Dikitriki

Flying Squad

Hi,

Chassis is just about ready for the wheels now. I've attached the driving wheels springs to retain the hornblocks. The rear ones are soldered on, the front ones are screw on so I can drop the inside valve gear. I have checked that our new style cranks and 4 eccentrics fit between the hornblocks, and they do with nice clearance to spare; so no problems getting the inside motion in .....other than putting it together in the first place

.....other than putting it together in the first place

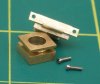

The front driving axle springs are coil, so I had to solder a plate to the bottom of the casting and sections of angle to either side of the hornguides. The angle was drilled and tapped 14BA.

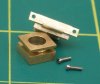

and with the overlay on and bearings in place.

Wheels next, coupling rods and motor, then the inside motion.

Richard

Chassis is just about ready for the wheels now. I've attached the driving wheels springs to retain the hornblocks. The rear ones are soldered on, the front ones are screw on so I can drop the inside valve gear. I have checked that our new style cranks and 4 eccentrics fit between the hornblocks, and they do with nice clearance to spare; so no problems getting the inside motion in

.....other than putting it together in the first place

.....other than putting it together in the first place

The front driving axle springs are coil, so I had to solder a plate to the bottom of the casting and sections of angle to either side of the hornguides. The angle was drilled and tapped 14BA.

and with the overlay on and bearings in place.

Wheels next, coupling rods and motor, then the inside motion.

Richard