P A D

Western Thunderer

Hi Mick,

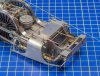

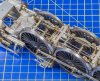

It needed doing and the slight alteration to the back head is neither here nor there. How will the roof be secured? On the A4 I've added some strips of brass to the top edges of the cab sides above the windows, to increase the surface area for epoxying after painting. Will you do something similar or do you have a cunning plan?

Looking at the fit of your raised cab floors pedestals shows how bad mine are on the A4. I had to do a fair bit of filing to get them into the recess in the floor and took metal of the top edges in the process. I will have to fill mine as yours look so much better.

Cheers,

Peter

It needed doing and the slight alteration to the back head is neither here nor there. How will the roof be secured? On the A4 I've added some strips of brass to the top edges of the cab sides above the windows, to increase the surface area for epoxying after painting. Will you do something similar or do you have a cunning plan?

Looking at the fit of your raised cab floors pedestals shows how bad mine are on the A4. I had to do a fair bit of filing to get them into the recess in the floor and took metal of the top edges in the process. I will have to fill mine as yours look so much better.

Cheers,

Peter

it's just build, photo, publish, build, photo..... y'all know the drill.

it's just build, photo, publish, build, photo..... y'all know the drill.