Was the prototype perhaps dual purpose convertible rather than either/or?

The Metroplolitan Wagon Co built a couple of wagons for the M&SWJR in 1896, titling their drawing 'Combined Timber and Goods Wagon' and I don't suppose the concept was then unique.

On these vehicles, the intention appeared to be to run with bolster in, ends down, and sides up in 'Timber' mode, but with bolster out and ends up in 'Goods' mode.

The 2 plank sides were conventionally hinged along the bottom to drop down and out, the ends likewise but hinged to drop down and in.

In 'Goods' mode, sides and ends mutually supported each other with conventional clasps in the top corners.

In 'Timber' mode, sides were held upright by metal struts which were hinged on the headstocks and swung out to act as supports.

In later years, the vehicles were re-classified simply as goods wagons so at the very least the ends may have been fixed with conventional wooden stanchions.

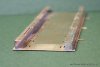

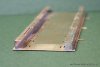

Photo shows a part built 7mm model from the top shelf, showing the end/ side arrangement in 'Timber' mode, although not yet the struts etc.

I will keep looking in for replies.

I will keep looking in for replies.