Scanlon

Western Thunderer

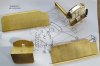

At last I have a 4-6-0 again. The engine steps have been built up and fitted and detail work around the cylinders finished. Yet to fit are the long drain pipes from the cylinder cocks. The major work has centred around the brake gear. The castings for the hangers and brake blocks were very chunky and despite chamfering the back of the blocks I could not get a decent let alone prototypical finish to them. There was nothing for it but to remove the brake blocks in their entirety, they will be replaced with Slaters LMS brake blocks which look very similar to the Southern version. Before each block was removed I drilled out the cast locating pin to ensure the replacement blocks are in the correct orientation. This photo shows the before and after look prior to refitting the pins and tidying up.

So far only the hangers and stretchers have been fitted, Lord Nelson brake gear is a nightmare to build and fit but it has to be done.

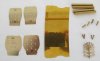

These photos below show the build to date.

A totally unexpected problem arose with the centre driving wheels. When I put the frames under the body this axle locked up completely. Using a spot light I eventually diagnosed the throat plate casting for the front of the firebox was much too wide and rubbing on the back of these wheels. Judicious use of the Dremel and a slitting disc has got rid of that problem and now all wheels revolve and I've got sideplay back on the middle driving axle.

Thanks to Ragstone coming up with the correct battery box, it's the same as fitted to the Britannia pacific's, I've decided to fit the AWS especially as the cabsides have the two holes etched into them for the AWS. Outstanding work on the engine is now centred around completing the brakes, fitting the injectors and installing pick-ups plus building the boiler backplate. The latter will be delayed as I'd like to improve the overall look by incorporating some of the new Hobbyhorse castings.

Once the brakes are finished the frames can then be prepared for spraying and once that has been achieved the valve gear will be built and installed.

Now where is that GWR 2021?

So far only the hangers and stretchers have been fitted, Lord Nelson brake gear is a nightmare to build and fit but it has to be done.

These photos below show the build to date.

A totally unexpected problem arose with the centre driving wheels. When I put the frames under the body this axle locked up completely. Using a spot light I eventually diagnosed the throat plate casting for the front of the firebox was much too wide and rubbing on the back of these wheels. Judicious use of the Dremel and a slitting disc has got rid of that problem and now all wheels revolve and I've got sideplay back on the middle driving axle.

Thanks to Ragstone coming up with the correct battery box, it's the same as fitted to the Britannia pacific's, I've decided to fit the AWS especially as the cabsides have the two holes etched into them for the AWS. Outstanding work on the engine is now centred around completing the brakes, fitting the injectors and installing pick-ups plus building the boiler backplate. The latter will be delayed as I'd like to improve the overall look by incorporating some of the new Hobbyhorse castings.

Once the brakes are finished the frames can then be prepared for spraying and once that has been achieved the valve gear will be built and installed.

Now where is that GWR 2021?