Before I forget, thanks to everyone for all the help without which I'd not have achieved this. I'm not quite home and dry, but I'm absolutely convinced that I'll get there now. Sorry that it's been so long to update but each step has been tiny (as, indeed, is the model itself).

Anyway, here we are now.

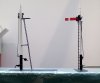

This is the reverse view, lamps and brackets in place, trimmer brackets fitted, finials fitted, step boards cut and applied and weighted lower cranks fitted. The whole signal has been fitted to a brass base which the sparks will equip with appropriate servos.

Now the complete ensemblage from the front, with a signal arm in place just because I can. The rather oversize signal cranks are in place here - I took the decision to make these of sufficient dimensions to ensure that the signal arms will work. Subsequent to this I've fitted the operating wires (photos to follow) and up to the point where the rods to the signals are in place everything works. I'm ecstatic!

This is the operating cranks at the lower end of the signal with their counterweights.

And this is the detail of the front of the signal and those over size operating cranks. These have two 0.8mm washers with holes opened up to o.5mm for the rods which are from dressmakers pins behind the cranks to give space for the operating wires, and one washer at the front. The movement is good.

Finally the prepared stanchions for the hand rails. The verticals are from 0.5mm wires with the ends compressed in a machine vice. These flattened ends have been drilled 0.4mm and the copper wire, 0.35mm, will be threaded through these. Since taking the photos I've fitted one of the uprights and it all works. The final appearance will be up to my dexterity.

BTW, the two single signals with which I started this missive are now painted and ready for final assembly, fitting the servos and installation.

Brian

. Seriously it'll be superb with the arms and links on.

. Seriously it'll be superb with the arms and links on.