Rob Pulham

Western Thunderer

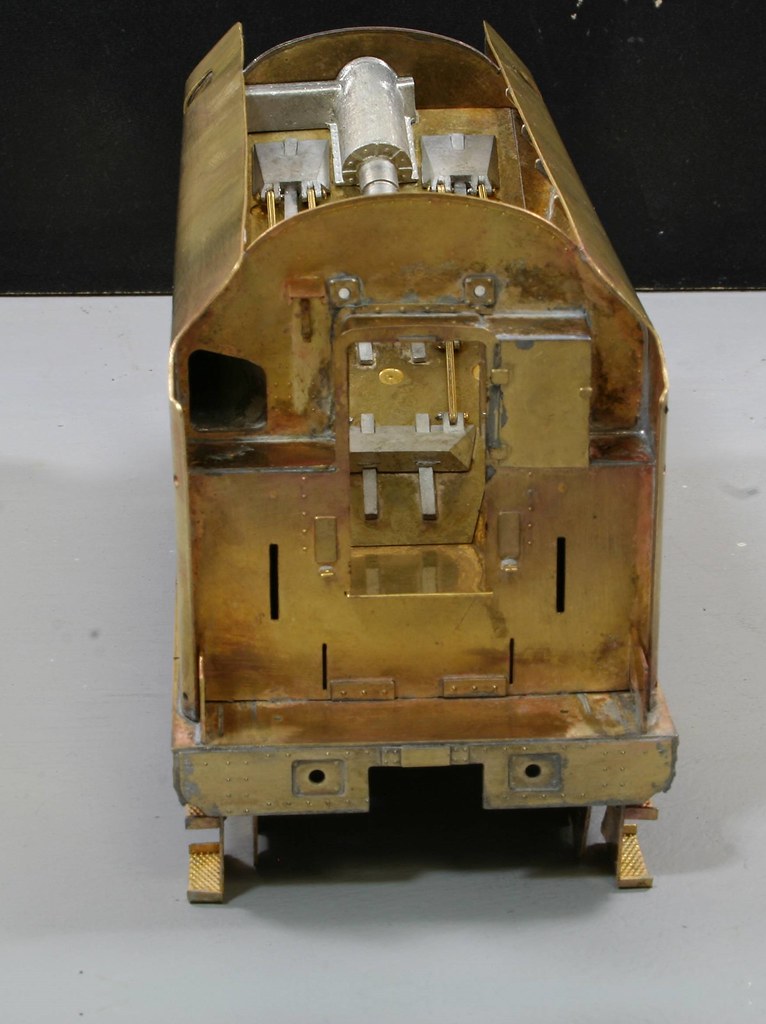

Isn't life ironic, after choosing the David Andrews Kit over the DJH offering and subsequently putting it up for sale I had a phone call on Easter Sunday afternoon asking if I could fit in building a DJH Streamlined Coronation as soon as possible. The gent that I am building the J6 for is in no rush so I decided to give it a go.

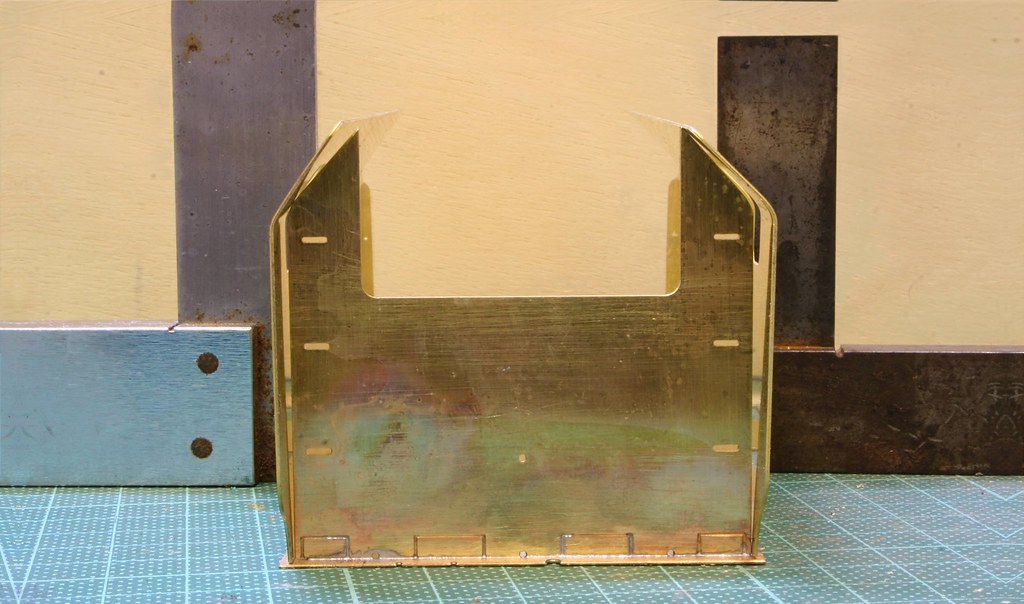

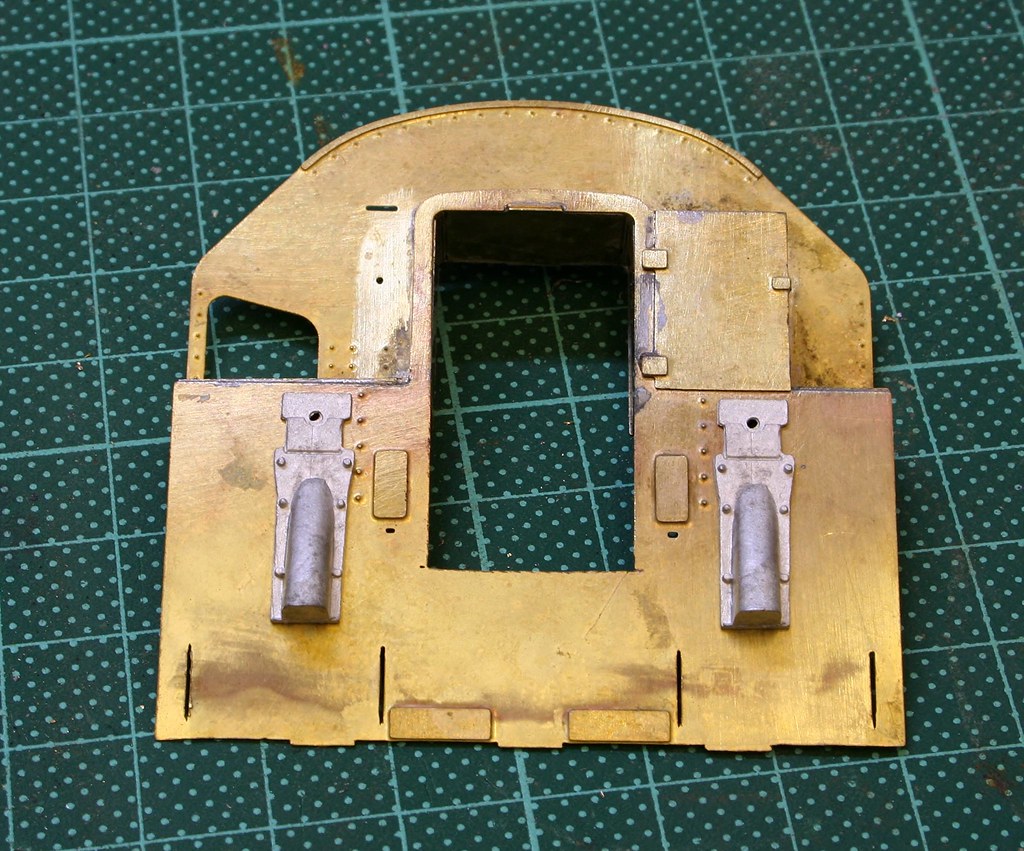

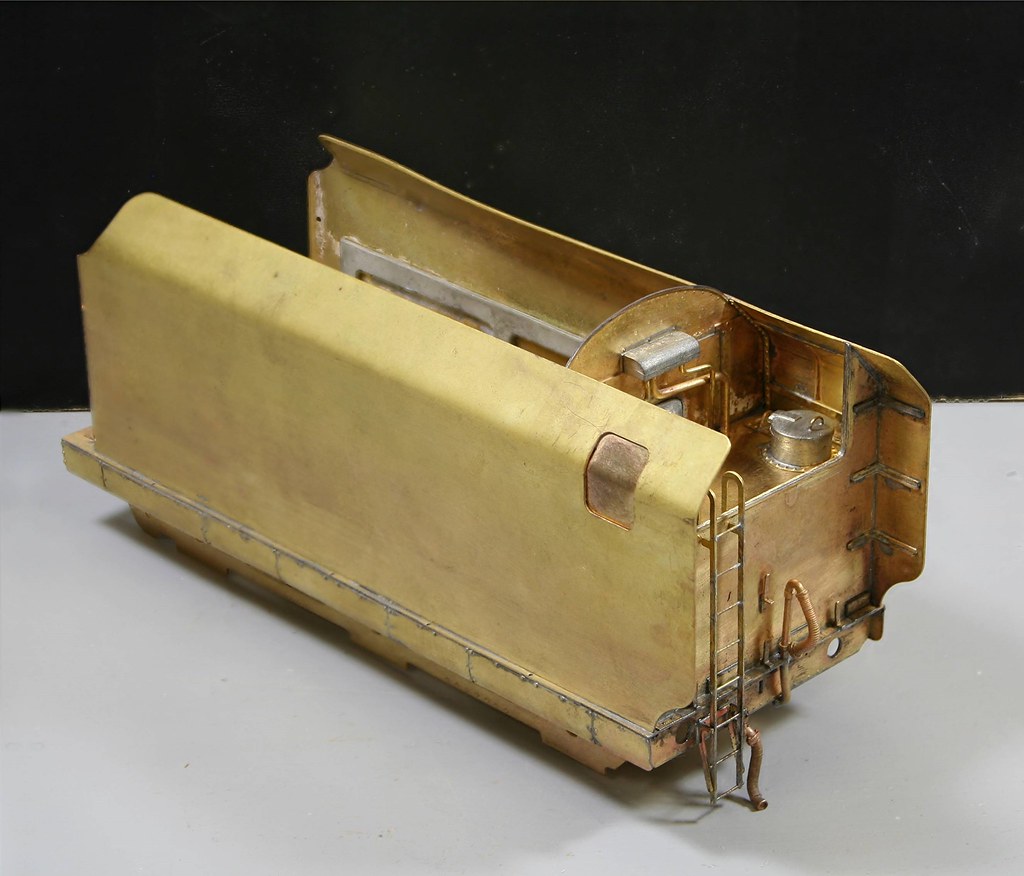

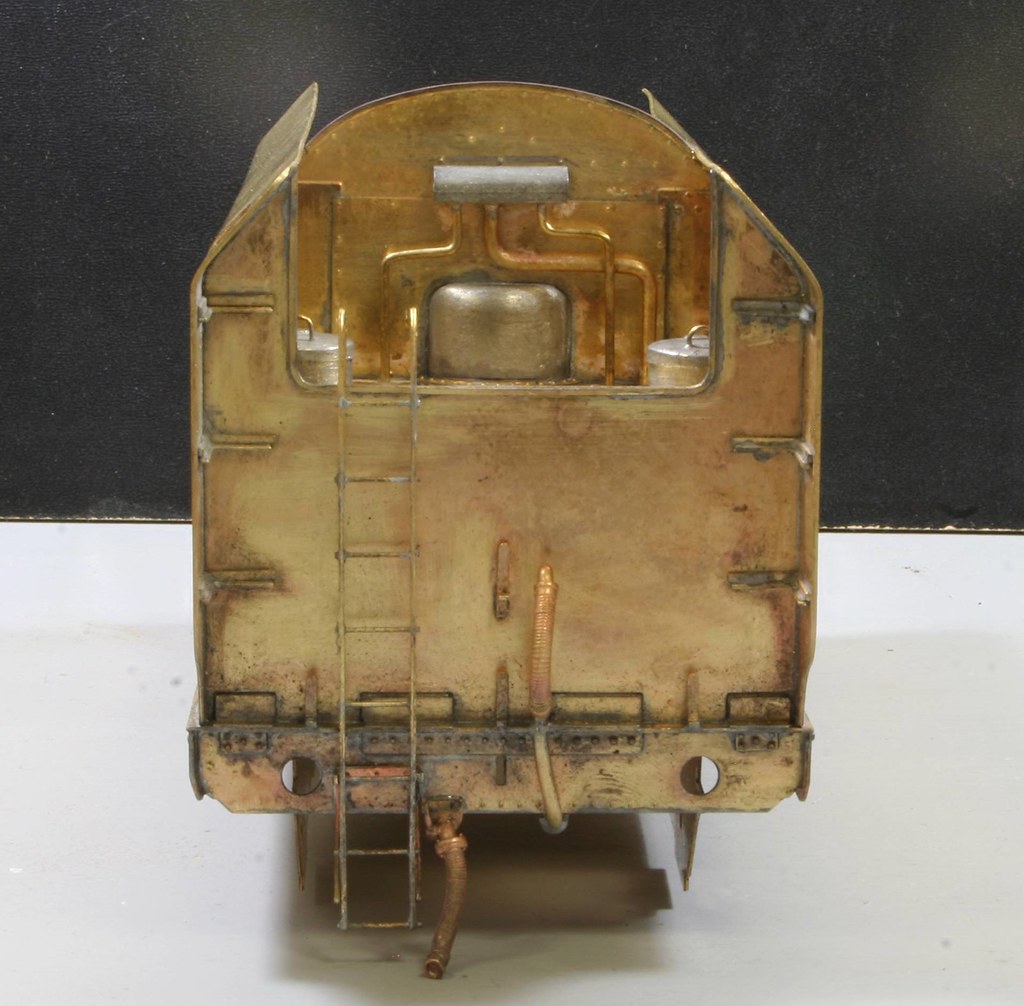

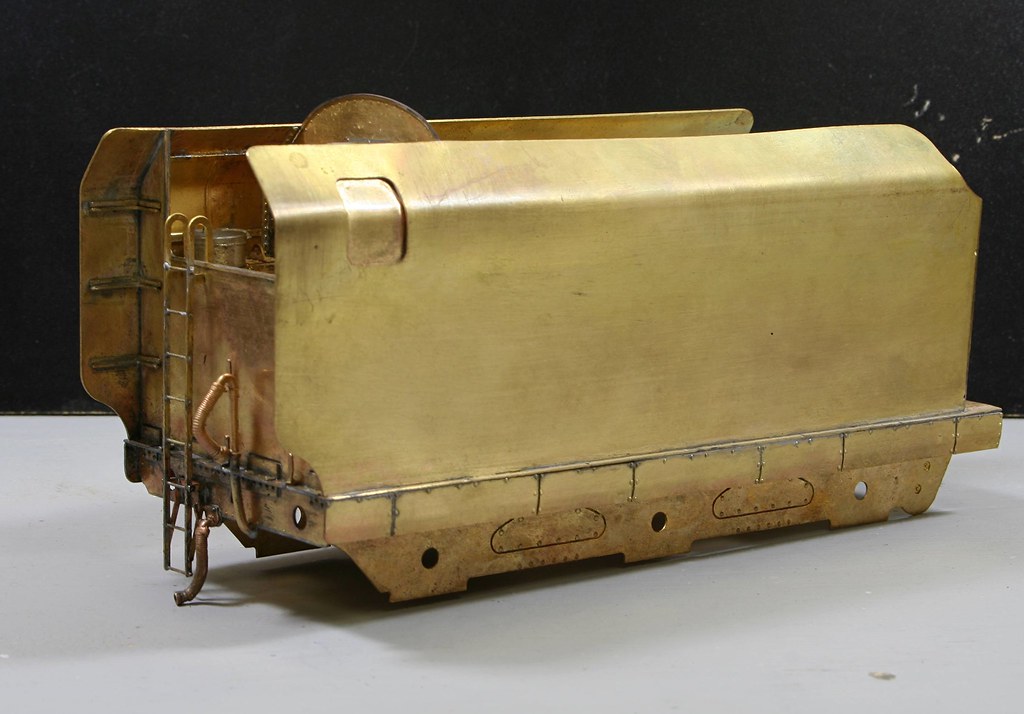

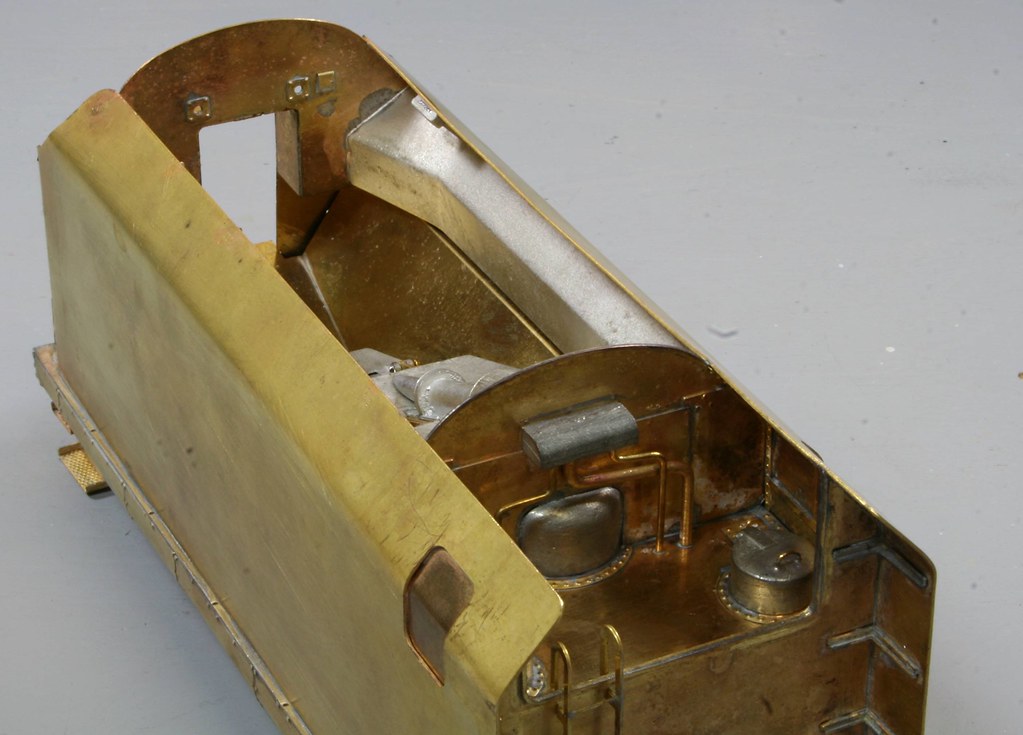

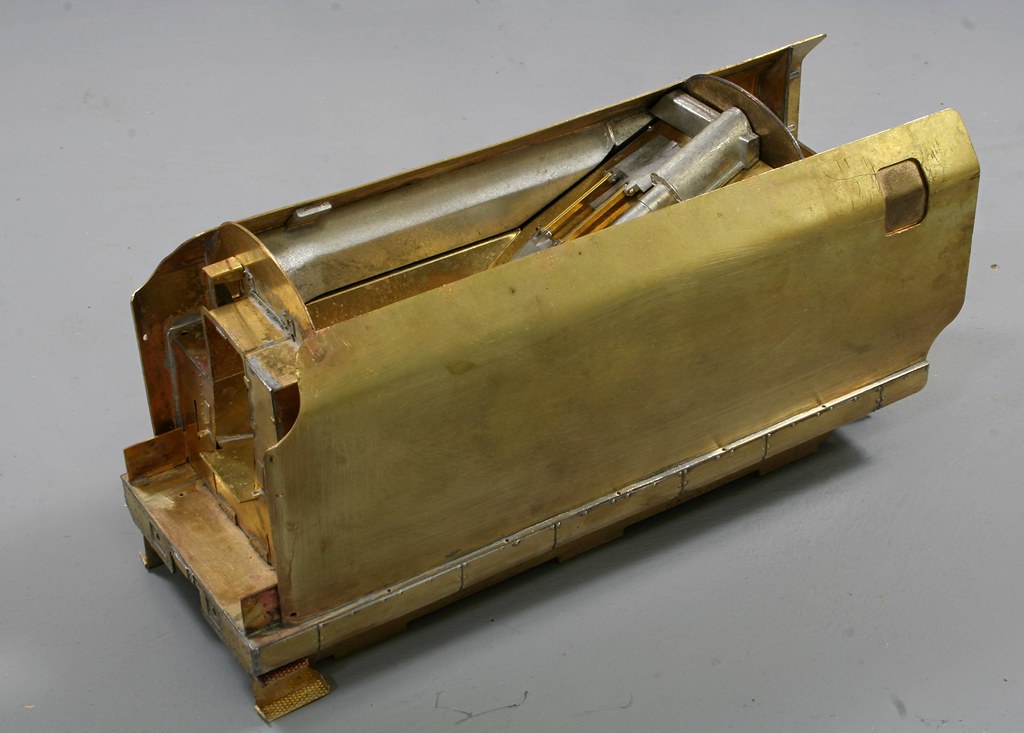

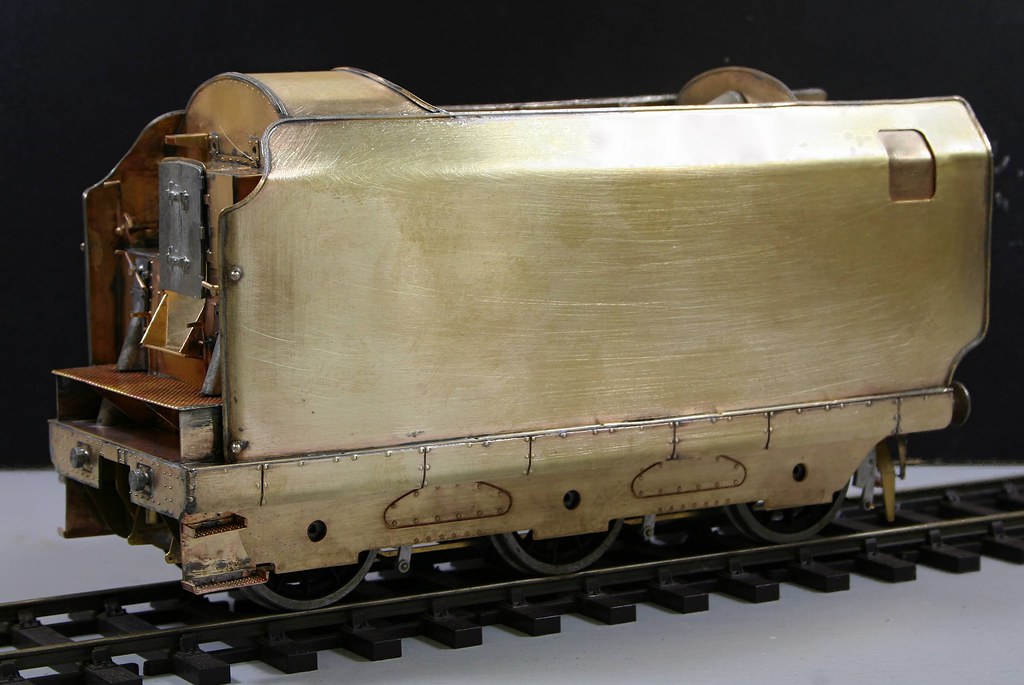

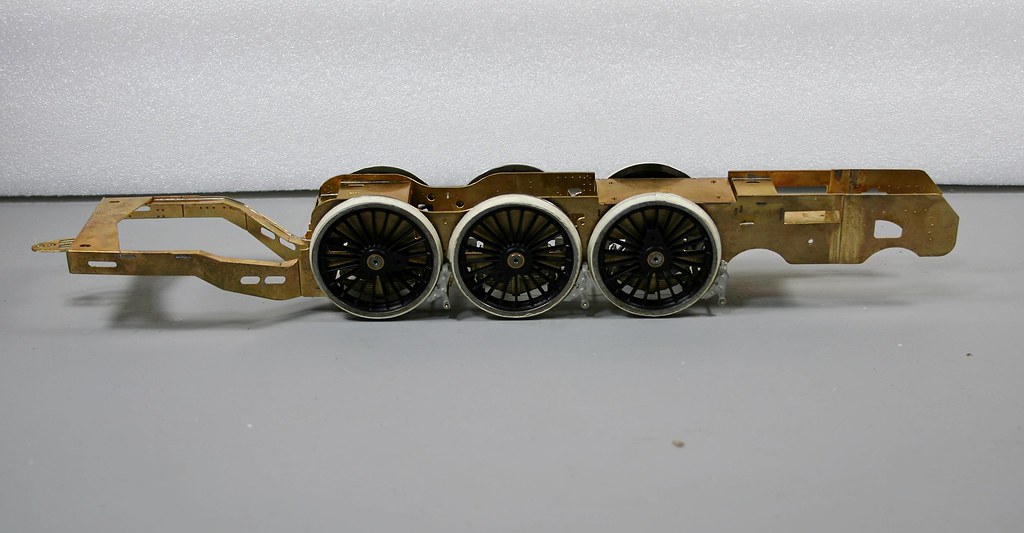

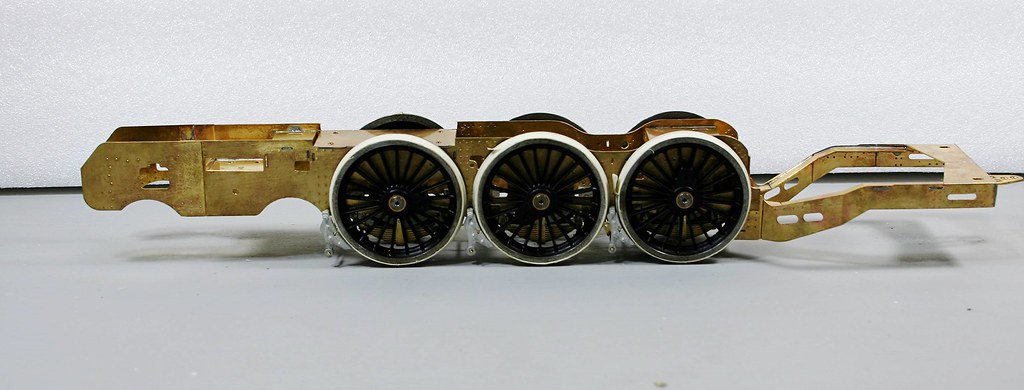

The kit was dult delivered on Sunday evening and by bedtime I had the basic tender chassis together.

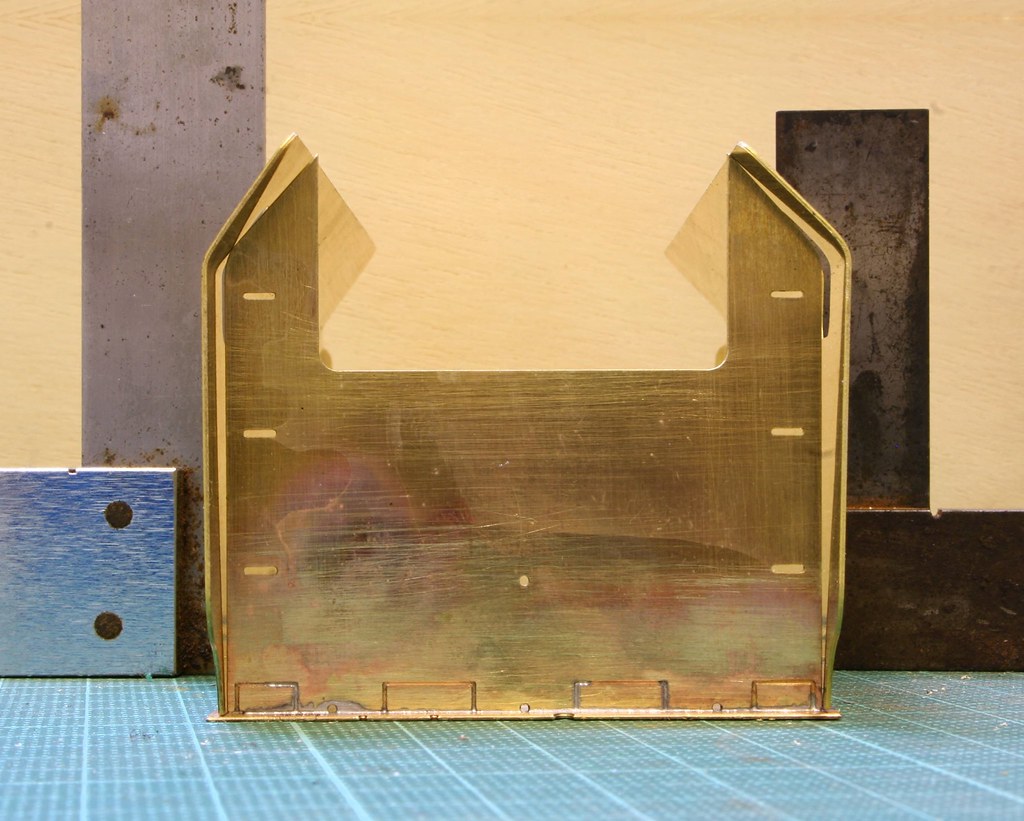

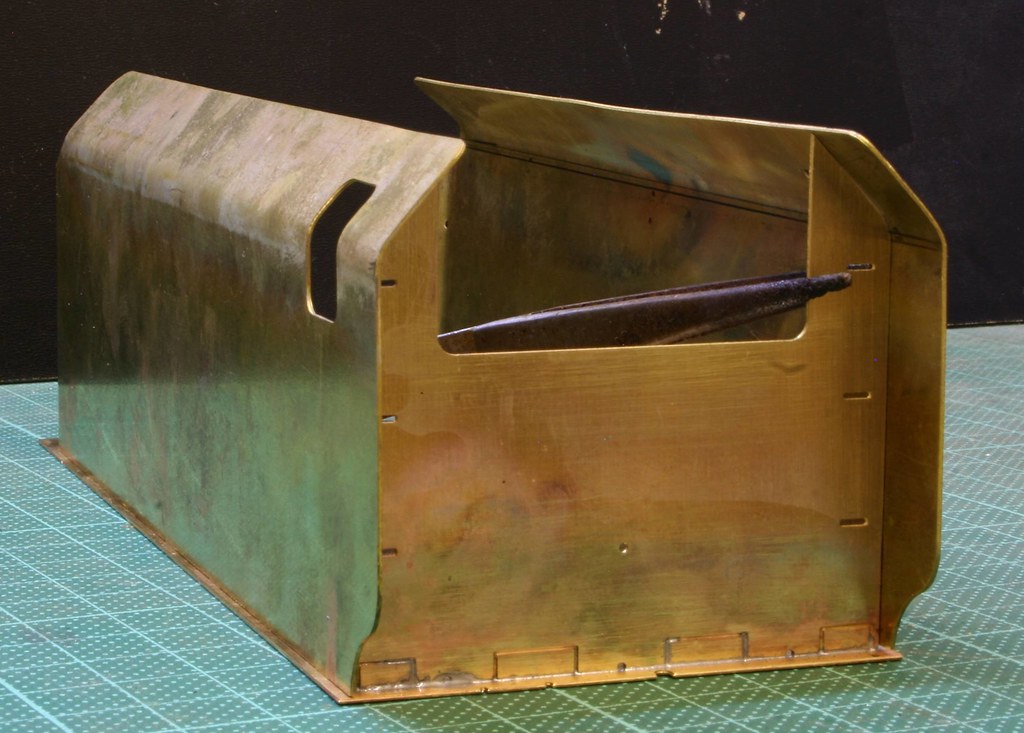

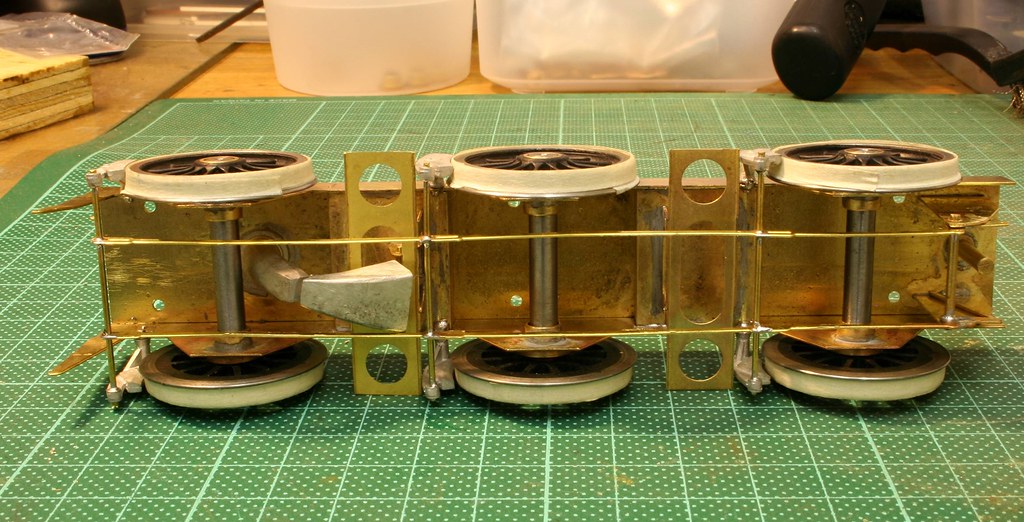

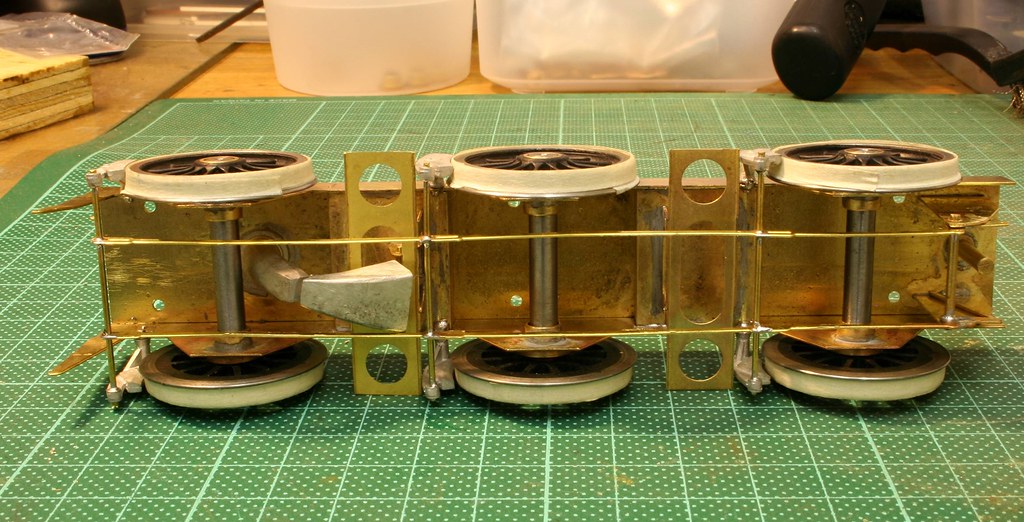

Another couple of hours on Monday morning had the tender chassis complete, so far so good.

To a degree I feel that any criticism that I make of this kit is a bit like sour grapes given that I chose the David Andrews kit over the Tower/DJH version .

That said, hiding what I find doesn't help anyone else who may decide to build one of these.

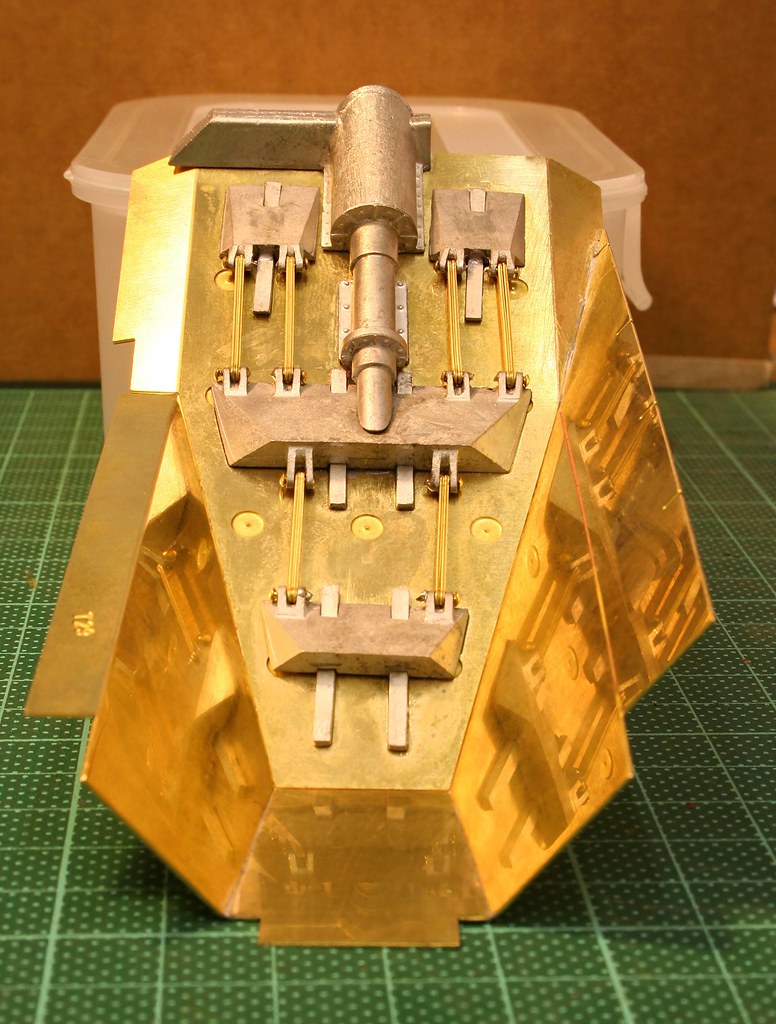

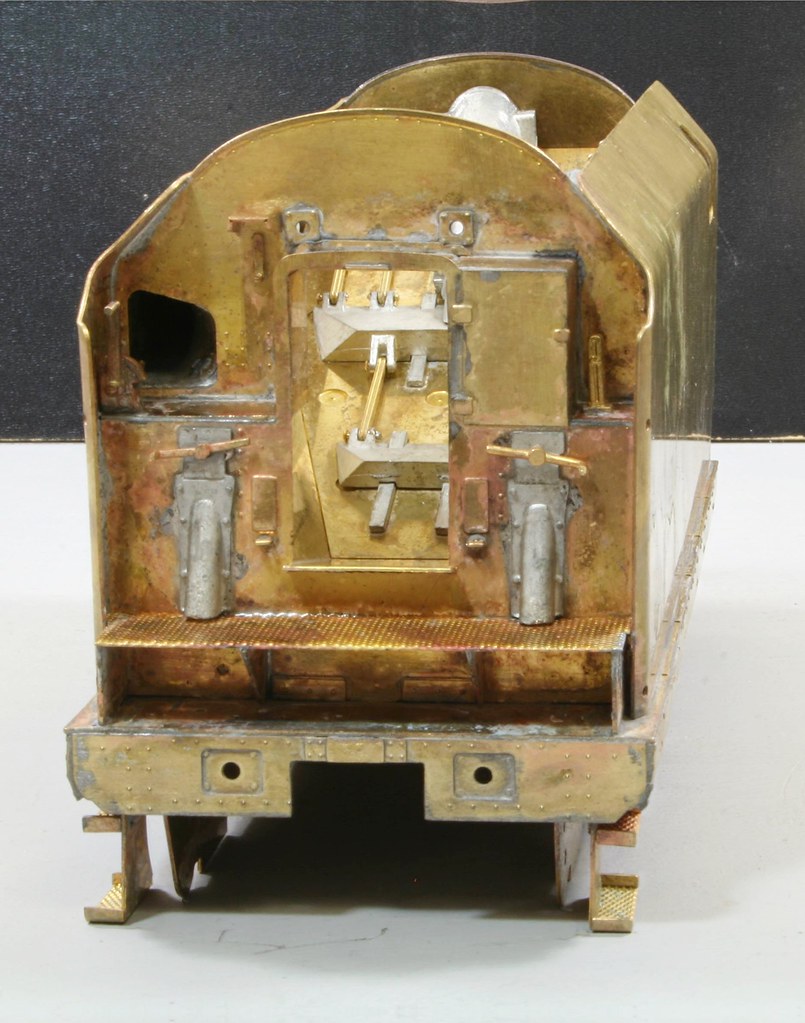

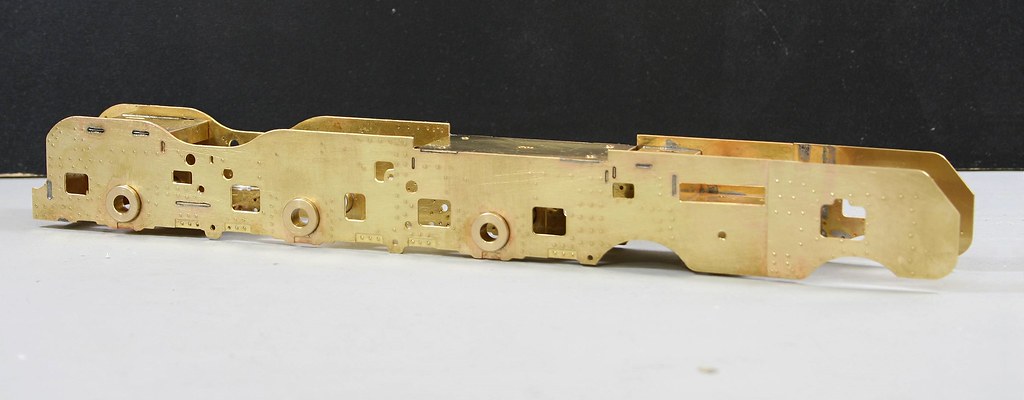

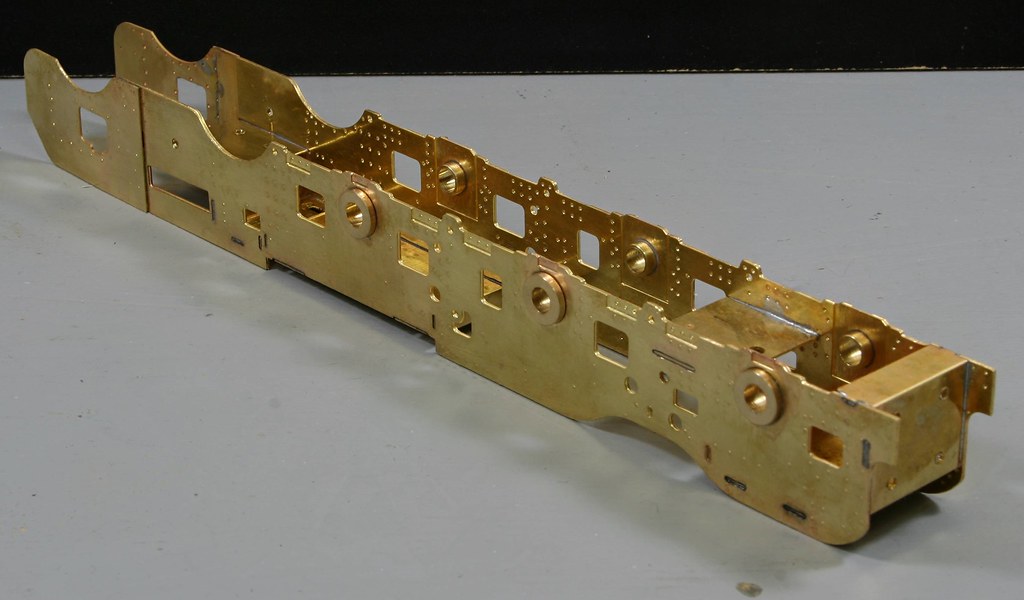

The key issue with the tender chassis is that the cross members that fit between the wheels are a single half etched layer in the middle section, which makes them very vulnerable to bending. This and other areas where key parts are a single half etched layer (more on that later) are particularly noticeable to me when this build comes right on the heels of building the MOK LMS tender which is prototypically similar in many respects.

Although I don't know the name of the loco that the model is to ultimately represent I have been asked to build it as one of the double chimney red ones - Apparently there were some differences on the red ones over the first few blue ones (I had originally planned to build mine as Duchess of Hamilton in Blue when Coronation was masquerading as DOH while DOH went to America masquerading as Coronation, confused yet.....). Luckily the kit also came with a loan of the Wild Swan/NRM Loco Priles book for the Coronation Pacifics.

The kit was dult delivered on Sunday evening and by bedtime I had the basic tender chassis together.

Another couple of hours on Monday morning had the tender chassis complete, so far so good.

To a degree I feel that any criticism that I make of this kit is a bit like sour grapes given that I chose the David Andrews kit over the Tower/DJH version .

That said, hiding what I find doesn't help anyone else who may decide to build one of these.

The key issue with the tender chassis is that the cross members that fit between the wheels are a single half etched layer in the middle section, which makes them very vulnerable to bending. This and other areas where key parts are a single half etched layer (more on that later) are particularly noticeable to me when this build comes right on the heels of building the MOK LMS tender which is prototypically similar in many respects.

Although I don't know the name of the loco that the model is to ultimately represent I have been asked to build it as one of the double chimney red ones - Apparently there were some differences on the red ones over the first few blue ones (I had originally planned to build mine as Duchess of Hamilton in Blue when Coronation was masquerading as DOH while DOH went to America masquerading as Coronation, confused yet.....). Luckily the kit also came with a loan of the Wild Swan/NRM Loco Priles book for the Coronation Pacifics.