richard carr

Western Thunderer

I bought an MMP Class 56 from Mickoo a bout 2 years ago now and have been itching to build it if I'm being honest.

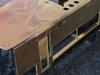

So I made a start in Chicago this week on the bogies

The bogie frames come in 4 main pieces, a top a bottom and two sides, there is a half etched line where the sides "clip" in to. The sides are handed and the top and bottom are not flat there are some subtle bend to make on the bottom and some more obvious ones on the top that match the profile of the sides. Folding this requires a considerable amount of care, it's very easy to get this slightly wrong and find that it doesn't fit. It does fit perfectly you just need to bend everything perfectly to get it to fit perfectly.

Then you have to solder it up, I used some old slater's plastic wagon wheel bearing boxes to hold the parts while I did the soldering to avoid too many burnt fingers.

I started by fitting the sides to the top. You make the bends in the top easily and get those to fit the sides.

I then found the easiest way to do this was to hold the side in the half etched line then bend the front round until it clipped in place, then you could tack solder it in place. Then try and fold round the other end and get that to clip in place and be perfectly square.

It all ends up very nice indeed.

Fortunately this is one of the kits covered on Building O Gauge online so lots of help there.

Richard

So I made a start in Chicago this week on the bogies

The bogie frames come in 4 main pieces, a top a bottom and two sides, there is a half etched line where the sides "clip" in to. The sides are handed and the top and bottom are not flat there are some subtle bend to make on the bottom and some more obvious ones on the top that match the profile of the sides. Folding this requires a considerable amount of care, it's very easy to get this slightly wrong and find that it doesn't fit. It does fit perfectly you just need to bend everything perfectly to get it to fit perfectly.

Then you have to solder it up, I used some old slater's plastic wagon wheel bearing boxes to hold the parts while I did the soldering to avoid too many burnt fingers.

I started by fitting the sides to the top. You make the bends in the top easily and get those to fit the sides.

I then found the easiest way to do this was to hold the side in the half etched line then bend the front round until it clipped in place, then you could tack solder it in place. Then try and fold round the other end and get that to clip in place and be perfectly square.

It all ends up very nice indeed.

Fortunately this is one of the kits covered on Building O Gauge online so lots of help there.

Richard