You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Finney7 West Country - 34023 Blackmore Vale

- Thread starter 7mmMick

- Start date

AJC

Western Thunderer

AJC................yep thats the one.......... and wots an URL??

The web address or link that appears at the top of the page, e.g., Western Thunder (it stands for 'Un Real Location in web speak). You can highlight it, copy and paste it and that will link to precisely the original place you want to refer to. Not everyone can (or can be bothered to) work out what is meant from the description so copying it makes it easy.

Adam

daifly

Western Thunderer

AdamThe web address or link that appears at the top of the page, e.g., Western Thunder (it stands for 'Un Real Location in web speak).

I'm hoping that you are having a little joke here. URL stands for Uniform Resource Locator - or 'address' in layman's terms.

Dave

AJC

Western Thunderer

Adam

I'm hoping that you are having a little joke here. URL stands for Uniform Resource Locator - or 'address' in layman's terms.

Dave

I'm getting things wrong. that's what I'm doing...

Or writing what I wish it meant rather than looking it up. It's a Friday, but that's no excuse.

Adam

Last edited:

7mmMick

Western Thunderer

Hello Mick--------Theres a "front end" image on David Christie Flickr Steam Railways from the 60s album (page 2) of Blackmore Vale in 1964 .The conduit runs to the lights are different to how you have them on your very excellent build.With batteries in place conduit runs varied quite a bit.Tonys Weymouth is a case in point.Hope this of use...................Regards....etc....

Hi 2-Bill,

Cracking shot that, not one i’ve seen to be fair. On page one of my thread is the photograph I’m working form, dated June 61. On this photo 34023 has the conduit I have modelled. I’m assuming the later change was completed when the tender was modified?

Cheers

Mick

Last edited:

2-Bil

Western Thunderer

Fellow Travellers .....still none the wiser with" web speak.".........but at least Mick,ll know wot photo is being talked about ....................and.theres some very good images in general on that site .Cant help with dates MICK but im betting someone will be along who can......respects BW

Last edited:

Dan Randall

Western Thunderer

URL stands for Uniform Resource Locator - or 'address' in layman's terms.

I didn't know that (though I prefer Adam's definition of it!). Thanks Dave.

Regards

Dan

Scale7JB

Western Thunderer

Have a look at the below on Youtube if you get chance. I have it on in the background whilst working on Blackmore Vale ( who briefly features ). There's a great sequence showing Royal Mail at her best, a trip down memory lane;

Cheers

Mick

Not the biggest fan of the southern, but enjoyed every second of that video. I do like a Bulleid. Shame there wasn't anything of Taw Valley.

It does show just how many Bulleid Pacifics we have with us now. A few too many?

JB.

oldravendale

Western Thunderer

In absolute terms one could argue that there are too many Bulleid Pacifics, but they weren't bought at the expense of any other classes and give the preserved railways the opportunity of operating locos which are large and impressive and which otherwise wouldn't be available.

Personally I'd also like to see a goodly number of them gathered in one of the steam sheds. They are possibly the only class which is available in sufficient numbers to reproduce a scene from one of the mid to smaller size SR sheds, like Basingstoke. Throw in a Standard 5, Class 4 2-6-0 and a couple of Standard 2-6-4 tanks and the scene would be complete.

When I win the lottery.........

Brian

Personally I'd also like to see a goodly number of them gathered in one of the steam sheds. They are possibly the only class which is available in sufficient numbers to reproduce a scene from one of the mid to smaller size SR sheds, like Basingstoke. Throw in a Standard 5, Class 4 2-6-0 and a couple of Standard 2-6-4 tanks and the scene would be complete.

When I win the lottery.........

Brian

7mmMick

Western Thunderer

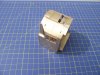

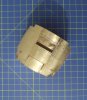

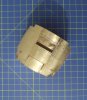

Lots going on behind the scenes and all by the book really. The only thing I've deviated with is making the axle box springs removable. I've constructed my own rendition of the @mick00 version. Reading his thread I realised there would be lots of repetition in making the springs removable so to make life much easier I knocked up a quick jig to make sure all the plates lined up post cutting. This work won't be wasted as having enjoyed the build that much so far I'm sure i'll build another one of these kits at some stage. A few grab shots of the jig in action, the N/S strip is scrap etch from the kit recycled;

The plates were then soldered to the slightly modified ( a bit filled off ) springs. Having constructed both the springs and brake gear, which are all made from laminated etch, I have found a new loathing for this approach. Laminated construction has it's place but too much is the work of Beelzebub and all his demons So here are the plates fitted to the bottom of the axle boxes and springs.

So here are the plates fitted to the bottom of the axle boxes and springs.

You can see that the wider plate has the centre removed once all is fitted and checked so the axle box can be removed. A fair bit of work here and i'm glad it's sorted I can tell you! Sick of the tarnishing of the brass BTW. Can't keep anything shinny. The next one will be all N/S !

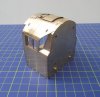

I've also been on with the motion bracket and cylinder assembly. Fairly straight forward. The kit advises fitting all the castings before the wrapper. Not a great idea as the wrapper is slightly oversize to all allow it to be dressed back for a perfect fit. The best way I thought was to fit the wrapper and then the detail gubbins afterwards. Only issue there is the wrappers have to be fitted with the casing on so they line up, meaning that this stage has to wait a while.

A quick shot of the frames at this stage;

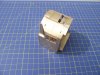

I've not mentioned the wheel overlays but all are now fitted and really lift the look of the wheels IMHO. And finally a couple of shots of things together. Must get a bigger work matt as the thing won't fit now!

On the home stretch now. After the holidays is the remainder of the brake gear ( not in the photos but almost complete at the moment ) beachhead and all the fiddly pipe runs. Oh and the casing detailing

Mick

The plates were then soldered to the slightly modified ( a bit filled off ) springs. Having constructed both the springs and brake gear, which are all made from laminated etch, I have found a new loathing for this approach. Laminated construction has it's place but too much is the work of Beelzebub and all his demons

So here are the plates fitted to the bottom of the axle boxes and springs.

So here are the plates fitted to the bottom of the axle boxes and springs.

You can see that the wider plate has the centre removed once all is fitted and checked so the axle box can be removed. A fair bit of work here and i'm glad it's sorted I can tell you! Sick of the tarnishing of the brass BTW. Can't keep anything shinny. The next one will be all N/S !

I've also been on with the motion bracket and cylinder assembly. Fairly straight forward. The kit advises fitting all the castings before the wrapper. Not a great idea as the wrapper is slightly oversize to all allow it to be dressed back for a perfect fit. The best way I thought was to fit the wrapper and then the detail gubbins afterwards. Only issue there is the wrappers have to be fitted with the casing on so they line up, meaning that this stage has to wait a while.

A quick shot of the frames at this stage;

I've not mentioned the wheel overlays but all are now fitted and really lift the look of the wheels IMHO. And finally a couple of shots of things together. Must get a bigger work matt as the thing won't fit now!

On the home stretch now. After the holidays is the remainder of the brake gear ( not in the photos but almost complete at the moment ) beachhead and all the fiddly pipe runs. Oh and the casing detailing

Mick

mickoo

Western Thunderer

.......beachhead.......holiday mode already I see

With you on the laminated springs, cast brass ones next time I think.

NS is much better solders nice too, you might find the cab harder to form in NS so it needs to go down a gauge really but then the whole sheet would be too thin. It's something on my to do pile after the B1.

With you on the laminated springs, cast brass ones next time I think.

NS is much better solders nice too, you might find the cab harder to form in NS so it needs to go down a gauge really but then the whole sheet would be too thin. It's something on my to do pile after the B1.

David Boorman

Active Member

In your 12th September post you, mention that you will be taking a different approach for the springing of the delta truck. Maybe I've missed any further explanation but I'm certainly still holding my breath (figuratively!) - please put me out of my misery! I built an original MF BLP kit many (too many) years ago and I found the single spring wire unsatisfactory and 'bodged' with extra springs to stop either side wheel lifting - especially when running (even slowly) in reverse. I so want to encounter a well engineered solution!

David

David

P A D

Western Thunderer

L

I've not mentioned the wheel overlays but all are now fitted and really lift the look of the wheels IMHO. And finally a couple of shots of things together. Must get a bigger work matt as the thing won't fit now.

Mick

Hi Mick,

If you don't mind being the odd one out in the F7 camp, Green A2 cutting mats are only £8.00 from The Works! Link below. Super build by the way.

Cheers,

Peter

Books | Art & Craft | Games & Toys | Stationery | Gifts - The Works

7mmMick

Western Thunderer

In your 12th September post you, mention that you will be taking a different approach for the springing of the delta truck. Maybe I've missed any further explanation but I'm certainly still holding my breath (figuratively!) - please put me out of my misery! I built an original MF BLP kit many (too many) years ago and I found the single spring wire unsatisfactory and 'bodged' with extra springs to stop either side wheel lifting - especially when running (even slowly) in reverse. I so want to encounter a well engineered solution!

David

Hi David,

You've not missed it as i'm still pondering what to do here. Like you this build suffers with the Delta truck lifting on the curves. Asking one piece of steel wire to cope with both side control and downward force seems a bridge too far. I tried to do away with the steel wire completely and use two sections of phosphor bronze for both downward pressure and side control but i'm not happy with that either. At the moment i've reinstated the steel wire for side control only and am looking at a coil sprung down force solution. I'm happy all is hidden from view I just need to get it fitted and running trials will commence. Pictures soon I hope.

Hi Mick,

If you don't mind being the odd one out in the F7 camp, Green A2 cutting mats are only £8.00 from The Works! Link below. Super build by the way.

Cheers,

Peter

Books | Art & Craft | Games & Toys | Stationery | Gifts - The Works

But everything F7 is BLUE

I will have to invest in a larger one though. And probably a light tent in the near future. The bank manager may not sanction this at the minute. The issue I always have with money in my hand for modelling is that there's always another kit which seems to come before all the boring bits like tools and gadgets

I will have to invest in a larger one though. And probably a light tent in the near future. The bank manager may not sanction this at the minute. The issue I always have with money in my hand for modelling is that there's always another kit which seems to come before all the boring bits like tools and gadgets

Mick

Last edited:

David Boorman

Active Member

Hi Mick,

Thank you for 'exposing' the challenge! I recall someone telling me years ago that the 'mechanics' of the rim shape and the rail head shape plus the 'push' on the delta truck - all when in reverse - would inevitably lead to one wheel or the other trying to ride up if there is the slightest curvature on the track. The tendency to ride up on curves would also occur when running forward but it would not be as noticeable. I can't remember who told me that - it could even have been Martin! If that is the case, it would appear logical that the greater the downforce on the rear of the truck, the less likelihood of riding up. Thinking about that I wonder if a combination of lead weight added across the top of the truck and maybe two thickish PB strips in appropriate locations to provide an almost 'solid' stop to upward movement of the truck relative to the body might work. When I get a little further with my BLP I'll be having a go at this. What baffles me is why you and I appear to be the only ones to have concern about this! Does this mean others never run their locos in reverse?

David

Thank you for 'exposing' the challenge! I recall someone telling me years ago that the 'mechanics' of the rim shape and the rail head shape plus the 'push' on the delta truck - all when in reverse - would inevitably lead to one wheel or the other trying to ride up if there is the slightest curvature on the track. The tendency to ride up on curves would also occur when running forward but it would not be as noticeable. I can't remember who told me that - it could even have been Martin! If that is the case, it would appear logical that the greater the downforce on the rear of the truck, the less likelihood of riding up. Thinking about that I wonder if a combination of lead weight added across the top of the truck and maybe two thickish PB strips in appropriate locations to provide an almost 'solid' stop to upward movement of the truck relative to the body might work. When I get a little further with my BLP I'll be having a go at this. What baffles me is why you and I appear to be the only ones to have concern about this! Does this mean others never run their locos in reverse?

David

oldravendale

Western Thunderer

Just a quick comment, and respecting all the very well reasoned comments about the delta truck.......

Mickoo made my F7 Light Pacific precisely as per the instructions. It's the one we show on the Finney7 stand at exhibitions. However, it's a working loco and runs in both directions often on my club layout which, in all fairness, features less than perfect track. Minimum radius is a little less than 6 ft.

The kit as designed works. That's not to say that there are no other and possibly more sophisticated ways of killing this particular cat.

Brian

Mickoo made my F7 Light Pacific precisely as per the instructions. It's the one we show on the Finney7 stand at exhibitions. However, it's a working loco and runs in both directions often on my club layout which, in all fairness, features less than perfect track. Minimum radius is a little less than 6 ft.

The kit as designed works. That's not to say that there are no other and possibly more sophisticated ways of killing this particular cat.

Brian

David Boorman

Active Member

Brian,

I'm genuinely pleased to see your comment. Food for thought!

David

I'm genuinely pleased to see your comment. Food for thought!

David

Cab

7mmMick

Western Thunderer

Whilst work continues with the chassis i've taken a break and had a couple of days working on the body. I think the resin moulding lulled me into a false sense of security as I thought there wasn't much work here! So firstly I finished off the cab area. There are a number of sub assemblies to make up on the bench before they are installed, the reverser;

And then the injector taps. I've not yet fitted the slacking pipe as this will be one of the final details and will probably rest in a metal bucket. This is how I remember 92 Squadron being on the NYMR when I volunteered there. I also remember how important the slack pipe was!! Every ex BR man liked a clean footplate and the slacking pipe seemed to be in constant use!

Fitted to the cab;

I found this site a real help when fitting the cab out, although the image can make you feel a little sick if you let in run too long , it can be paused

Blackmoor Vale 21C123

All roof details and internals are now complete;

As you have probably noticed I've opted for the @mickoo method for securing the backhead. I'll let the pictures do the talking but needless to say this makes life so much easier and will allow me to continually check the fit of the pipe work as there's a lot to squeeze in!

I used some spare brass angle and 8BA nuts and bolts to knock up the fitting.

And then the injector taps. I've not yet fitted the slacking pipe as this will be one of the final details and will probably rest in a metal bucket. This is how I remember 92 Squadron being on the NYMR when I volunteered there. I also remember how important the slack pipe was!! Every ex BR man liked a clean footplate and the slacking pipe seemed to be in constant use!

Fitted to the cab;

I found this site a real help when fitting the cab out, although the image can make you feel a little sick if you let in run too long , it can be paused

Blackmoor Vale 21C123

All roof details and internals are now complete;

As you have probably noticed I've opted for the @mickoo method for securing the backhead. I'll let the pictures do the talking but needless to say this makes life so much easier and will allow me to continually check the fit of the pipe work as there's a lot to squeeze in!

I used some spare brass angle and 8BA nuts and bolts to knock up the fitting.

Casing

7mmMick

Western Thunderer

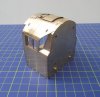

I then moved onto the casing and fitted the overlays and side ladders. The ladders are very fiddly indeed and are really flimsy without the pins. Once the pins (0,6mm brass wire) are fitted they are very sturdy. I took a couple of bench shots with the phone to illustrate;

@mickoo advised to grind a small recess in the casing at the pin location. This allows a 'blob' of solder to remain on the rear of the pin without effecting the fit of the ladder. If you don't do this then the tiny amount of solder holding the pin just isn't enough. You also need to fit the inspection covers pre final fitting of the ladder. I've tried to solder as much as possible away from the resin before fitting as that way you know it's well fixed. Overlays in place, just two more small ones at the front to fit;

The overlay around the chimney is not straight forward and takes some time and fettling to fit properly, I made this up as a sub assembly on the bench and made sure the joints were all well soldered. And finally I've added the smokebox door details. Working from my picture of 34023 I've adjusted the smokebox door handles, it's no good having it the same as all the other Finney BLP's out there

All that's left ( I say all, it will be a couple of days work!!) on the body are the smoke deflectors and the pipe runs for lubricators and lights at the front end. Chassis update soon and it's looking almost there !

Mick

@mickoo advised to grind a small recess in the casing at the pin location. This allows a 'blob' of solder to remain on the rear of the pin without effecting the fit of the ladder. If you don't do this then the tiny amount of solder holding the pin just isn't enough. You also need to fit the inspection covers pre final fitting of the ladder. I've tried to solder as much as possible away from the resin before fitting as that way you know it's well fixed. Overlays in place, just two more small ones at the front to fit;

The overlay around the chimney is not straight forward and takes some time and fettling to fit properly, I made this up as a sub assembly on the bench and made sure the joints were all well soldered. And finally I've added the smokebox door details. Working from my picture of 34023 I've adjusted the smokebox door handles, it's no good having it the same as all the other Finney BLP's out there

All that's left ( I say all, it will be a couple of days work!!) on the body are the smoke deflectors and the pipe runs for lubricators and lights at the front end. Chassis update soon and it's looking almost there !

Mick