Nick Dunhill

Western Thunderer

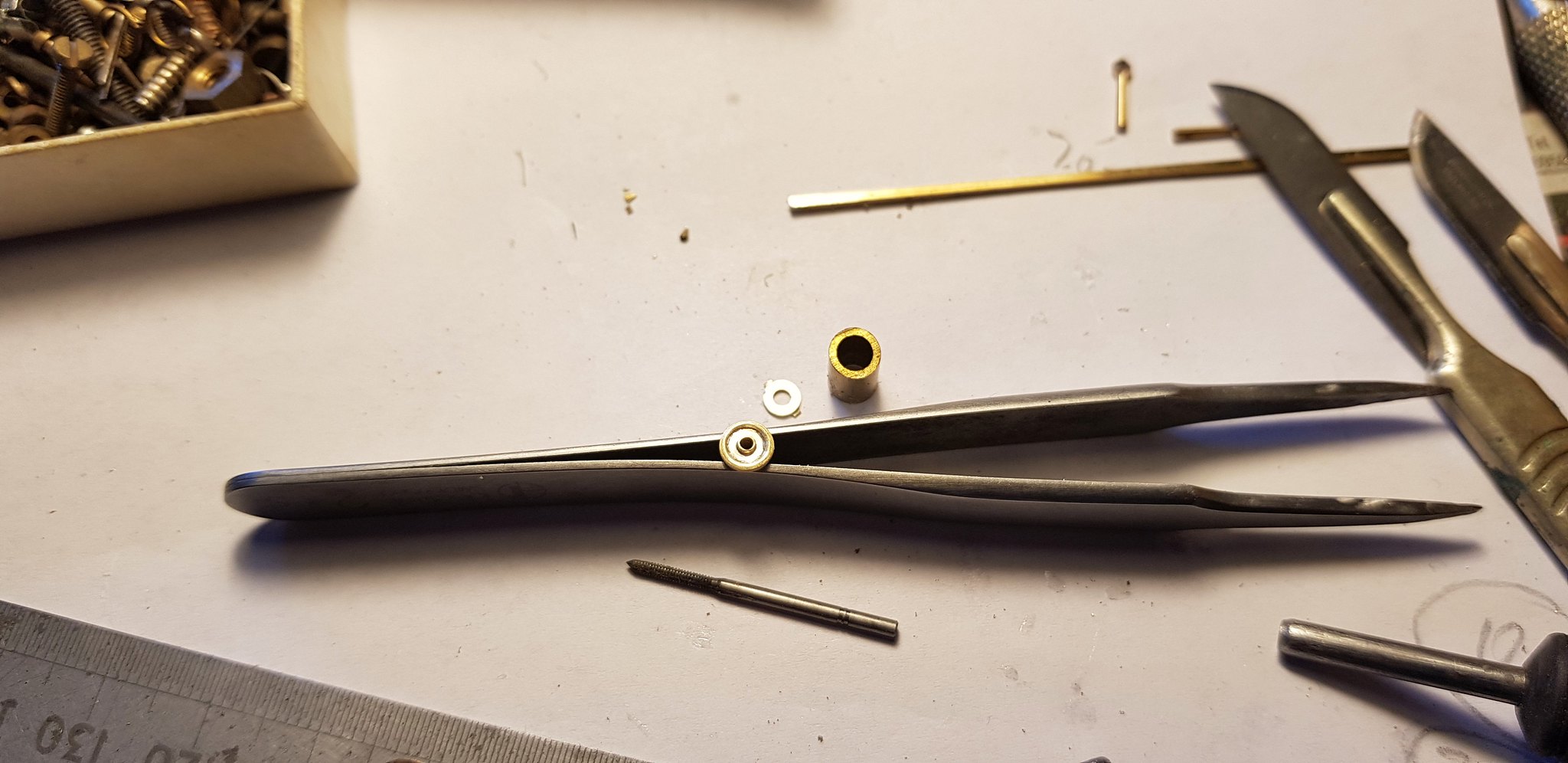

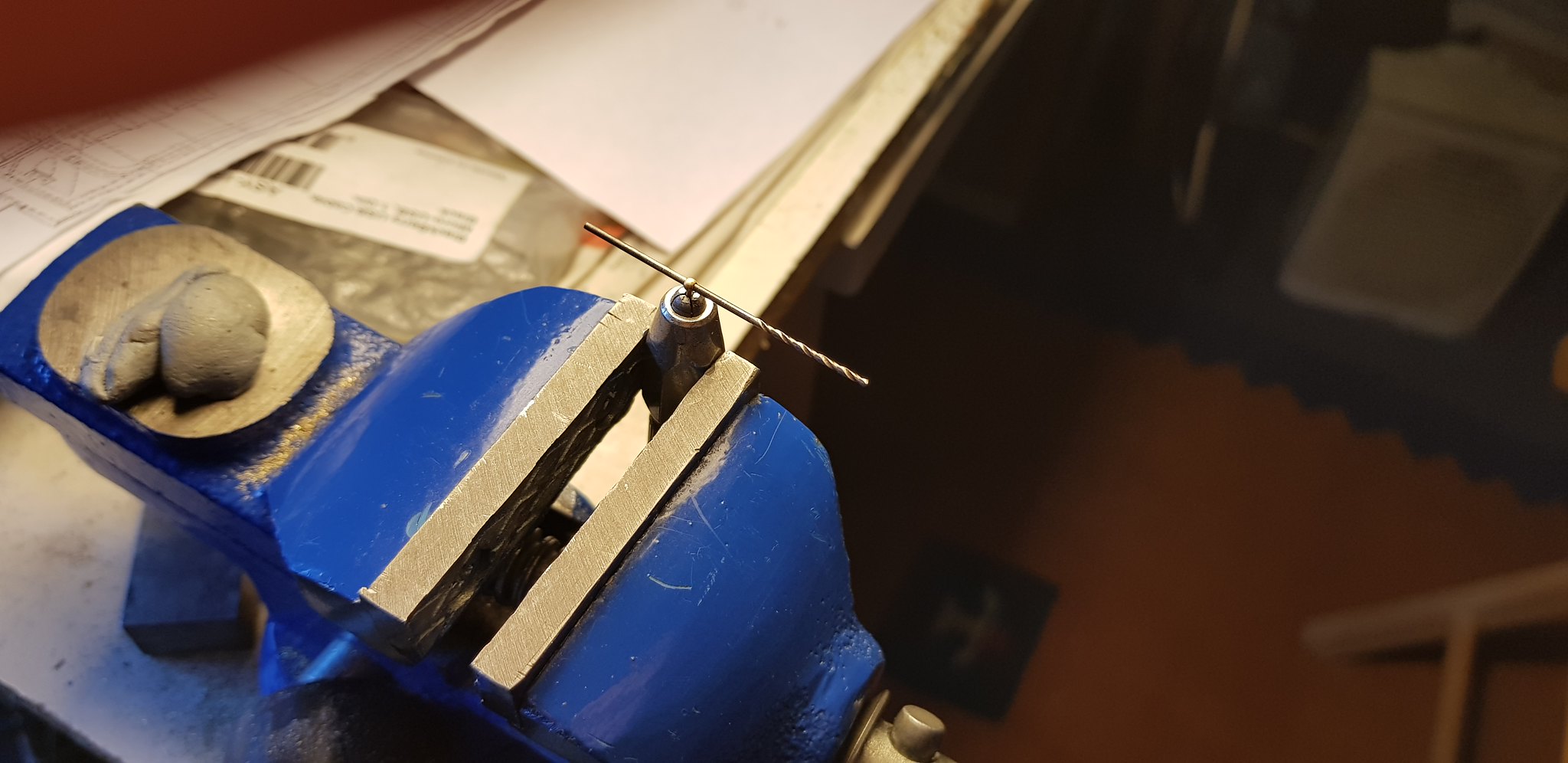

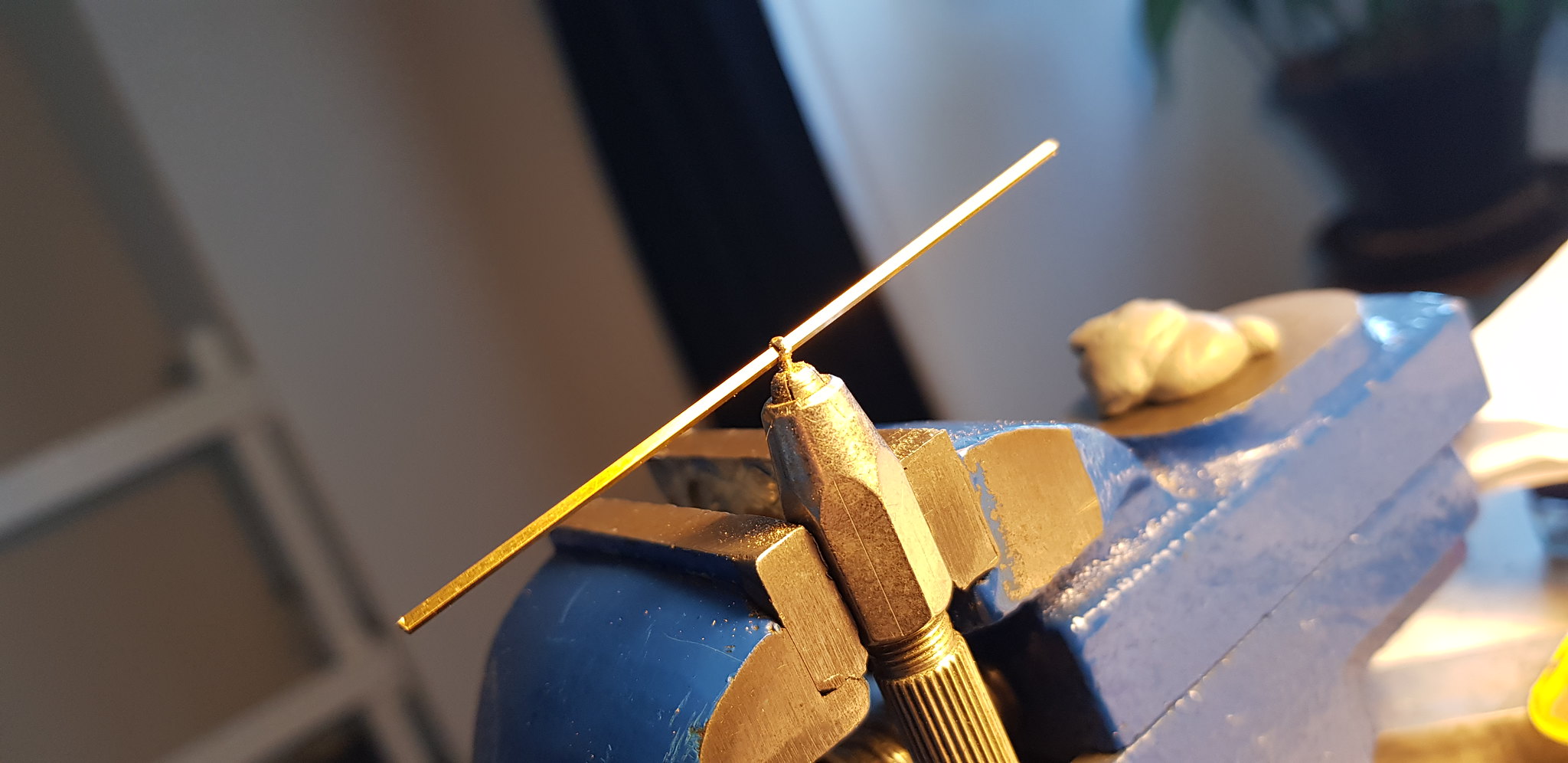

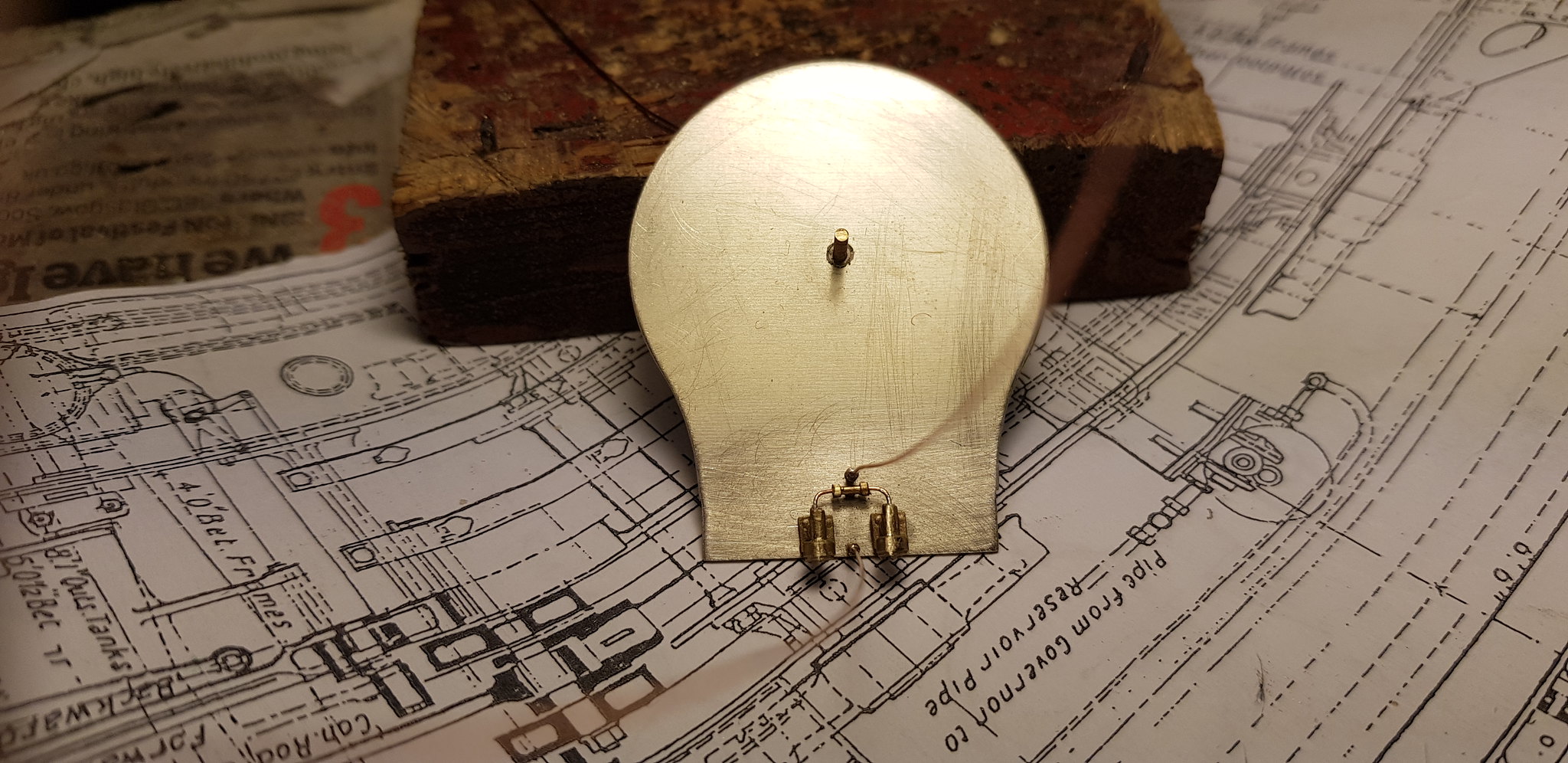

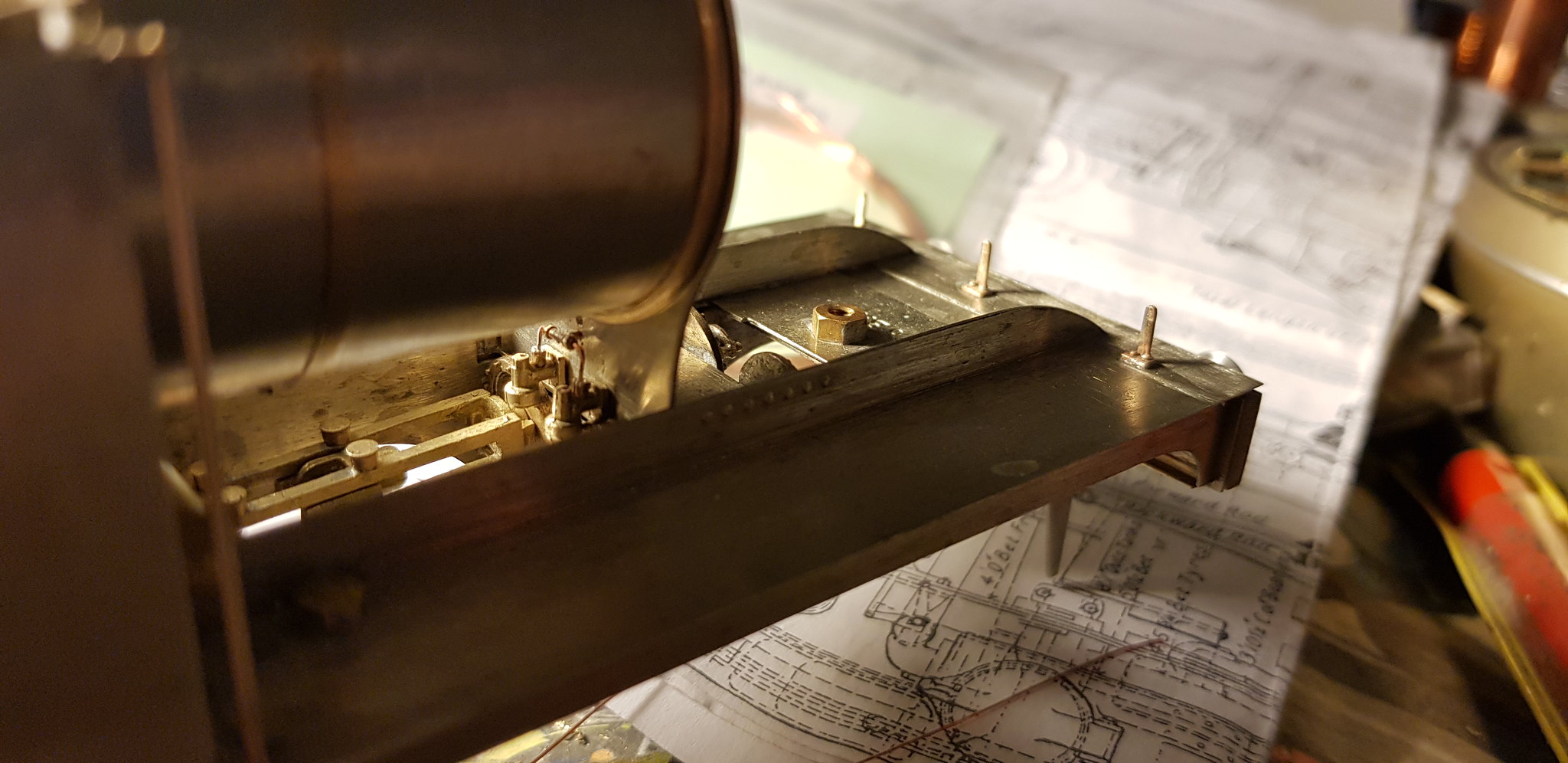

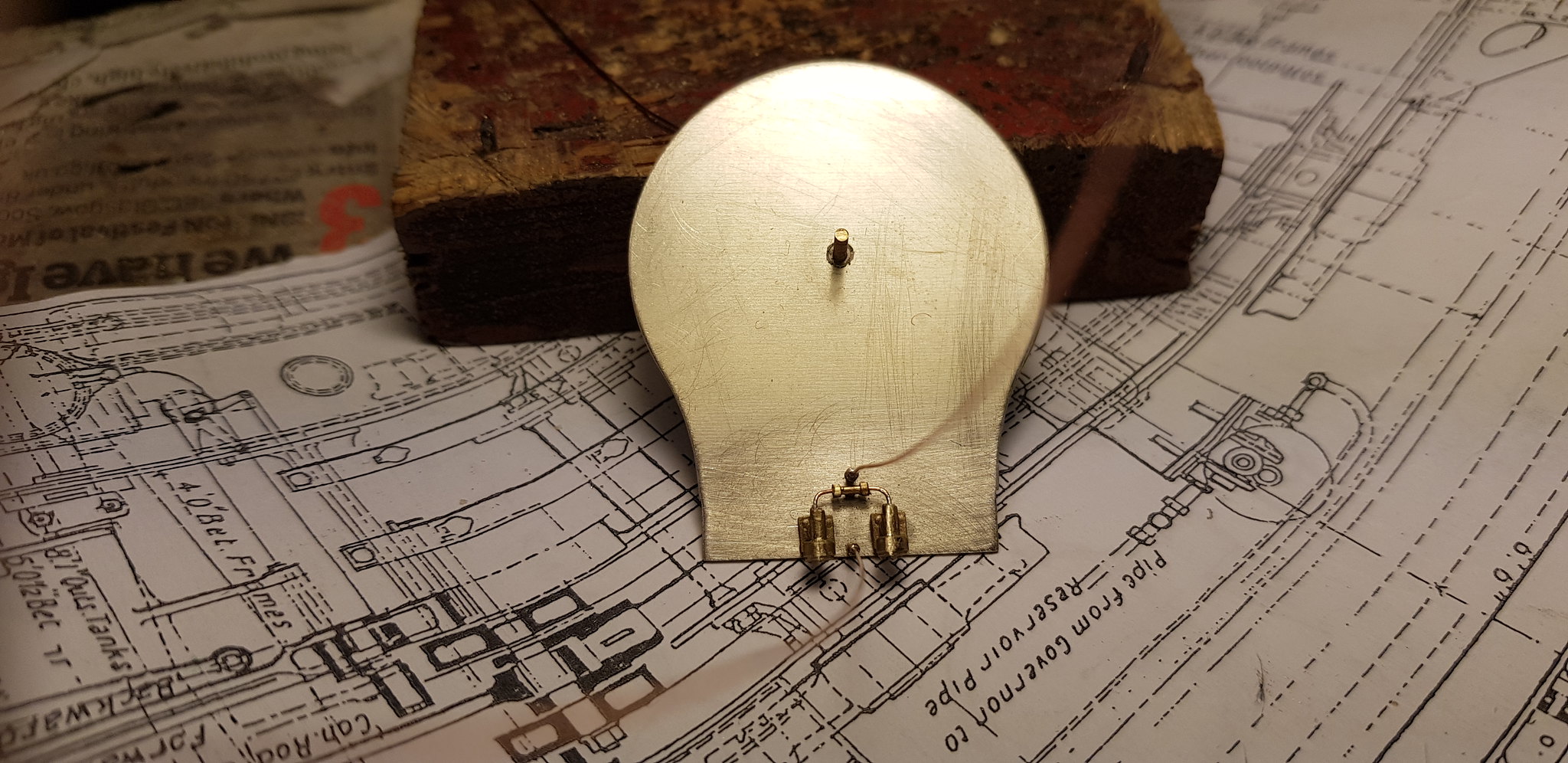

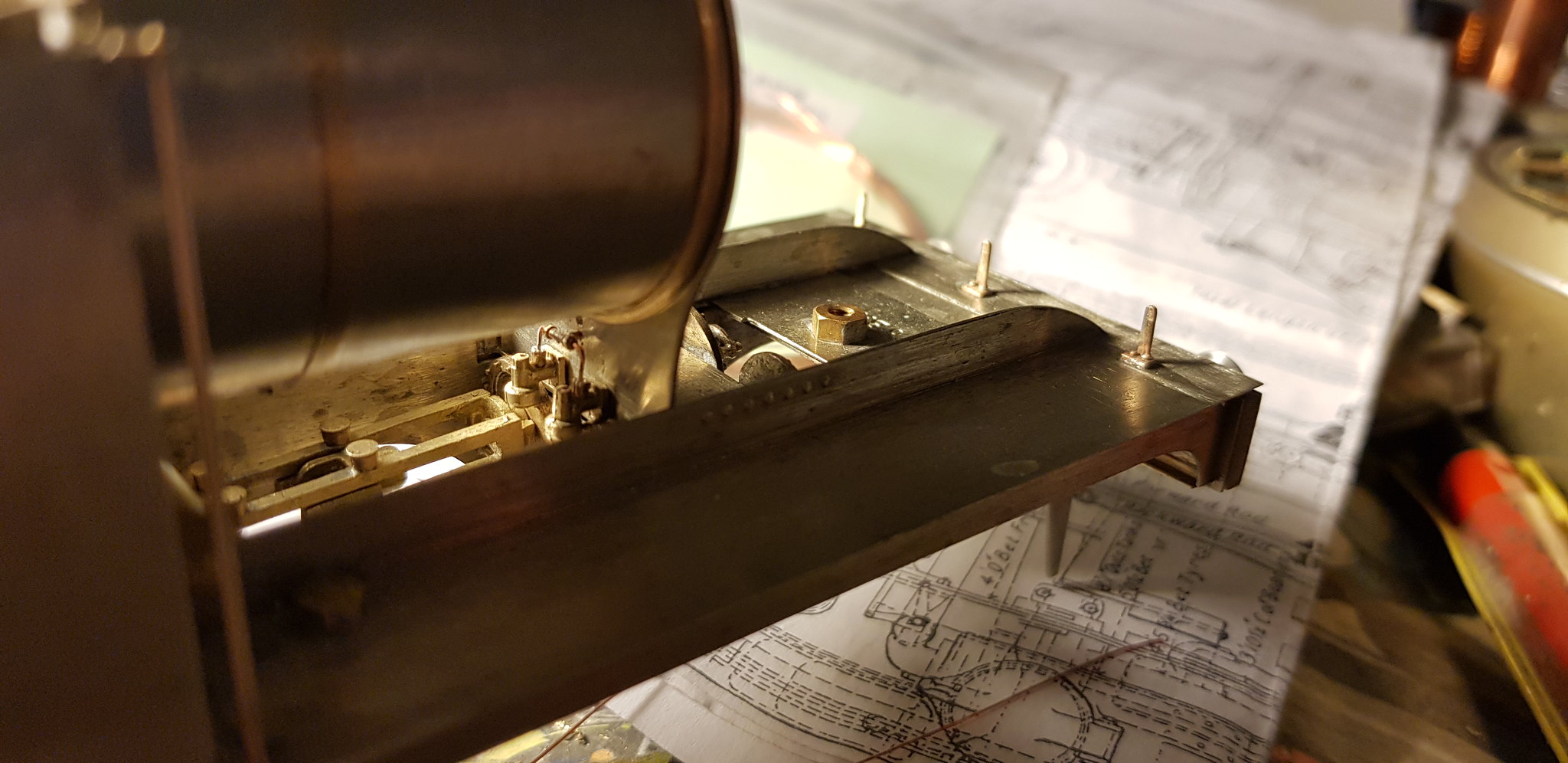

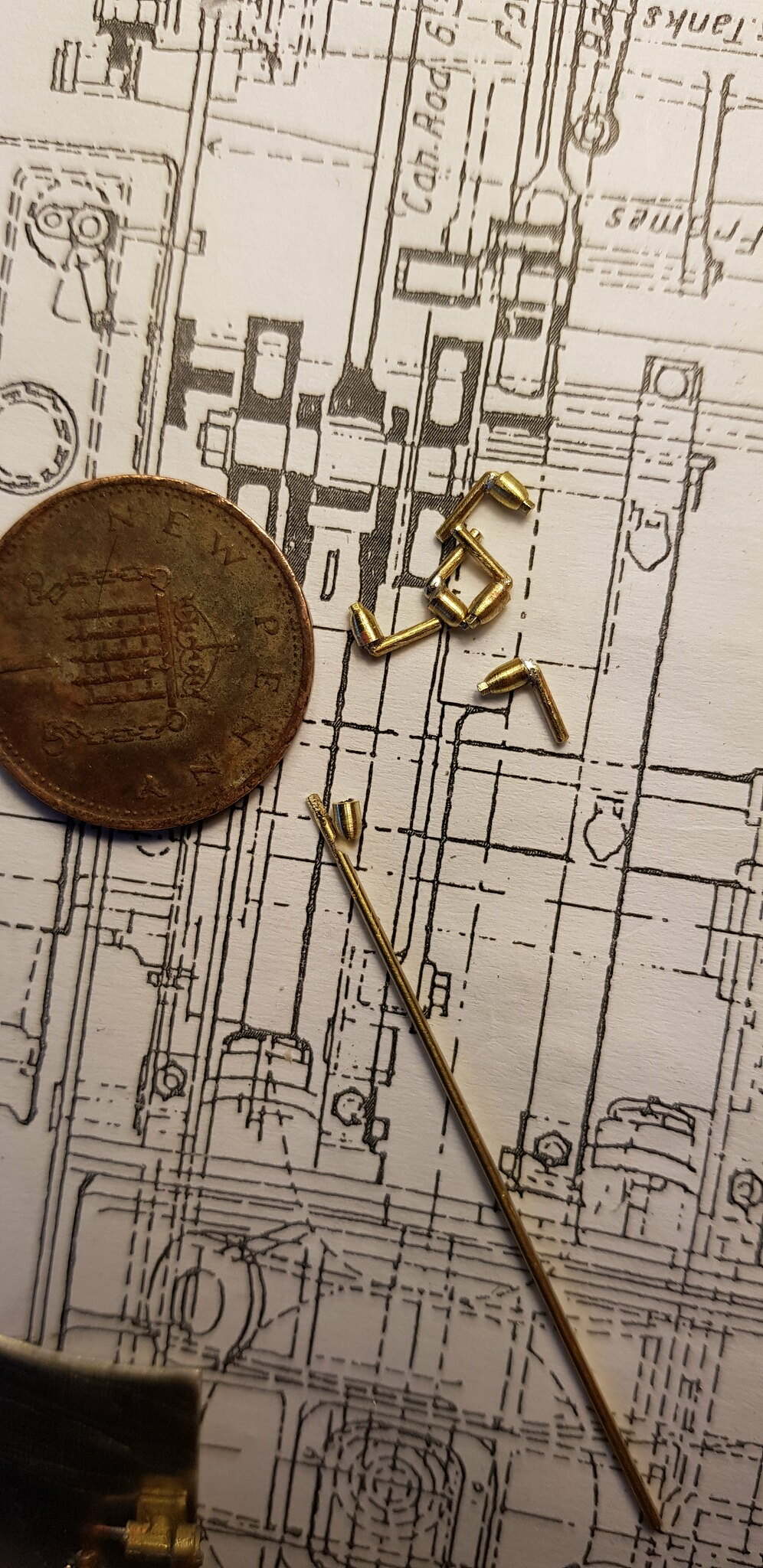

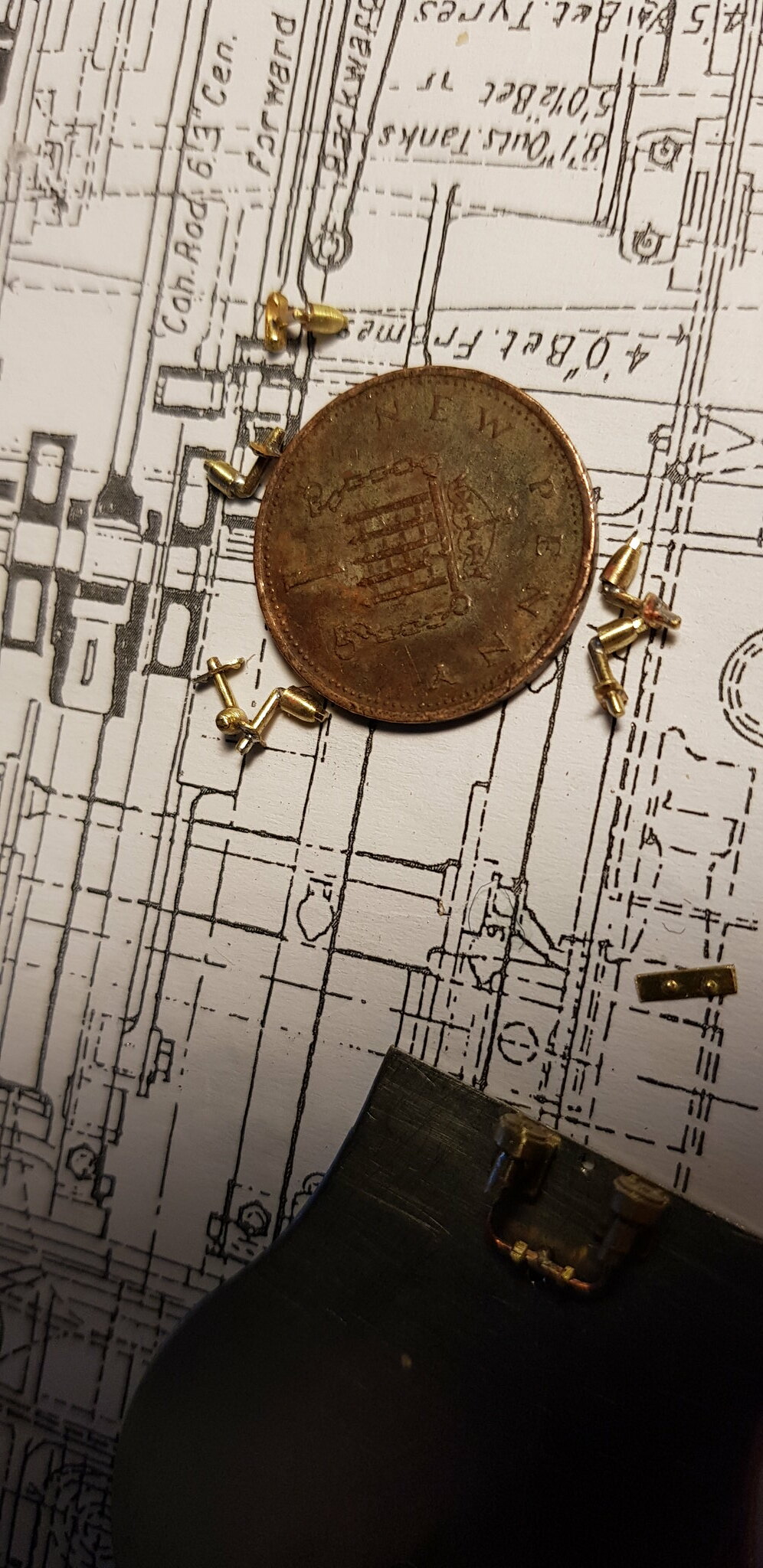

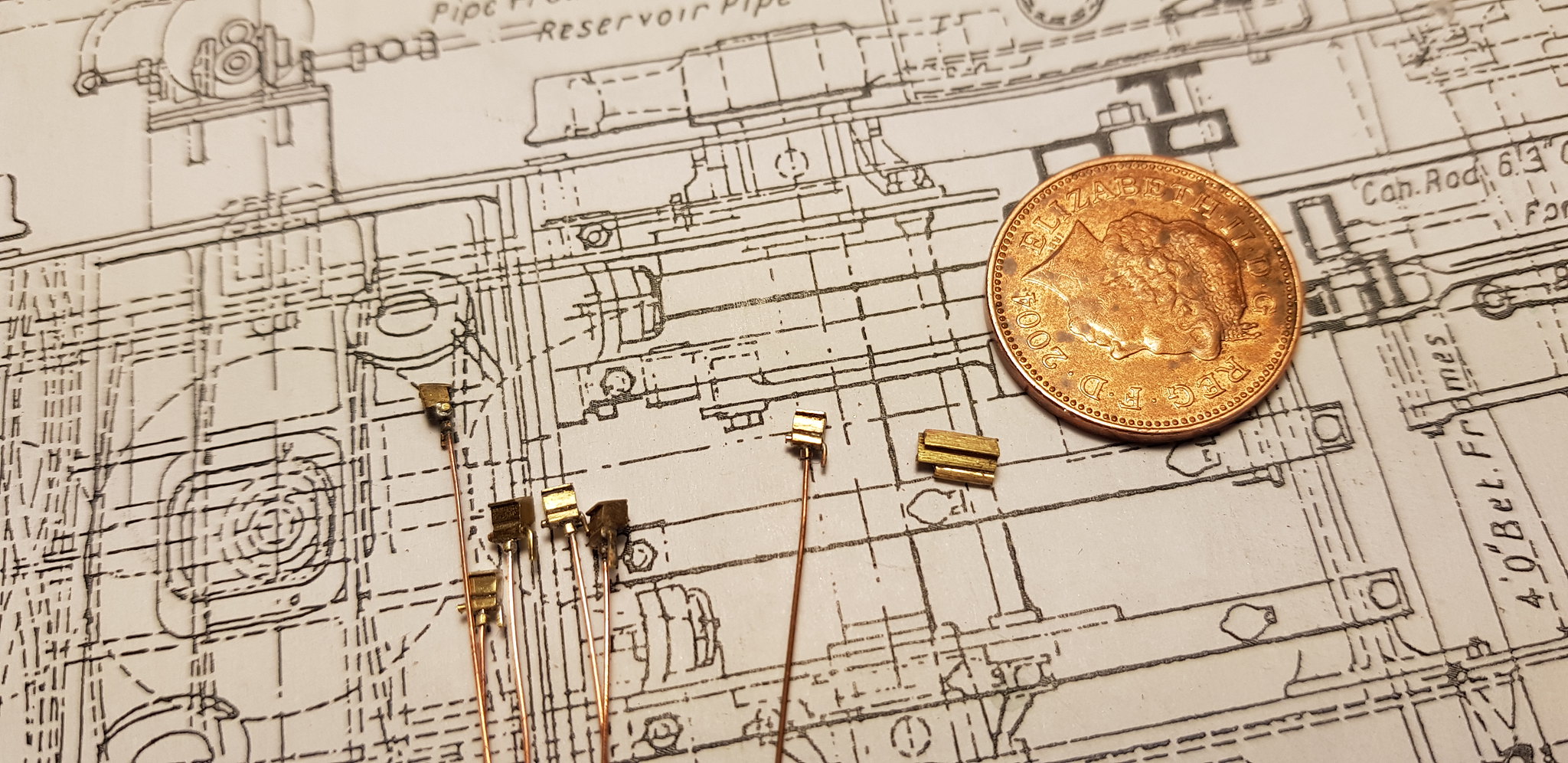

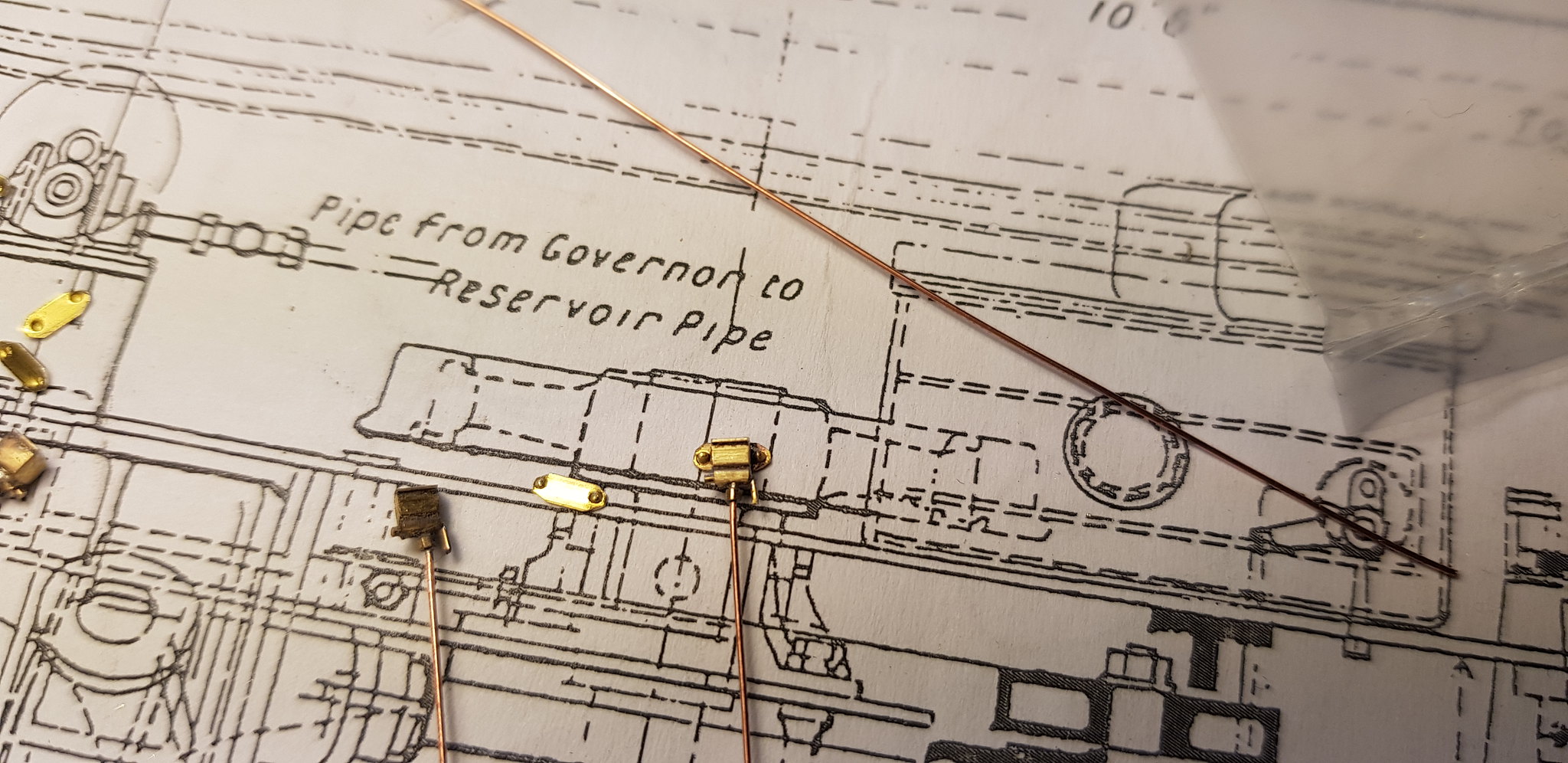

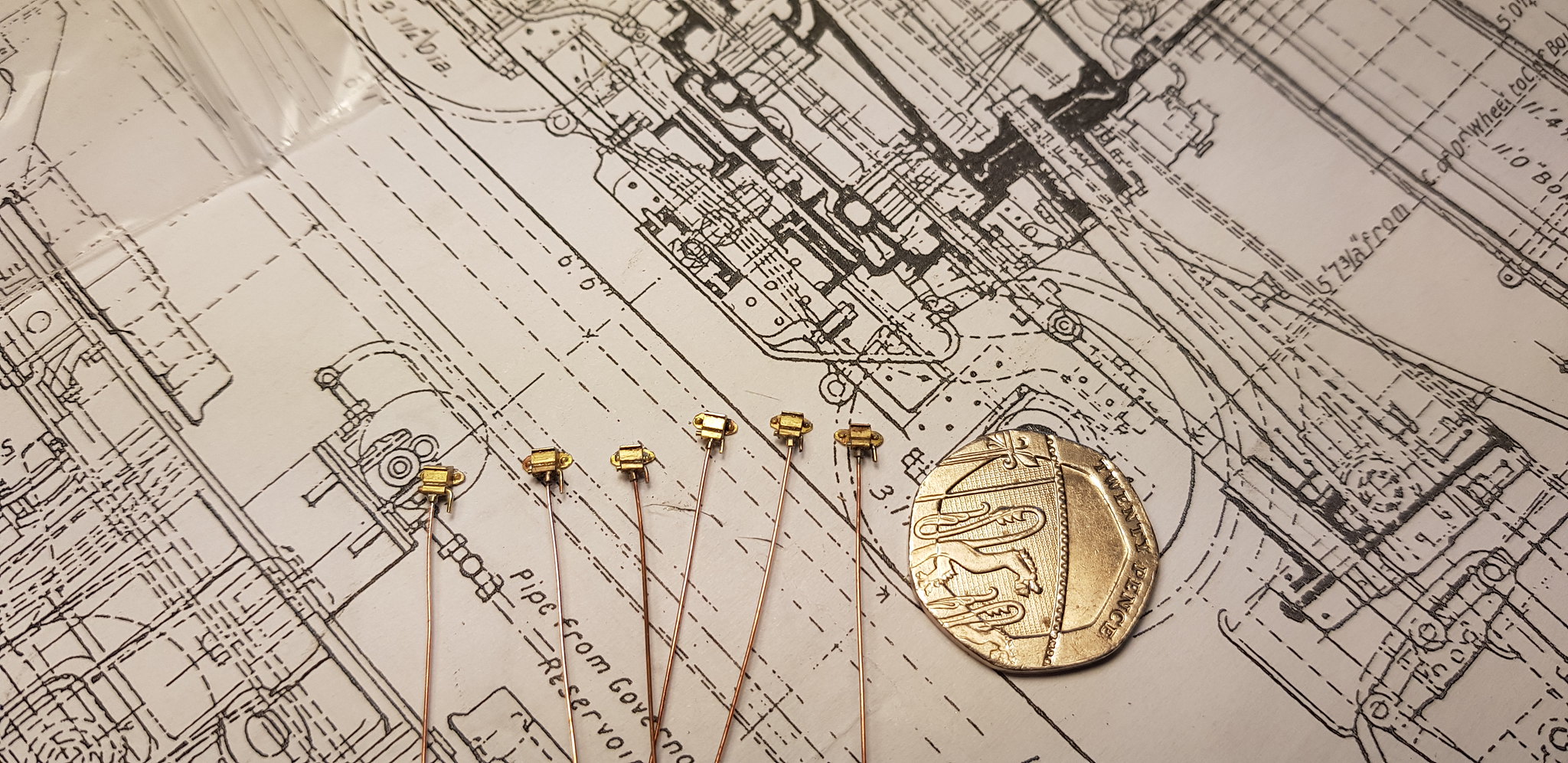

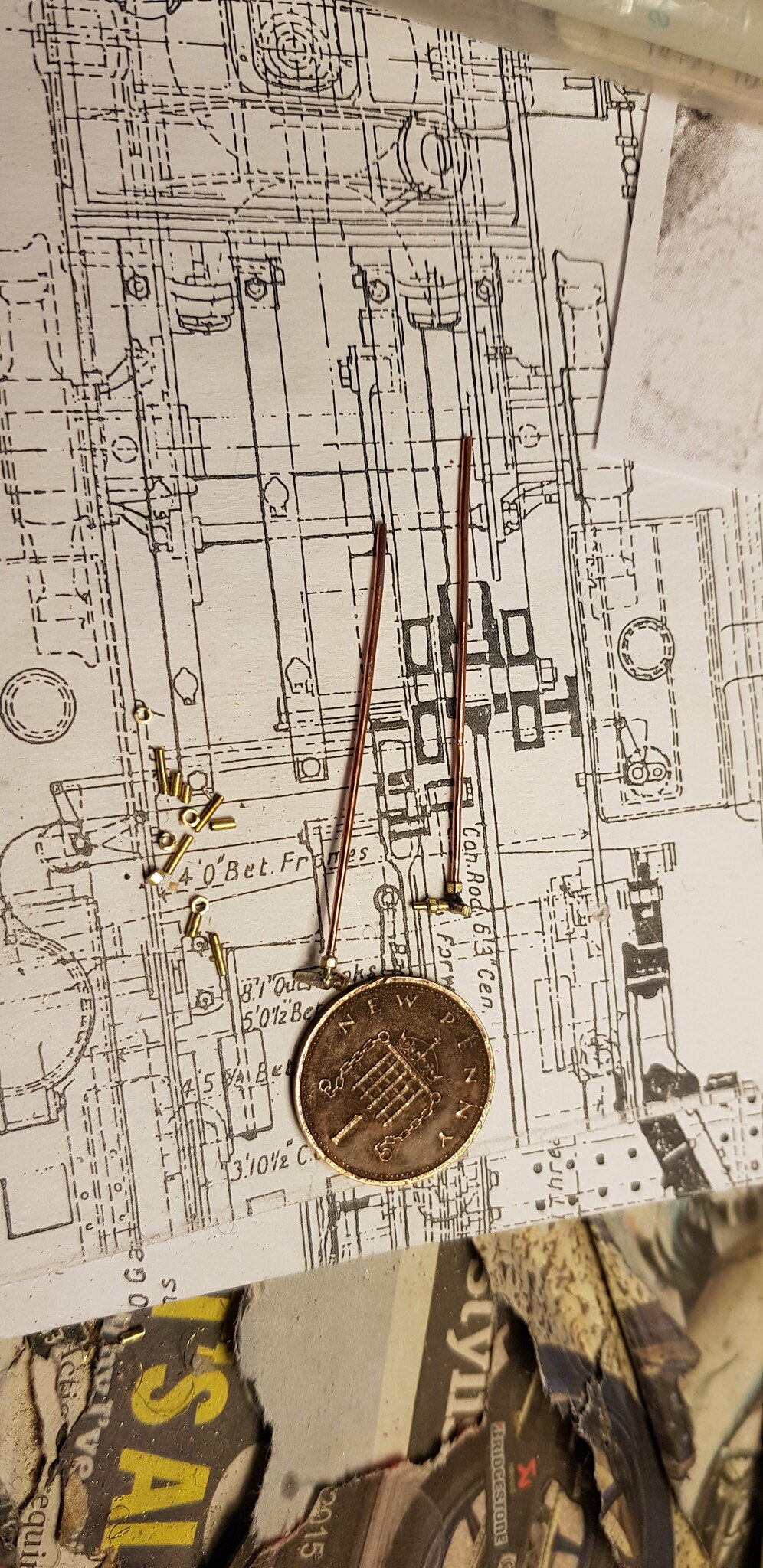

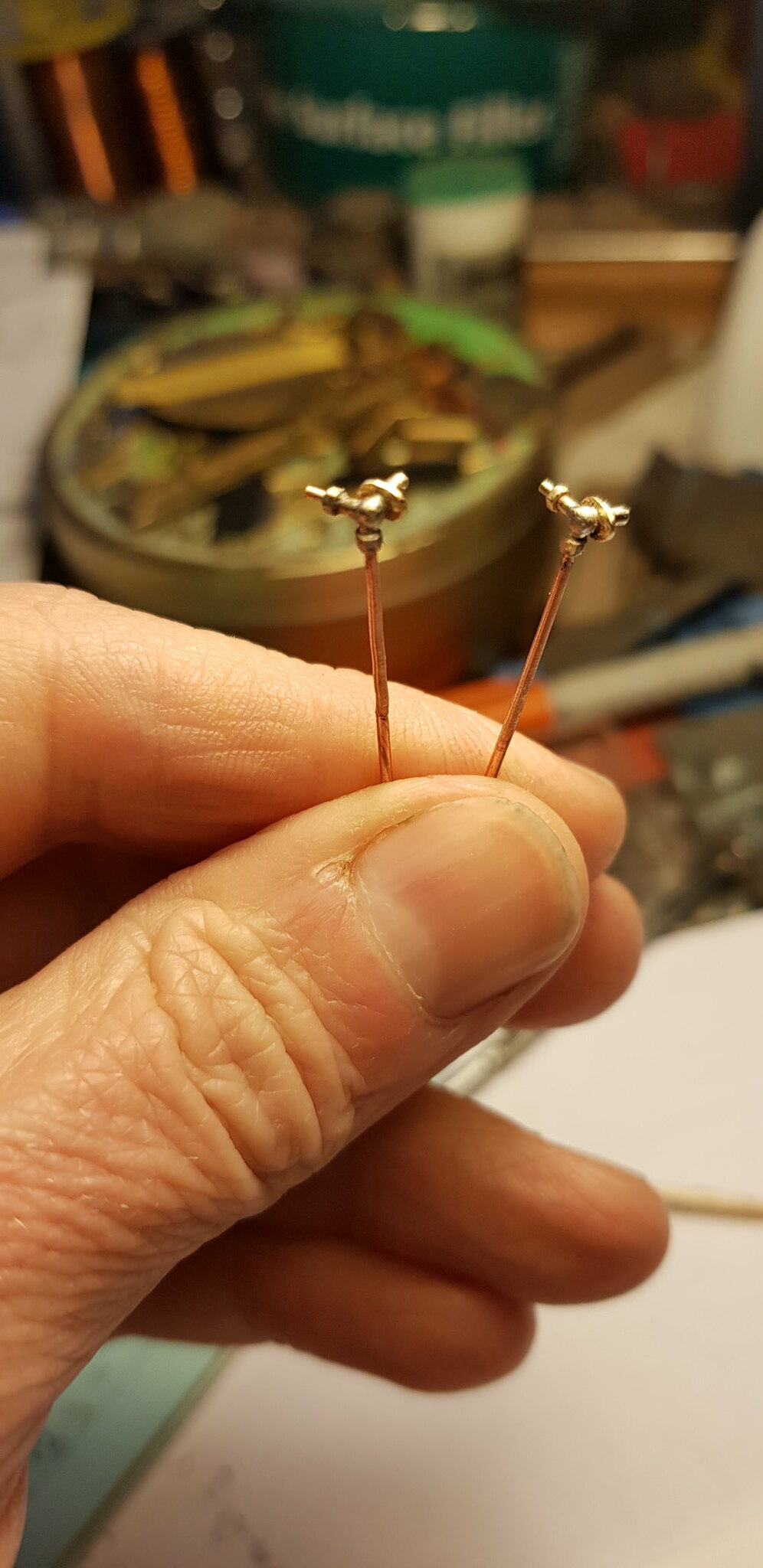

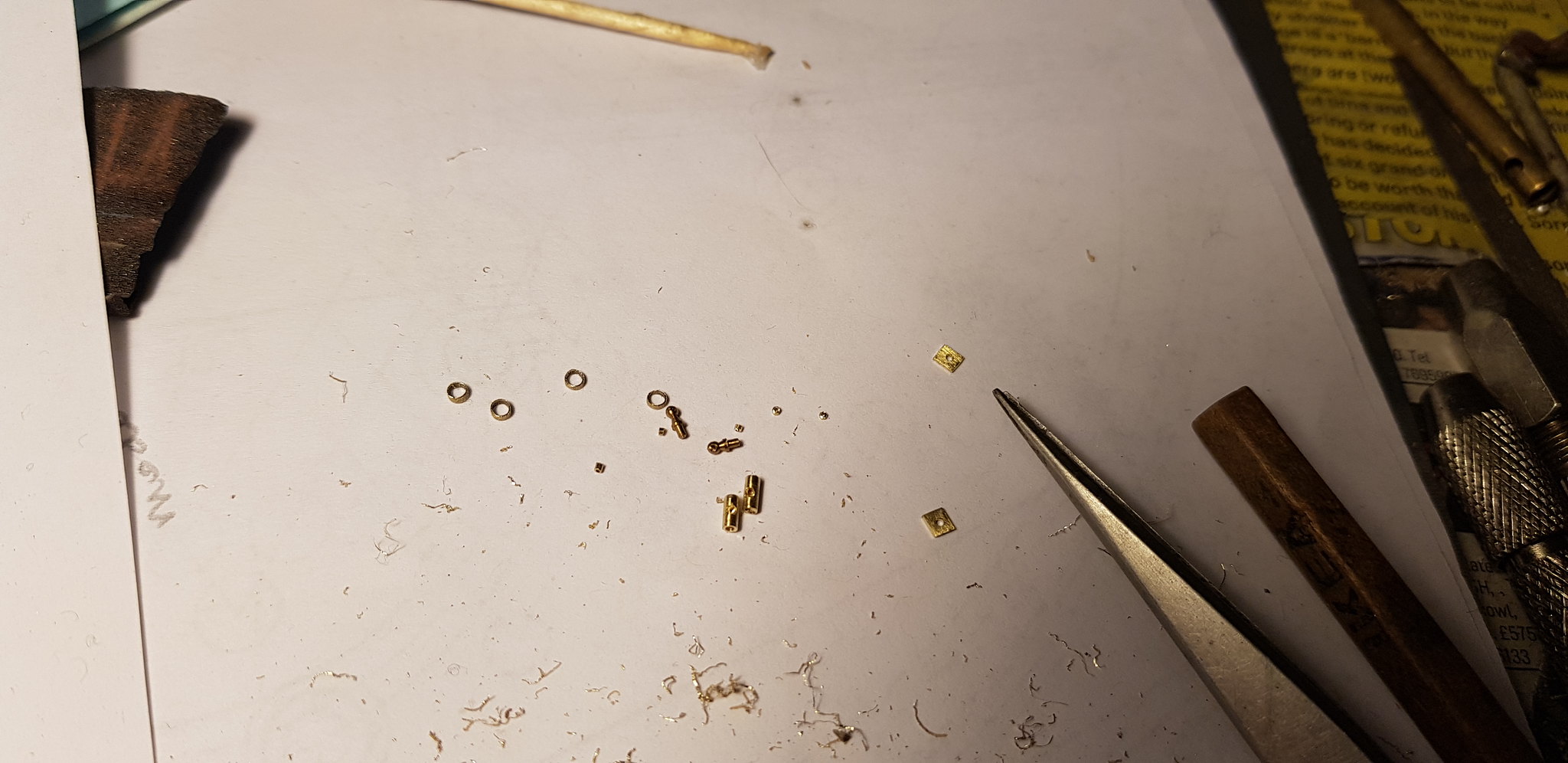

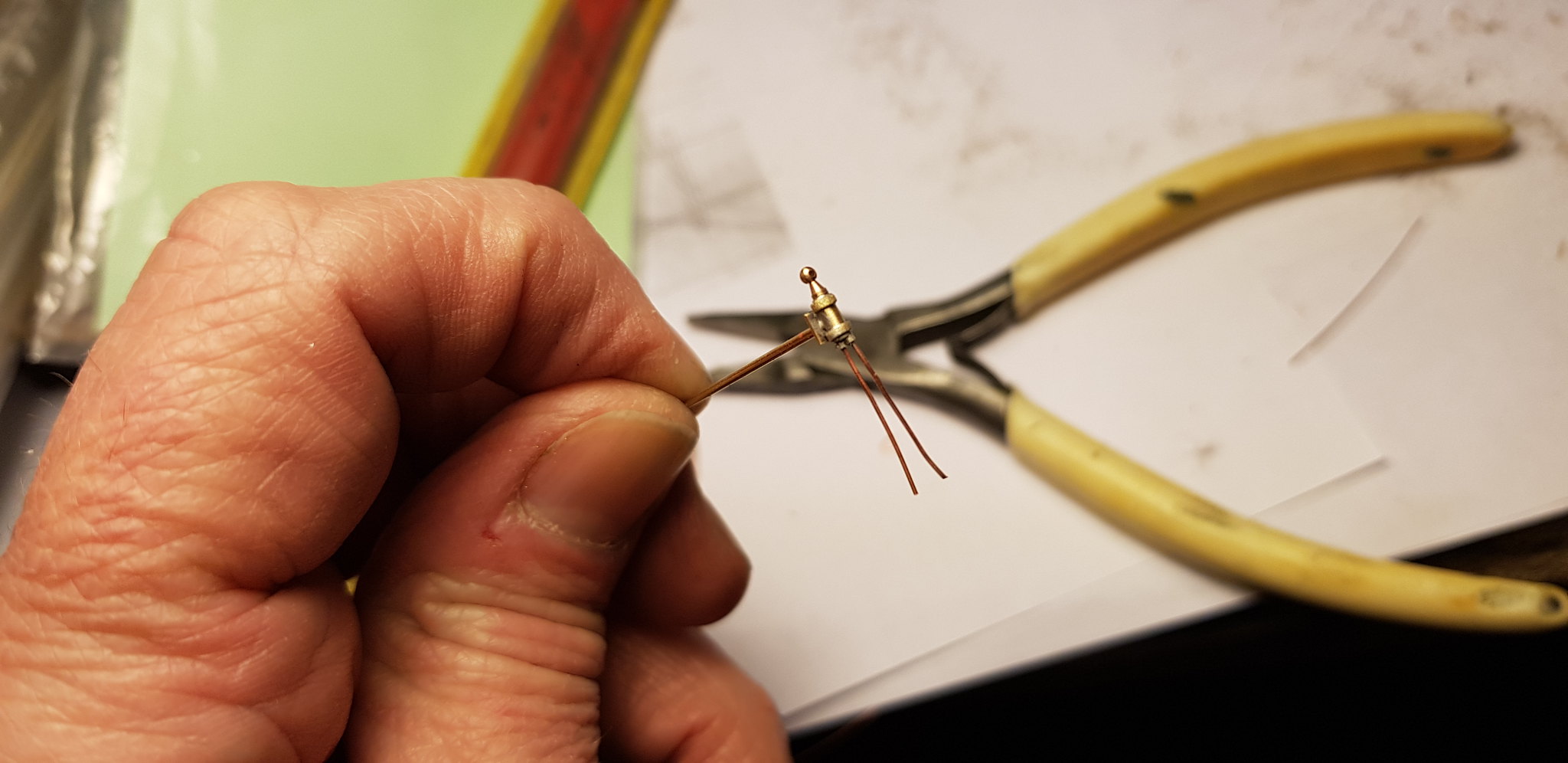

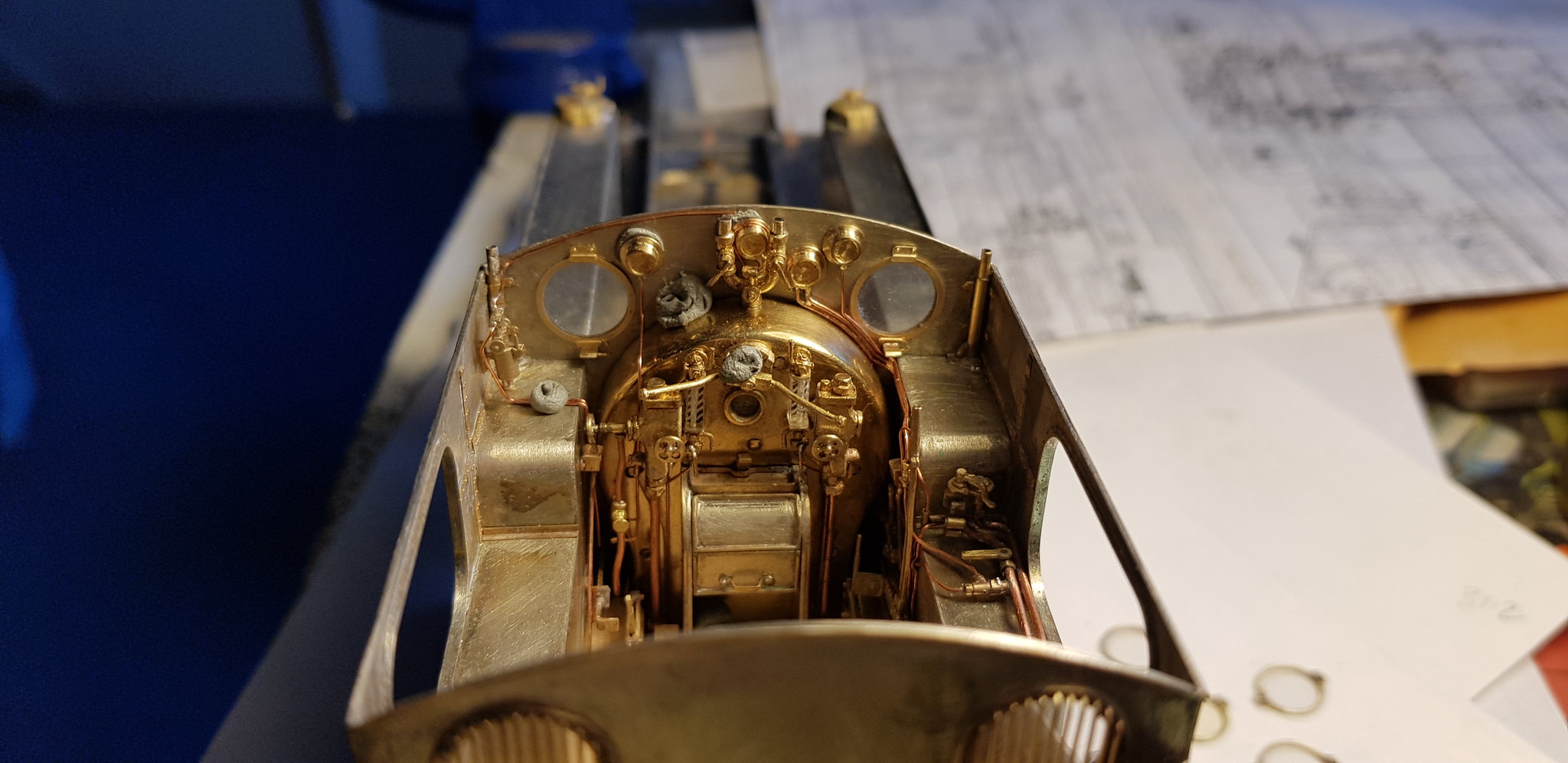

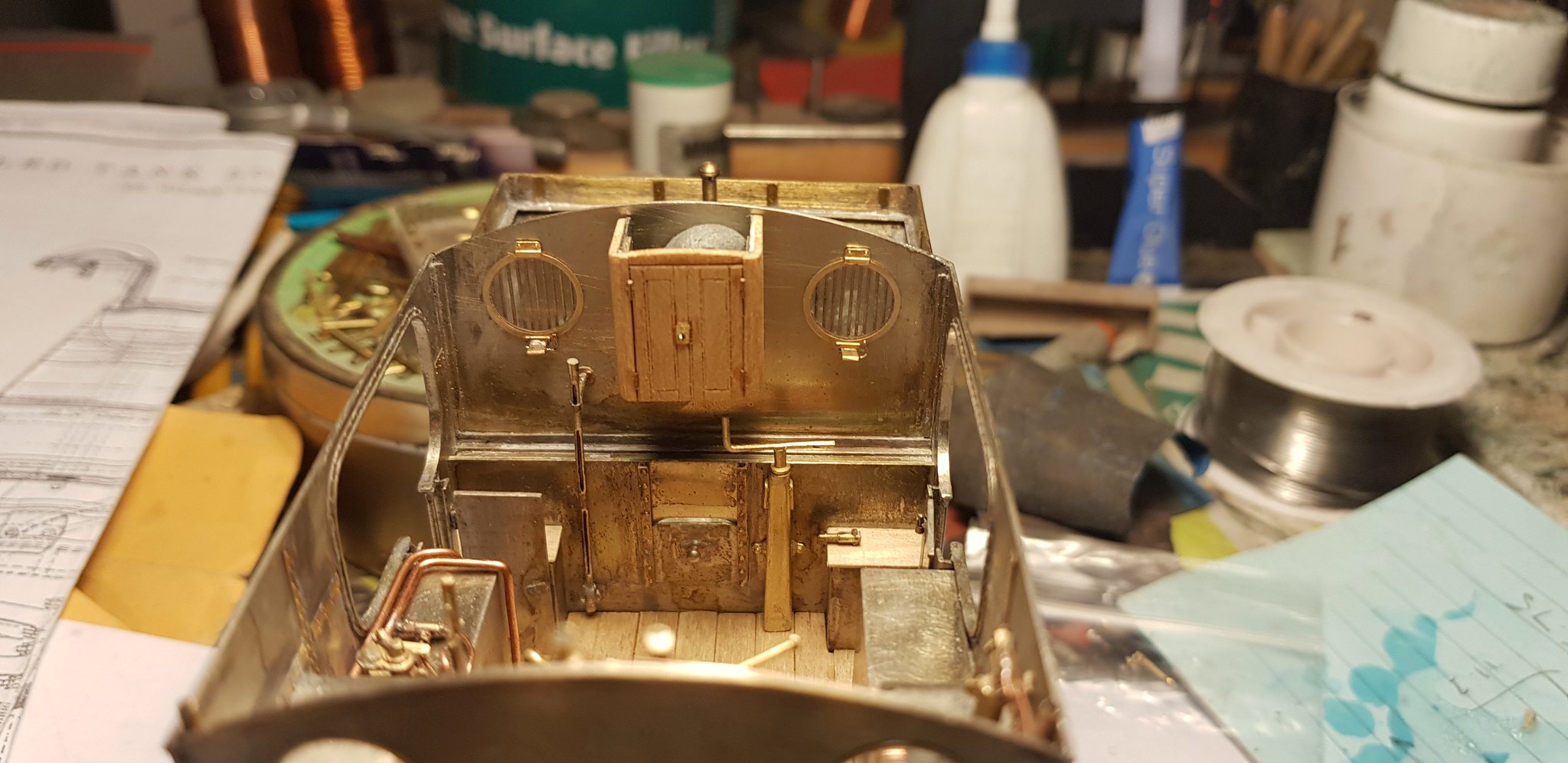

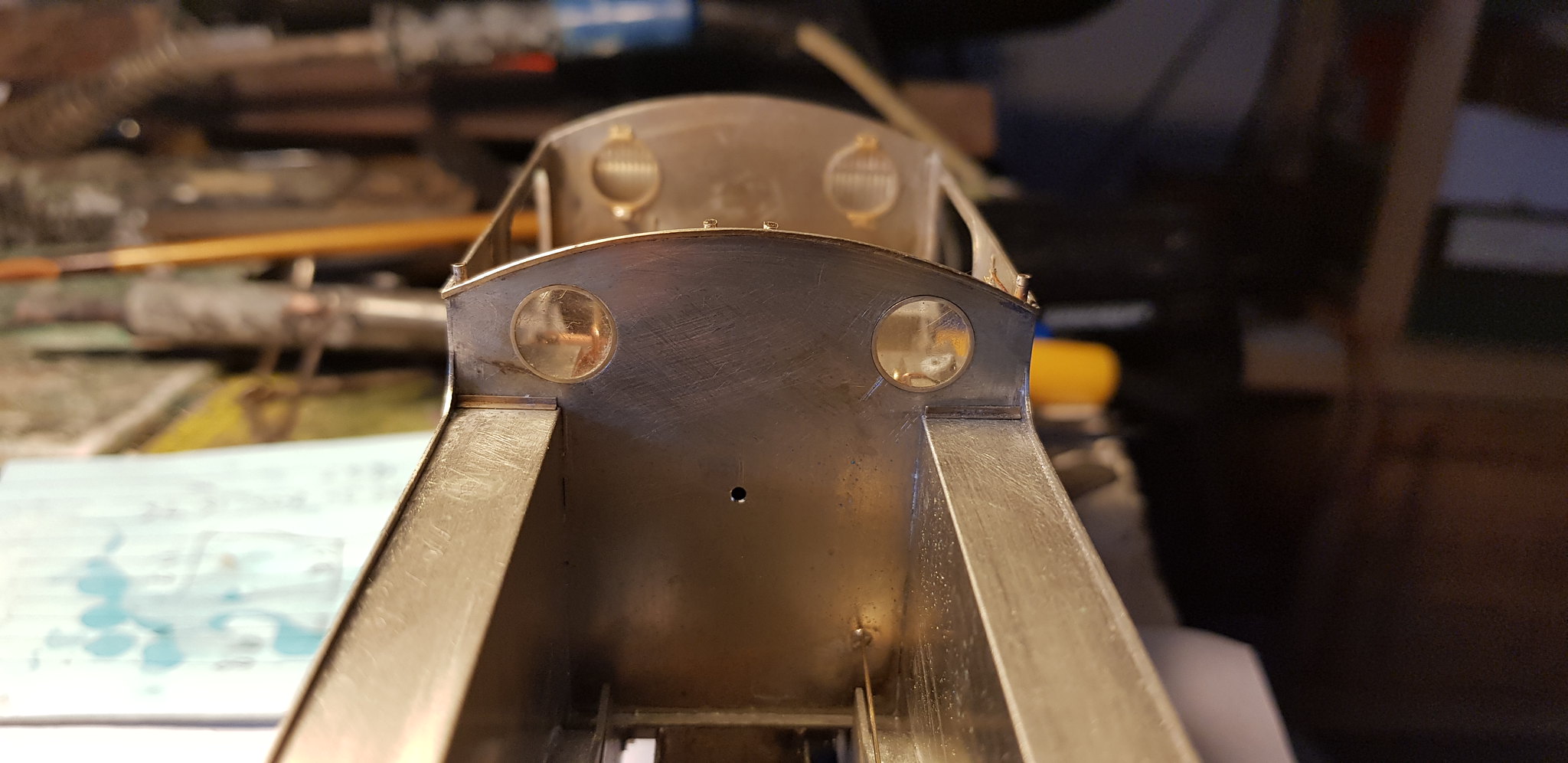

...Thanks for the encouraging words guys. I have made some brass fittings to accommodate the copper pipework on the cylinder block/smokebox rear. I think the bigger brass castings are anti-vacuum valves and the long copper pipes are the high pressure oil/steam mix for the cylinders and valve chests. The pipes originate from the atomiser in the cab.

Tomorrow will be a nice day so no modelling, I'm off out on me motorcycle and the Ws can wait.......

Tomorrow will be a nice day so no modelling, I'm off out on me motorcycle and the Ws can wait.......

!

!