JimG

Western Thunderer

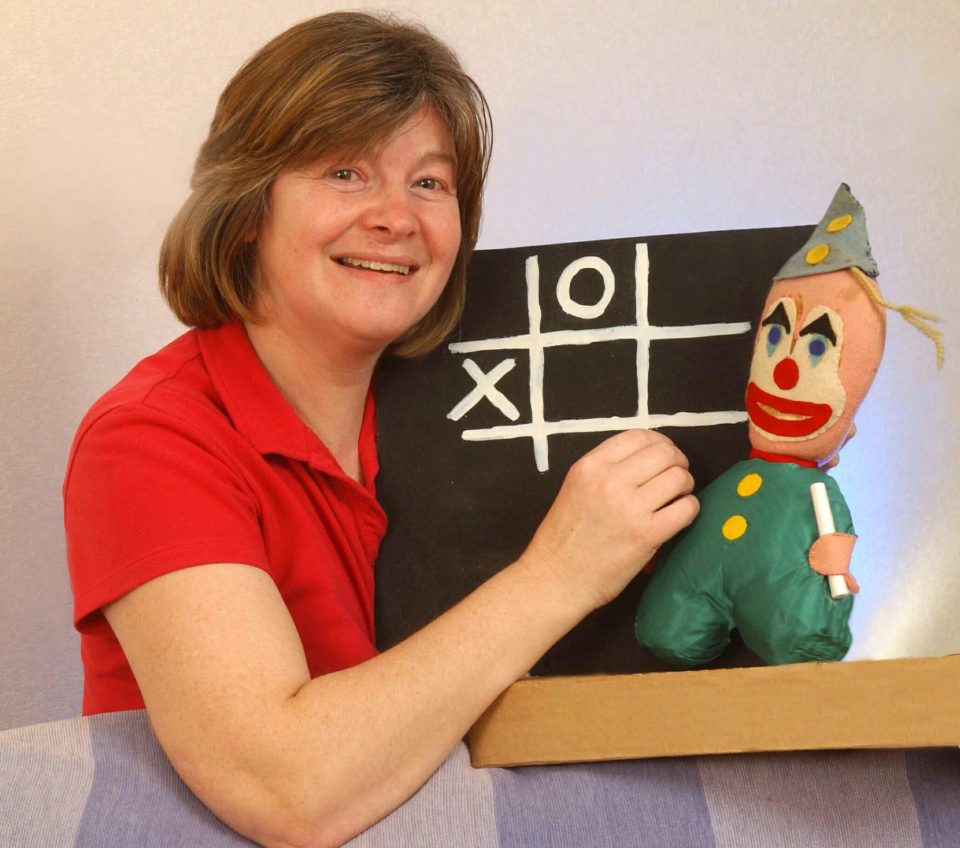

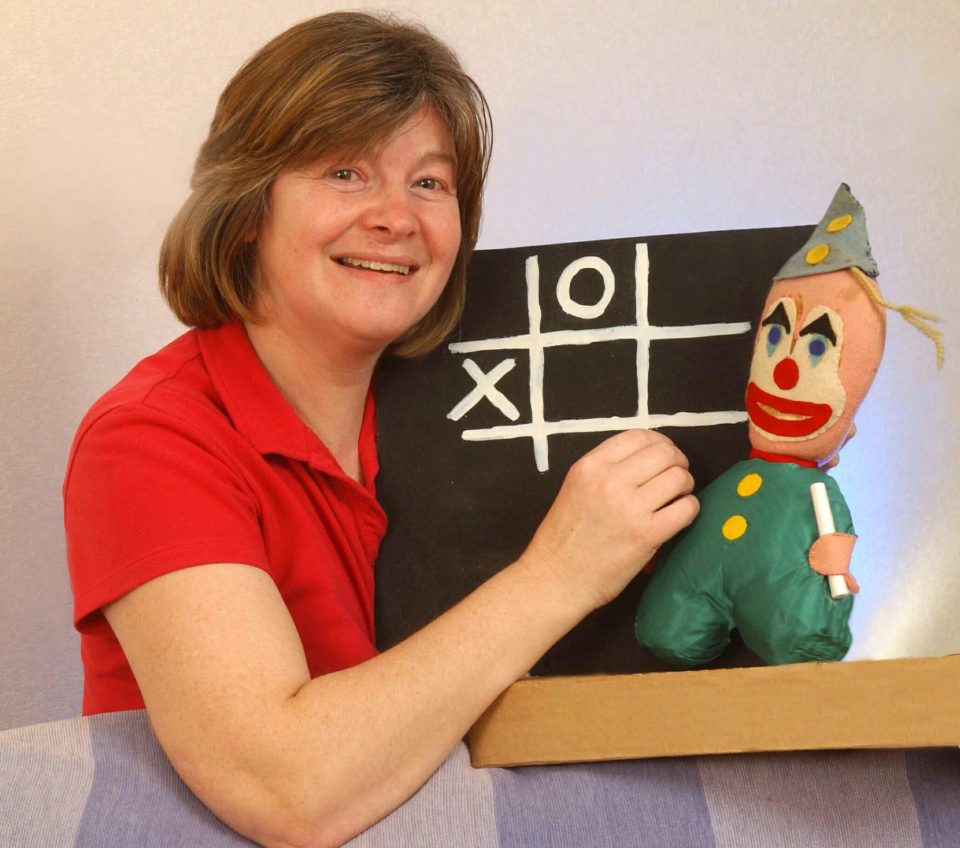

Good grief, haven’t seen that for a while.

I wonder what she’s doing now, not many jobs for test card models any more!

She's still around.

Jim.

Good grief, haven’t seen that for a while.

I wonder what she’s doing now, not many jobs for test card models any more!

JimG'll know.I did hear they reversed the image to make her right handed, whether there was any truth in it I do not know.

Happy wallpapering, I always tried to persuade the authorities paint was better.

I may get dinner tonight or it may be in the dog.

I may get dinner tonight or it may be in the dog.

I'll be moving on to the cladding next but am confused about the presence of the etched extensions which can be seen top and bottom of each etch. I can't find any reference to these, their use or, indeed, final presence so should these just be cut off? Frankly I doubt it as they look to be an important part of the etch. Can anyone advise? If not I'll give Dave a call for his advice.

Brian

I couldn't find any reference to them in the instructions either so I just cut them off.

The boiler, firebox and smokebox are relatively easy to form, the cab skin is considerably more difficult as it needs to be formed perfectly to get a good fit, the tinest error on one side is greatly magnified on the other.

Richard