Simon

Flying Squad

And presumably easily scale-able to 1/32 in the world of 3d printing.

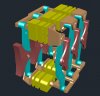

Your sprung option is what I do in G1. One thought if you are going down that route is to create a recess in the top surface of the axle box in which to partly "lose" a spring, possibly combined with a slightly lower top surface, this enables a functional coil spring to operate "out of sight" when viewed from normal angles.

Certainly in the G1 world, some stunning models are badly let down by not thinking this bit through and having visible non prototypical coil springs on view, I think the otherwise fabulous "Golden Age" coaches suffer from this problem.

All that said, if one were really clever then the leaf springs would actually work - I don't attempt it myself!

Don't you chaps need a few LSWR and MR axle boxes.......

Simon

Your sprung option is what I do in G1. One thought if you are going down that route is to create a recess in the top surface of the axle box in which to partly "lose" a spring, possibly combined with a slightly lower top surface, this enables a functional coil spring to operate "out of sight" when viewed from normal angles.

Certainly in the G1 world, some stunning models are badly let down by not thinking this bit through and having visible non prototypical coil springs on view, I think the otherwise fabulous "Golden Age" coaches suffer from this problem.

All that said, if one were really clever then the leaf springs would actually work - I don't attempt it myself!

Don't you chaps need a few LSWR and MR axle boxes.......

Simon

..... will be placing order today!

..... will be placing order today!

.

. Surely it'd be a nice surprise for somebody at Christmas?

Surely it'd be a nice surprise for somebody at Christmas?

.

.