Thanks, for the comments, I've also heard the NGG16 can be a bit loose on their feet. I read somewhere that WHR have tracked down some of the problems to the original sanding gear, Wales being a touch damper than South Africa which leads to poor sand application, I think some of the engines have been back in to have steam sanding fitted recently, certainly one for a trail.

One thing that does effect traction on the rear engine is the lack of water on one batch, 143 is from the batch (137-143) with enlarged coal space and no rear water, obviously the coal does not fill all the water space so that void is empty and reduces the weight on the rear engine, enough to make it slippery. If you watch Utube vids you'll often see 143 rear engine slipping.

Didn't know about the Puffing Billy exploits, makes sense though, these things are often shrouded in politics, shame as I think it'll be a crowd pleaser, much like the WHR one's have been, there's nearly as much interest in them I hear, as there is in the traditional Welsh stock.

Your right about the smoke box support platework in that there's no hole for the pre-war versions, well not all of them, I've seen one or two photos with engines that have the swept back pipes and the hole in there as well. The problem is, there seems to be a lot of local amendments so one rule does not fit all.

Later engines have the 'Gorilla pipes' but are often covered.

Source - Wikipedia.

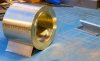

The shape of these varies but this looks the simplest and most attractive, being a simple arc shape. Note one line of wrapper rivets only and much higher up and in line with the hand rail support.

The front bunkers do vary, I like the riveted ones, but I also like the super sized flat topped ones, apparently there's three sizes, original riveted ones, then flat top ones the same size and finally flat top but enlarged for the later batches, I think the height might be the only difference.

The rear end by the smoke box differs between riveted and welded.

Riveted

Source - Flickr

Welded

Source -Flickr

By far the easiest shape is the riveted one and the more interesting I'd say, detail wise, but it lacks the bulk of the welded style for me. I don't think that's a standard water filler on the green one (143) either.

The other issue is drawings, mine are for the later series with enlarged tanks (137-143 / 149-156) and I suspect the riveted style is very close to if not identical to the NGG13 class which I need to get in due course, I do have the G15 class but that's not applicable here.

There's a good couple of pages on RMWeb which has some nice shots and details of one of the routes and track plans, as well as overall station scenes to give you a good flavour of the scene.

SOUTH AFRICAN TWO FOOT GAUGE RAILWAYS - Narrow Gauge Modelling & Prototype

But I recently discovered this site which is excellent for all things SAR and mostly steam, some cracking photos and descriptions, you could loose days reading all this, and I have! But the pages we're interested in are here.

System 3 - Soul of A Railway

The first eight pages detail the 2 foot systems, the rest of the pages on the site are devoted to cape gauge.

But if your specifically looking for Garratts then then you need pages 8, 9, 10 the Caledon line in this section

System 1 - Soul of A Railway

I also picked up drawings for GO, GMA, GMAM, GEA, 15F, 15A, 15AR, NG15 to add to the 25NC and NGG16 I already had, but need to go back for a few others in due course.

Finally, the one thing that appeals about NGG16's is their colour, there isn't a wrong colour to paint them in, and they all look great.

I was going to try and get up there today but the weather forecast is rubbish and I don't fancy all that driving in crap weather, it's a long way there and back in a day, but I will visit shortly.

- Enjoy!