Brian McKenzie

Western Thunderer

.........................................9" x 3-1/2" Channel...........................................................................Brass stock...................................8" x 3-1/2".....

First modelling work for 2018, was converting strips of brass into lengths of channel section - to represent scale 9" x 3-1/2" steel channel, plus a couple of lengths made as 8" x 3-1/2".

Wagons, of my 1/48 scale New Zealand Railways prototype, have very distinctive headstocks of steel channel - where the exposed ends show prominently.

The channels were cut by 'flick milling' - a term used by some to describe using a shaped tool in the manner of a fly cutter - most commonly performed using a milling machine's horizontal arbour.

Brass sheet was first sliced into strips to the finished width of the channels.

A pair of steel bars was prepared to support the sides and base of the brass material by cutting a groove along the uppermost edge. Pins were inserted at each end as alignment dowels.

Much effort was expended on grinding the end of short lengths of 5/16" square H.S.S. (lathe turning tool material) for cutting out the internal contour of the channels to show the tapering section of the flanges. This task was made more difficult by endeavouring to additionally trim the flange height at the same time and provide some rounding to the inner edges.

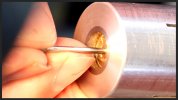

The cutting tool was secured in a small diameter arbour (machining time is usefully speeded up by arranging the tool to have the smallest diameter cutting circle), and carefully centered over the brass bar visually by taking a trial shallow cut.

When all is well, cuts are made at full depth in a single pass - to avoid any collapsing of the thin channel section.

-Brian McKenzie

Last edited:

) appropriate to my scale, are notorious for wandering off line and taking a path of their own, thus spoiling the precision and the finish desired. Yes, the cutting tool used is just like a lathe parting tool. It is mounted to cut in the smallest diameter circle, so that the spindle speed can be increased to take more cuts per minute of feed.

) appropriate to my scale, are notorious for wandering off line and taking a path of their own, thus spoiling the precision and the finish desired. Yes, the cutting tool used is just like a lathe parting tool. It is mounted to cut in the smallest diameter circle, so that the spindle speed can be increased to take more cuts per minute of feed.  And when the slicing cut is just about to finish, a finger was placed on top of the start end, to tip the newly cut strip upwards away from the spinning cutter (it pivoting at the clamp in a see-saw action).

And when the slicing cut is just about to finish, a finger was placed on top of the start end, to tip the newly cut strip upwards away from the spinning cutter (it pivoting at the clamp in a see-saw action).