Rob Pulham

Western Thunderer

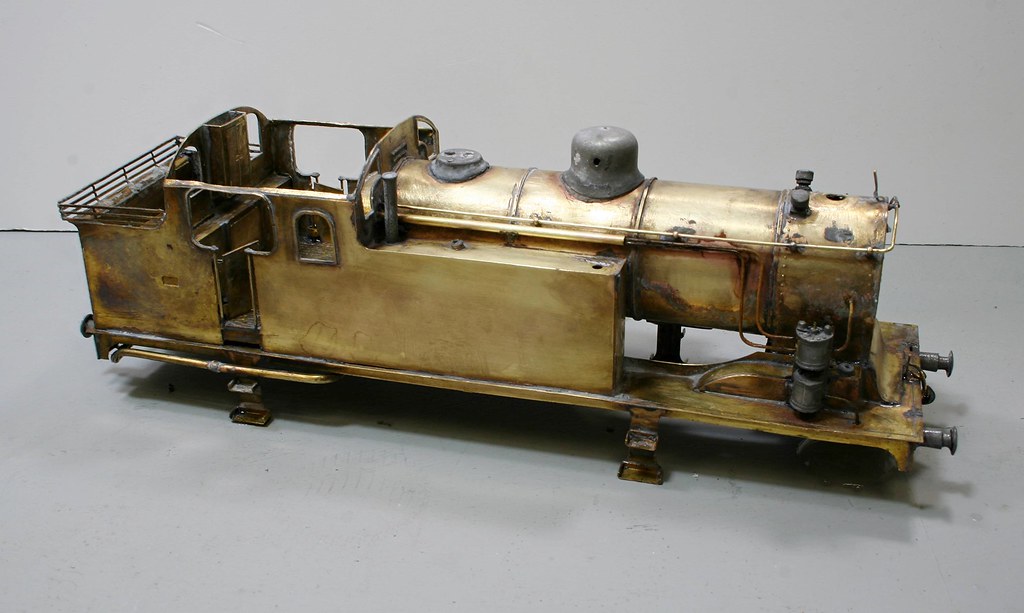

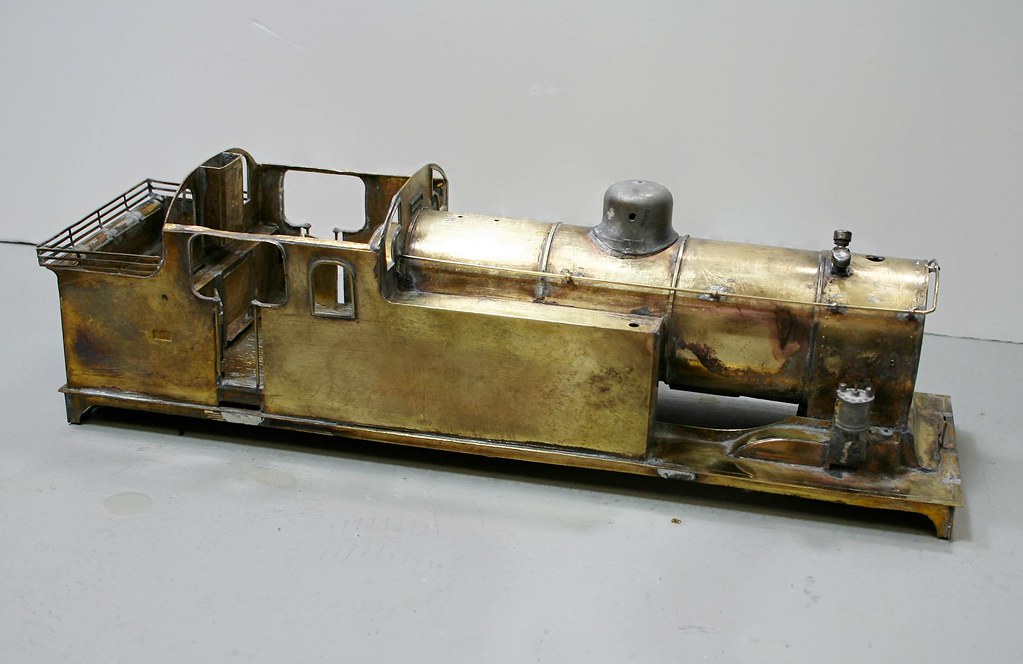

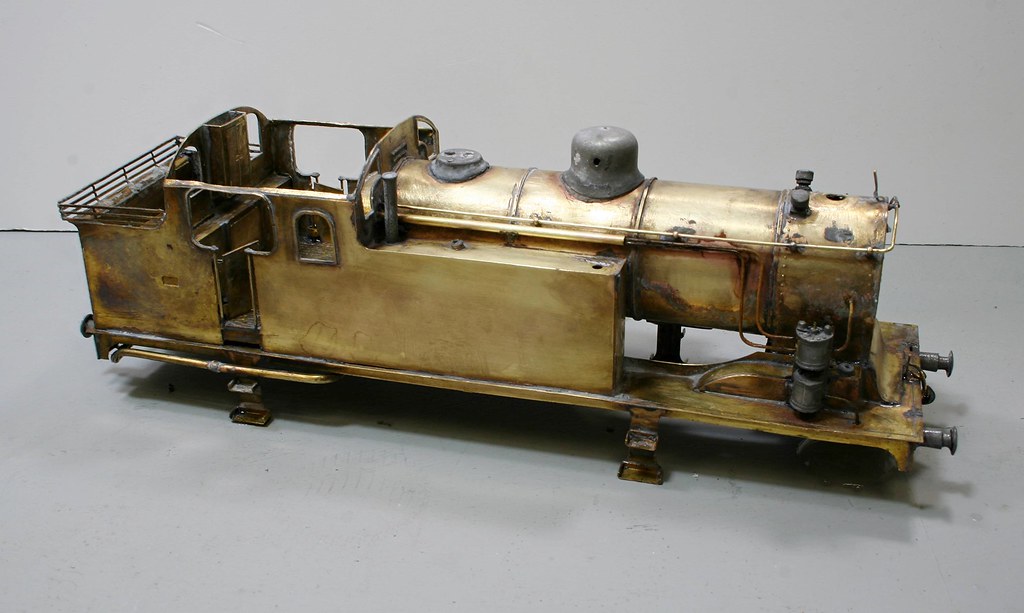

This one is a little different for me, the gent that I am building the J6 for is building a layout based on Hitchen in the late 1950's/early 1960's and N7's were there a plenty. He has several N7/5's but needed at least one N7/3 so he bought one already built via eBAY.

It's lacking some detail and has some that needs to be removed to build his chosen example

The photos below are as it came to me and are copyright of my customer and used here with his permission.

It's new identity is to be 69618 and I am working to a supplied photo of the engine as at 23rd May 1959

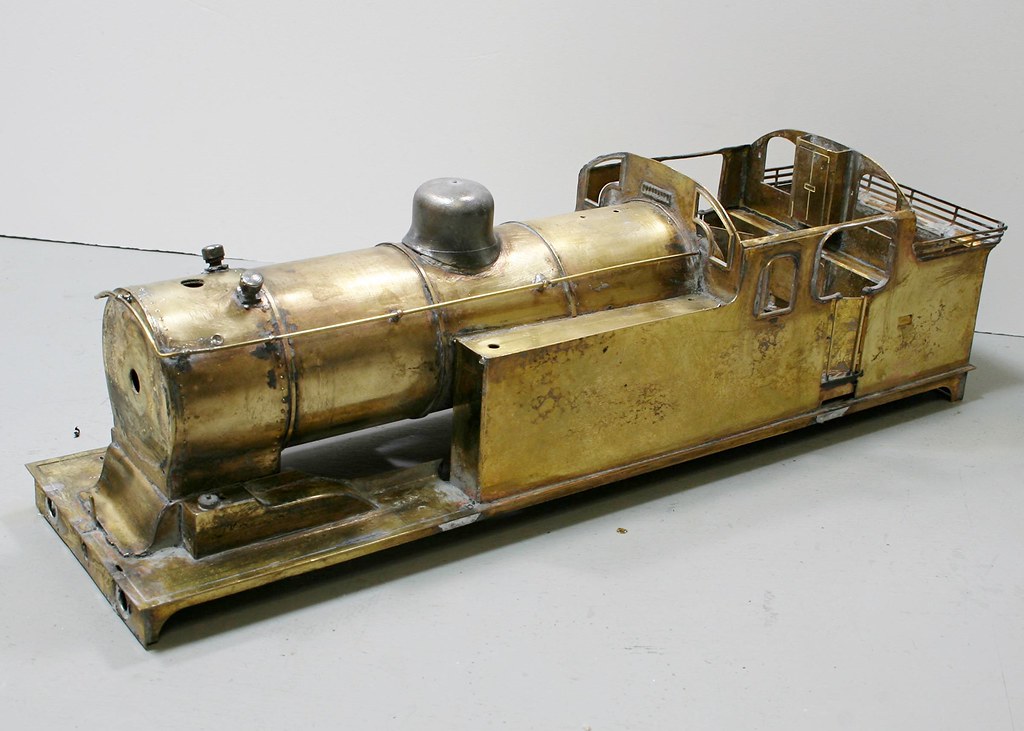

So far this is what I have observed needs to be done:

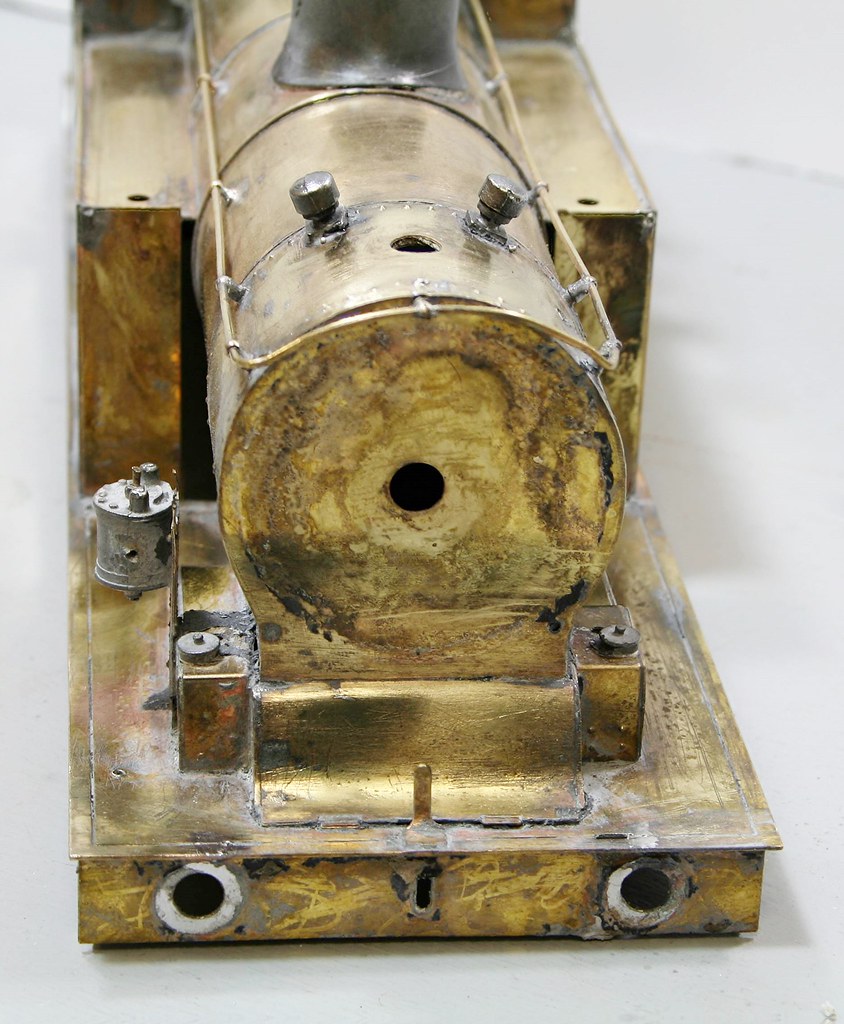

Quite a few bits dropped off and others were coaxed to release their grip followed a scrub with Bar Keepers Friend got it to a point where I was able to use the microflame to remove other parts

It's lacking some detail and has some that needs to be removed to build his chosen example

The photos below are as it came to me and are copyright of my customer and used here with his permission.

It's new identity is to be 69618 and I am working to a supplied photo of the engine as at 23rd May 1959

So far this is what I have observed needs to be done:

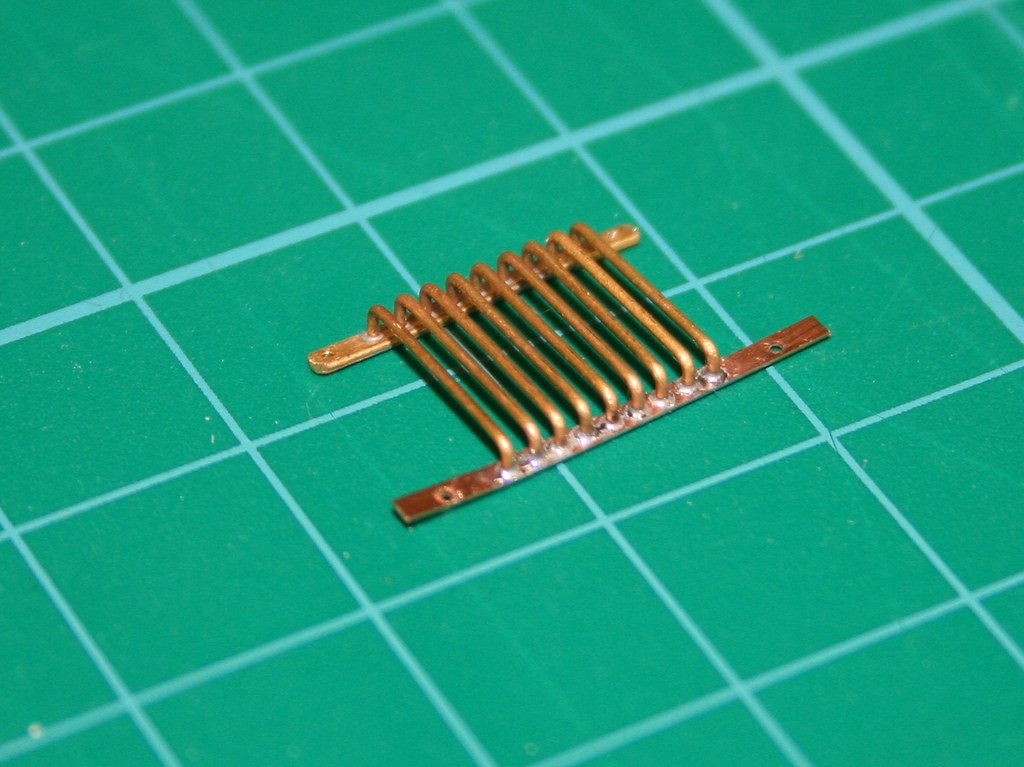

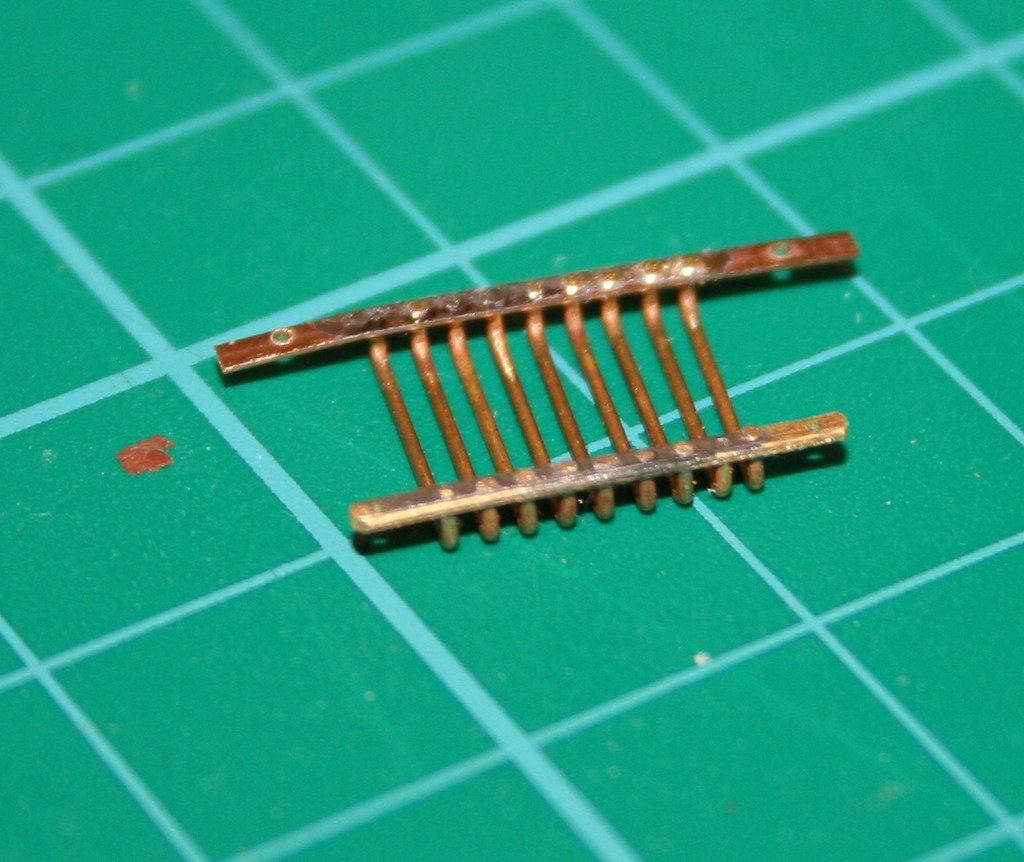

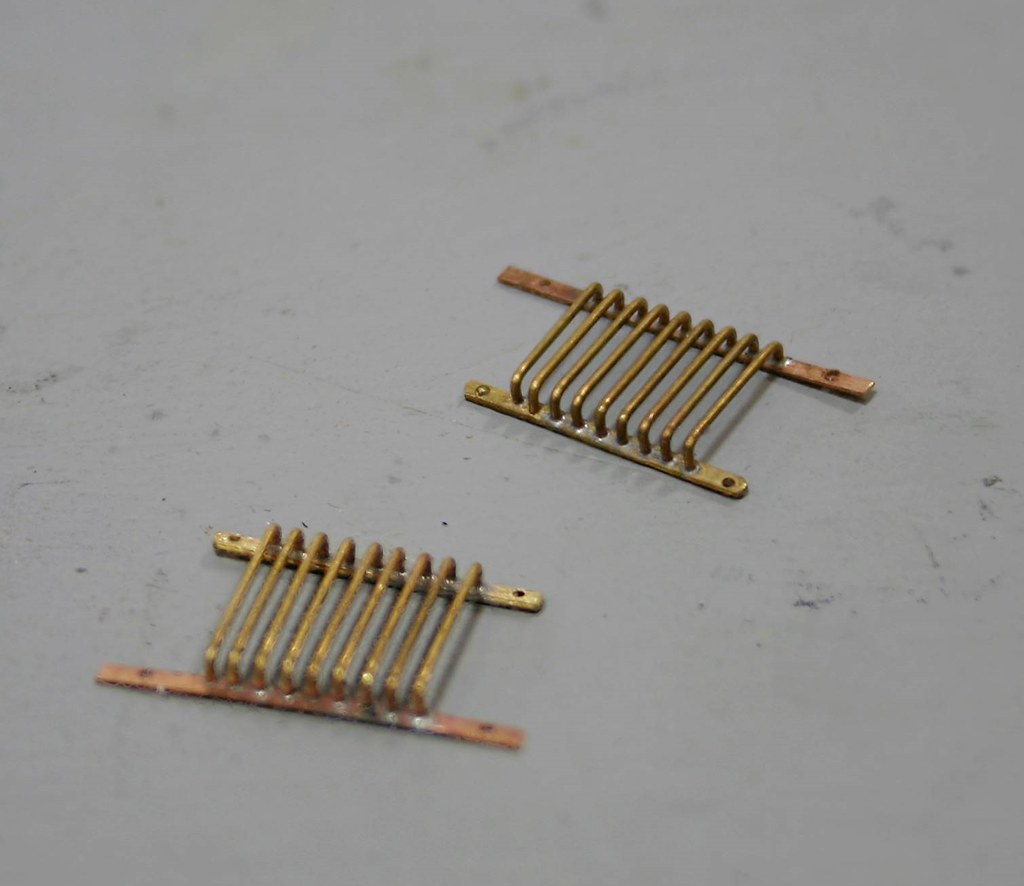

- Window guards to rear cab - half height of windows

- Condensing pipes - remove

- Safety valves, remove base and refit/replace

- Vacuum ejector pipe – boiler to cab

- Remove valve from dome

- Hinge on smoke box door

- Move lamp iron from top of boiler to smokebox door

- Step on Piano front

- Knobs on Piano front

- Oilers under smoke box door – either side

- Steps on tank fronts

- Plate in coal rails

- Glaze cab

- Reversing lever and fittings under boiler to help disguise worm gear from motor

- Move steps from outside of valance to where they should be.

Quite a few bits dropped off and others were coaxed to release their grip followed a scrub with Bar Keepers Friend got it to a point where I was able to use the microflame to remove other parts