One step forward and two steps back as the saying goes.

late last week I added some of the body details including the handrails in the cab doors and tank fronts. For the tank fronts I followed the instructions and the door handrails went into pre etched holes.... or so I thought when re-examining them the following day.

The instructions for the tank front hand rails have a mounting bracket which you bend and solder inside the tan front after filing a recess so that the top of the bracket is level with the top of the tank front. This resulted in the handrail leaning in both planes... So last night I took them off straightened them and then filed them so that when soldered back flat the hand rail was vertical in both planes.

I will take the slight bend out of that one too - blessed close up photos......

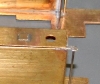

This rather poor shot shows that they are now straight!

One of the holes in the footplate left one of the cab door handrails askew too so that came off and was straightened too.

Tonight's plan is to start assembling some of the sub assemblies.....