jamiepage

Western Thunderer

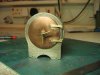

Some bits of the smokebox have been made,most of which will be a fabrication from simple machined shapes. Currently awaiting a lump of cored bronze for the smokebox proper, but the rear ring and saddle have been machined.

The saddle will be bolted then silver soldered to the smokebox itself, the fabrication then being milled away underneath as necessary to allow it to sit down snugly over the cylinder/ steamchest.

The rear ring is machined , from the left, to push into the smokebox proper, a raised decorative brass banding for smokebox rear, a land to take boiler cladding, then finally an extension to meet a G1 Project boiler which will slide/ push fit in..

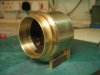

The smokebox door was turned from an old casting. Much larger than required, it turned down well enough stuck with double sided tape to a mandrel and a live centre holding it in position. Unfortunately, some blow holes appeared and which still show so will need filling.

The boss was turned as an integral part of the door.

Slots were milled to take pre- drilled and partially shaped hinges.

Silver soldered in place and cleaned up, rivets etc were added to finish, then it was tried for size in the embossed smokebox front.

(Yes, these three embossed rivets were on the wrong side.) ^

The saddle will be bolted then silver soldered to the smokebox itself, the fabrication then being milled away underneath as necessary to allow it to sit down snugly over the cylinder/ steamchest.

The rear ring is machined , from the left, to push into the smokebox proper, a raised decorative brass banding for smokebox rear, a land to take boiler cladding, then finally an extension to meet a G1 Project boiler which will slide/ push fit in..

The smokebox door was turned from an old casting. Much larger than required, it turned down well enough stuck with double sided tape to a mandrel and a live centre holding it in position. Unfortunately, some blow holes appeared and which still show so will need filling.

The boss was turned as an integral part of the door.

Slots were milled to take pre- drilled and partially shaped hinges.

Silver soldered in place and cleaned up, rivets etc were added to finish, then it was tried for size in the embossed smokebox front.

(Yes, these three embossed rivets were on the wrong side.) ^

! I recognised the phone number as it's the next code going East from here, but not the name of the company, must be something to do with my age. I didn't know that he did two versions, though, I'll have to et mine out and have a look at it.

! I recognised the phone number as it's the next code going East from here, but not the name of the company, must be something to do with my age. I didn't know that he did two versions, though, I'll have to et mine out and have a look at it.