Focalplane

Western Thunderer

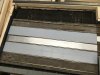

The rails are going back onto the T3 traverser deck:

The running line is glued down and the feed wires attached. Now the two offset lines (unpowered) are to be fixed in place. Plenty of CA glue and the Tufnol surface has been sanded to provide better adhesion than before. As mentioned earlier, some weights will be bolted on the underside of the deck to give greater stability.

Today I obtained some thin aluminium sheeting to see if it will look OK and can take punched rivets. This probably means no chequered pattern after all, those sheets are too expensive!

The running line is glued down and the feed wires attached. Now the two offset lines (unpowered) are to be fixed in place. Plenty of CA glue and the Tufnol surface has been sanded to provide better adhesion than before. As mentioned earlier, some weights will be bolted on the underside of the deck to give greater stability.

Today I obtained some thin aluminium sheeting to see if it will look OK and can take punched rivets. This probably means no chequered pattern after all, those sheets are too expensive!