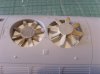

I?m not having rotating fans, but decided to make the resin fan bases removable, as I thought it might make painting a little easier, when the time comes.

There?s a tiny bit of slop when the bases are fitted to the apertures in the roof, so I positioned them as centrally as possible, then drilled a hole at each end, through the bases and into the roof?.

[attachment=7:1f6mypnt]SNV33162.JPG[/attachment:1f6mypnt]

All holes in the bases and roof were enlarged, then bolts (with 2 spacer nuts, a washer and top nut), were screwed into the holes in the roof, until they bottomed out. The bolts seemed to cut their own threads quite nicely, but I had visions of them stripping threads if they were screwed in and out too often, so it was on with the plan. The nuts were all wound down the threads, until they too, could go no further and at this point, the top nuts were soldered to the washers beneath them?.

[attachment=6:1f6mypnt]SNV33163.JPG[/attachment:1f6mypnt]

The excess bolts were snipped off and cleaned up with files and abrasive paper?.

[attachment=5:1f6mypnt]SNV33164.JPG[/attachment:1f6mypnt]

The cut down bolts were removed from the holes to allow a tiny drop of superglue to be placed in each hole, and then they were screwed back in. All nuts were then removed, the fan bases were slid over the protruding bolts and secured with the top nuts/washers.

[attachment=4:1f6mypnt]SNV33166.JPG[/attachment:1f6mypnt]

All done?.

[attachment=3:1f6mypnt]SNV33168.JPG[/attachment:1f6mypnt]

The next job was the etched fan grills and walkways?.

[attachment=2:1f6mypnt]SNV33169.JPG[/attachment:1f6mypnt]

The walkways are made from two etches, whilst the fan grills are single etches?.

[attachment=1:1f6mypnt]SNV33171.JPG[/attachment:1f6mypnt]

The fan grills were quite difficult to curve to the roof profile, but I got there in the end. After chemically blackening (which wasn?t a major success), here?s what they look like?.

[attachment=0:1f6mypnt]SNV33172.JPG[/attachment:1f6mypnt]

I?m pleased with today?s progress and managed to cross two things off the list.

More updates, as and when.

Regards

Dan

[/quote:1yt6nka6]

[/quote:1yt6nka6]

Well worth the effort Dan

Well worth the effort Dan  Just as well they're not fitted for good just yet.

Just as well they're not fitted for good just yet.