P A D

Western Thunderer

Thanks Duncan and Larry for the photos.

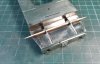

Leaving the rods for now I first rolled and soldered up the smokebox. There are two rings on the etch, one plain and one with rivet detail that needs punching. I'm not sure if Mike Edge intended the plain ring to go in the rear of the smokebox, but I decided to fit it inside and flush with the front edge. The riveted ring had the edge rounded before punching the rivets and overlaying onto the other ring. At the rear I added a strip of waste fret to locate the boiler.

This front view shows the strip of waste fret used to beef up the seam.

I made a copy of the boiler template and then marked the centre line and position of the top feed, dome and wash out plugs. Here the centre lind is marked with the other details still to be added. It was then cut out and pasted to 10 thou nickel silver sheet, where the centre line and other details were transferred to the metal before cutting.

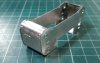

The boiler was cut out using a mixture of scrawker and piercing saw and finished off with the file. Before rolling, I scribed the centre line to represent the cladding seam and punched some rivets to represent the fixing screws. Although I agree with Adrian that softer grade NS would be easier to roll, I didn't have any problems with it being half hard and more springy. However, if took a bit of faffing to get the taper correct using parallel rolling bars. Here it is push fit onto the smokebox. It won't be soldered until later in the build in case any adjustments need to be made to get it to sit right.

Looks good so far.

A quick trial with a dome from the spares box looks promising.

One issue I did encounter was that the circumference of the boiler was about a mm too short. I could have made another one but decided a quicker option was to add a filling piece. A straight length of waste fret about 3mm wide of the right thickness was used for this. First I clamped it lengthways in the vice to hold it still and vertical. The was boiler was then placed over the strip and held tight against it either side and tack soldered each end. When I was happy that is was aligned correctly, the whole seam was soldered either side of the strip. I then removed the excess metal on the outside of the seam with a cutting disc and tidied up with files and emery paper. Here's a view of the seam showing the infill.

With the boiler done for now, I finished off the other coupling rod. I wasn't happy with the filed down nut used to represent the fixing for the joint on the completed rod, so I removed it and knocked up something from a 10 BA cheese head bolt in the lathe.

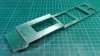

A start has been made on the frames, with the decusping done and the bearing holes prepared. There are parts to make a compensated chassis, but I'm going with my favoured fixed front and rear axles, with the middle one allowed some up and down movement.

I should have the wheels from Slaters tomorrow, so all being well, I may have the chassis rolling by then.

Cheers,

Peter

Leaving the rods for now I first rolled and soldered up the smokebox. There are two rings on the etch, one plain and one with rivet detail that needs punching. I'm not sure if Mike Edge intended the plain ring to go in the rear of the smokebox, but I decided to fit it inside and flush with the front edge. The riveted ring had the edge rounded before punching the rivets and overlaying onto the other ring. At the rear I added a strip of waste fret to locate the boiler.

This front view shows the strip of waste fret used to beef up the seam.

I made a copy of the boiler template and then marked the centre line and position of the top feed, dome and wash out plugs. Here the centre lind is marked with the other details still to be added. It was then cut out and pasted to 10 thou nickel silver sheet, where the centre line and other details were transferred to the metal before cutting.

The boiler was cut out using a mixture of scrawker and piercing saw and finished off with the file. Before rolling, I scribed the centre line to represent the cladding seam and punched some rivets to represent the fixing screws. Although I agree with Adrian that softer grade NS would be easier to roll, I didn't have any problems with it being half hard and more springy. However, if took a bit of faffing to get the taper correct using parallel rolling bars. Here it is push fit onto the smokebox. It won't be soldered until later in the build in case any adjustments need to be made to get it to sit right.

Looks good so far.

A quick trial with a dome from the spares box looks promising.

One issue I did encounter was that the circumference of the boiler was about a mm too short. I could have made another one but decided a quicker option was to add a filling piece. A straight length of waste fret about 3mm wide of the right thickness was used for this. First I clamped it lengthways in the vice to hold it still and vertical. The was boiler was then placed over the strip and held tight against it either side and tack soldered each end. When I was happy that is was aligned correctly, the whole seam was soldered either side of the strip. I then removed the excess metal on the outside of the seam with a cutting disc and tidied up with files and emery paper. Here's a view of the seam showing the infill.

With the boiler done for now, I finished off the other coupling rod. I wasn't happy with the filed down nut used to represent the fixing for the joint on the completed rod, so I removed it and knocked up something from a 10 BA cheese head bolt in the lathe.

A start has been made on the frames, with the decusping done and the bearing holes prepared. There are parts to make a compensated chassis, but I'm going with my favoured fixed front and rear axles, with the middle one allowed some up and down movement.

I should have the wheels from Slaters tomorrow, so all being well, I may have the chassis rolling by then.

Cheers,

Peter

Last edited:

Merry X.

Merry X.