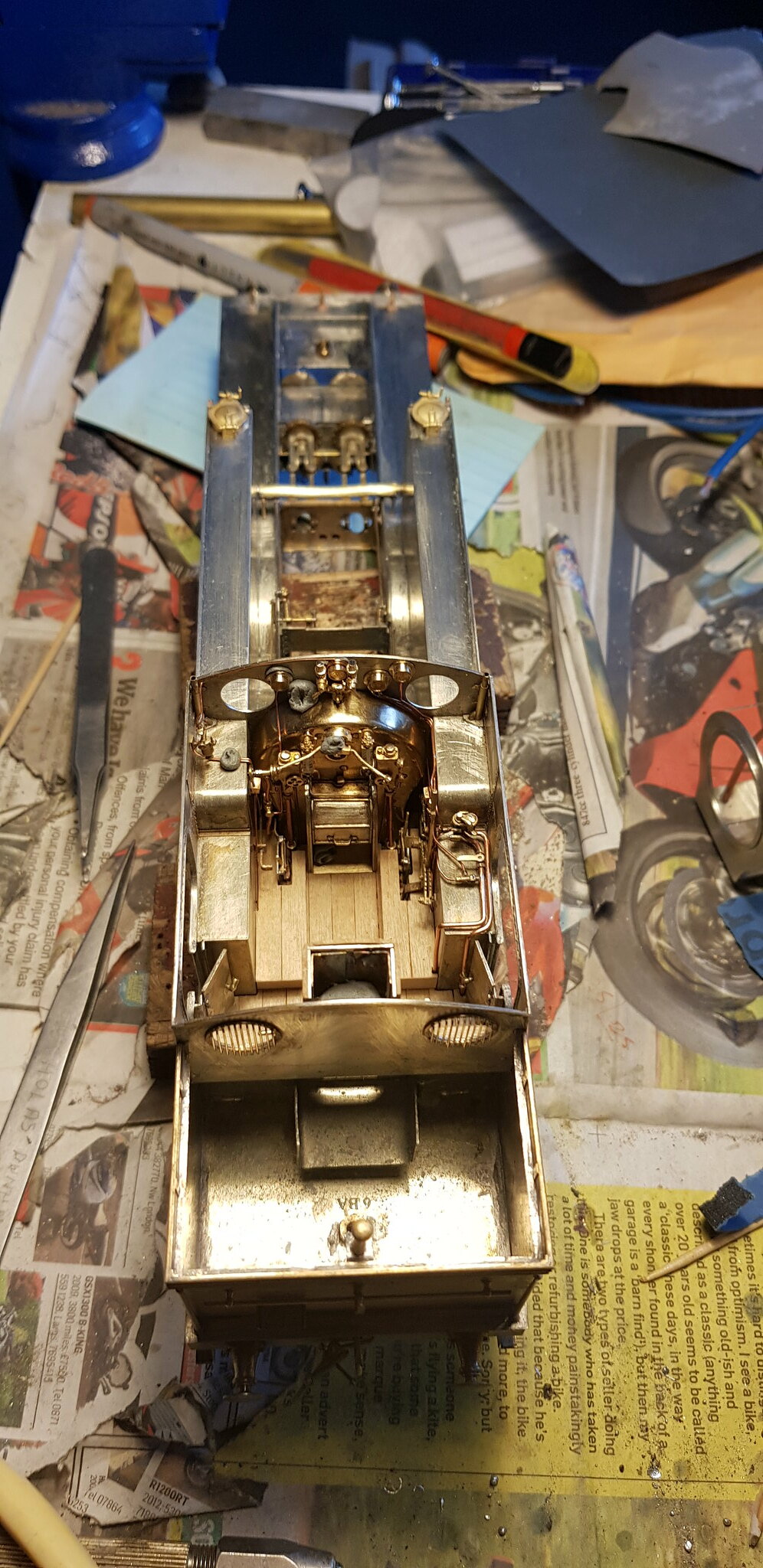

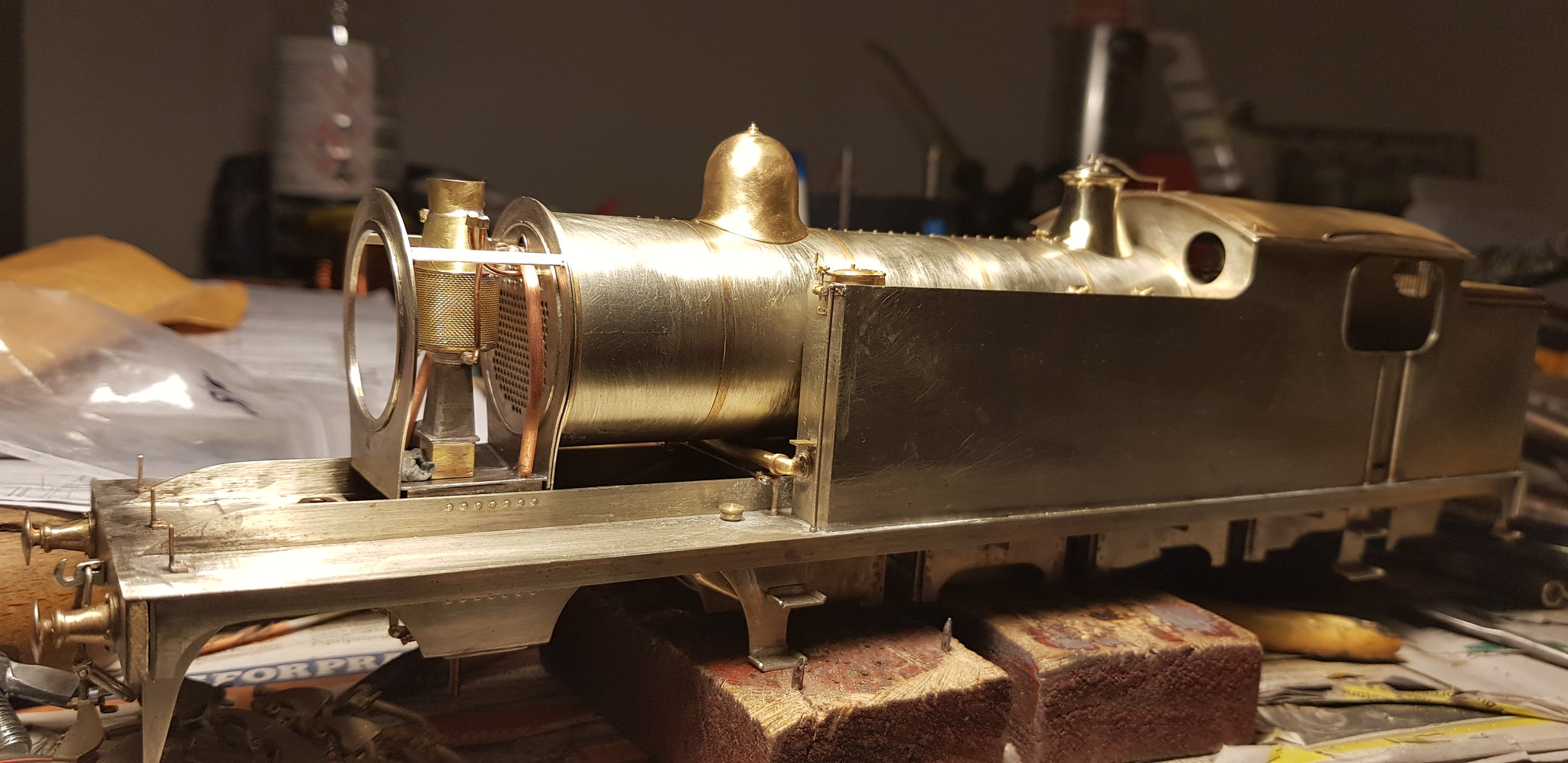

..well I'll be going, not too much of a problem from Sheffield. I have assembled one of the Ws for a bit of show-and-tell. If you can't make it maybe these pics'll keep you warm.

oldravendale

Western Thunderer

Still hoping to see you on Saturday, Nick. Weather here remains a bit grim, though.

Brian

Brian

mickoo

Western Thunderer

If you're going down tomorrow, first round at the bar on Warren then..well I'll be going, not too much of a problem from Sheffield.

Tim Watson

Western Thunderer

Firebox door area looks like a fish and chip shop fryer! Better than Beeson.

Tim

Tim

Nick Dunhill

Western Thunderer

....Tom Burnham sent me the following picture of a Ramsbottom SV cover and I realised the casting I had was incorrectly filled in at the top. I decided to improve the situation.

I opened up the top of the cover casting with rotary files and burrs in a mini drill and made a proper Ramsbottom safety valve using the top of the casting supplied. I think it looks a bit better.

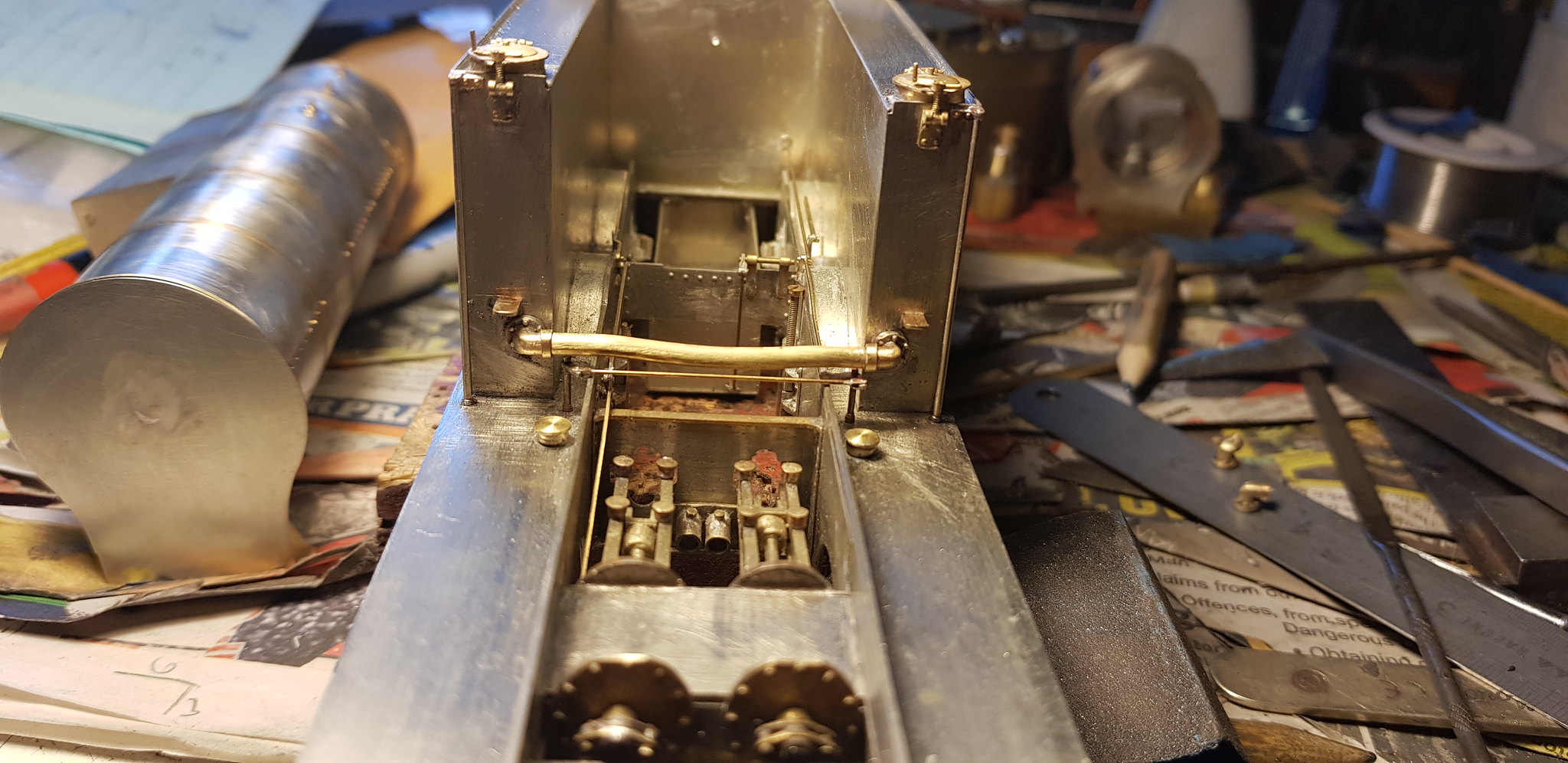

I also added the blast pipe, spark arrestor and petticoat pipe to the smokebox with some more piping for the blower and Westinghouse pump (plus other odds and sods.)

I now await the arrival of a 3D printed smokebox door to complete the smokebox and then boiler.....

I opened up the top of the cover casting with rotary files and burrs in a mini drill and made a proper Ramsbottom safety valve using the top of the casting supplied. I think it looks a bit better.

I also added the blast pipe, spark arrestor and petticoat pipe to the smokebox with some more piping for the blower and Westinghouse pump (plus other odds and sods.)

I now await the arrival of a 3D printed smokebox door to complete the smokebox and then boiler.....

Rob Pulham

Western Thunderer

Martin Shaw

Western Thunderer

Awesome is much overused to describe objects that don't invoke awe, this really is though, probably some of the best modelling I have ever seen.

Regards

Martin

Regards

Martin

Len Cattley

Western Thunderer

Lovely workmanship there Nick, I wish I could model half as good as you.

Len

Len