Dikitriki

Flying Squad

Hi,

I've finally managed to get back to my work bench, so I'm picking up where I left off on the Fowler.

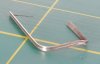

I still had a couple of the sand pipe supports to finish off, and recorded the process. Some locos have the brackets looped round the pipes, a bit like a split pin, but the Fowler's are clipped to straight brackets.

The bracket is attached to the chassis with the sand pipe resting on it.

The clip is formed,

and soldered to the bracket trapping the sand pipe.

The bracket is trimmed to length and everything tidied up.

This does make for a pretty strong support for what are pretty vulnerable components.

That's all 6 done now, so I can get back to the body.

Richard

I've finally managed to get back to my work bench, so I'm picking up where I left off on the Fowler.

I still had a couple of the sand pipe supports to finish off, and recorded the process. Some locos have the brackets looped round the pipes, a bit like a split pin, but the Fowler's are clipped to straight brackets.

The bracket is attached to the chassis with the sand pipe resting on it.

The clip is formed,

and soldered to the bracket trapping the sand pipe.

The bracket is trimmed to length and everything tidied up.

This does make for a pretty strong support for what are pretty vulnerable components.

That's all 6 done now, so I can get back to the body.

Richard