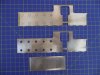

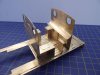

Some more progress on the M7. The boiler/smoke box assembly are fixed permanently at this stage, but it's a good idea beforehand to make the openings in the footplate to accommodate the coupling rod oil pot on the driving axle (pictured later)

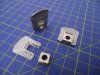

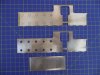

I then moved onto the tanks/cab/bunker. The loco i'm building was fitted with water heating apparatus from new, which lead to the tanks obviously containing hot water for efficiency purposes. To guard against this blistering the paint on the tanks and members of the public potentially burning themselves they were fitted with cladding plates. These are provided in the kit and Martin offers a neat way of attaching them seamlessly. The rear of the tank is marked out for a 3/16 drill and you have to turn the thing to swiss cheese first. Next you tack the cladding plate in place and then flood solder in from the rear, which makes for a nice tidy job. A good job really as otherwise all the water will run out

The fireman's side assembled, the hole in the tank front is to accept the heating pipe from the smoke box

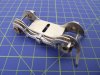

Martin then advises to detail the boiler and smoke box prior to fitting the tank assemblies. The piano front took a little time forming but better to take your time and get this spot on as it's forms the face. Once this was fitted the sanding controls and riveted sandbox angle followed, then some lovely lost wax castings. I particularly like the piano front handles, although I pinged one off the bench and it took me about twenty minutes to find it

Finally here I fitted the handrails. a blower valve casting is provided, which again is spot on;

The first picture shows the only section of handrail that is permanently fixed at the moment, the remainder is removable to assist lining. I made the front section in three parts to make it easier to form. Next job here will be lamp irons but i've yet to decide whether to replace the kit ones with LG castings, as they do look very nice. I've also tacked the driver's side tank on but i'll post more up when i'm further on with this part of the build,

Mick.R

Hi Peter,

Hi Peter,