Dog Star

Western Thunderer

A fellow S7 modeller has asked me to make the track for his LNWR station.... not only is there a lot of track to be built, I have yet to find a straight bit anywhere on the templates. The construction of the layout is covered in the thread "Hartley Hills - LNWR circa 1910".

Trackmaking is easy, almost like building a plastic kit in 2D. OK, there is the small matter of setting out the line and purchasing / making of templates and that can be time-consuming, however getting sleeper and timber positions on paper is not difficult so we can start. There are several suppliers of consumables for 7mm track making including Slaters, Exactoscale, C&L and Peco - there may be others, those are the companies which are known to me. Each of those suppliers offers rail, chairs and sleepers - my preference is for Exactoscale products from whom I buy ABS chairs and ply sleepers. I have used C&L chairs and I find that the Exactoscale parts are more consistent in performance.

There is a pile of small plastic mouldings beside a stack of cut-to-size trees on the workbench, what next? As a minimum track making needs a method of setting the rails to gauge and of doing so in a repeatable and consistent manner. Enter the track gauges, preferably a few of the gauge for plain track so that several chairs can be affixed at a time, thankfully one of the check rail gauges ought to do. Unless you are modelling a section of the railway across an Australian desert then you will need to consider diverging rails and that means turnouts. Exactoscale and C&L supply some machined /assembled parts for switches and crossings or you can make your own, the price of one set of machined parts is comparable to the price of one Vee filing jig (S7 Group Stores)... so buy a jig and practice the art.

I have built several turnouts and quite a length of plain track over the past few years and repetitive tasks soon become boring - jigs for reducing the time to perform such tasks more than pay for the initial effort taken to make such fixtures. Paul Penn-Sayers (Locomodels on this forum) has been most helpful in taking my initial suggestions and producing something which reaps rewards - some of his works appears in my following posts, watch out for the check chair cutting jig, the rail cutting jig and the timber cutting jig.

I have written other topics and/or threads about my track making escapades (here, elsewhere and "over there") where those writings are about the result rather than the method. In those posts I have often mentioned the jigs and gauges which are available from the S7 Group Stores, the availability of such items is covered in another thread. A recent conversation with another WT member suggested to me that maybe a description of such jig and gauges would be of interest.

As there is much to cover I shall write and post this topic in several parts:-

[1] jigs and gauges for building small quantities of permanent way;

[2] jigs for plain line track;

[3] jigs for those who are about to build Kings Cross or Paddington or Basilica Fields.

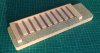

To start, a photograph of the range of jigs and gauges which I use regularly.

Tracks and Gauges

Vee filing and assembly jigs to top LHS, crossing assembly jigs to bottom RHS, check chair cutting jig to top centre, check rail gauge to top RHS and sprung track gauge to centre RHS.

Vee filing and assembly jig

The bottom jig shows the face which is used to file the tapers on the point/splice rails, to form the wing rail and to hold the vee during soldering. The top jig shows the face which is used to file the housing, in the point rail, for the splice rail. The plate and screw to the RHS is the clamp plate which holds the rails whilst filing the tapers and housing. The lower jig is marked "1 - 7" for making a vee of 1:7 angle.

Common crossing assembly jig- 1

The top jig, in paxolin, shows the slots for holding the vee and the two wing rails of a common crossing. The jig can be used also for creating the obtuse crossing of compounds and diamonds. The bottom jig, in Aluminium, shows how the separate rails are loaded into the jig and then secured into a common crossing by brass strips. Whilst the S7 Group manufactured the assembly jigs in Aluminium originally the current products are made in paxolin (easier to solder rails in paxolin jigs than rails in Aluminium jigs).

Common crossing assembly jig - 2

The top jig, in Aluminium, shows how the metal is machined to form the spacing strips which hold the wing rails and vee at the correct separation. Underneath the jig is the same common crossing as in the previous photograph, this time showing the head of the rail.

Track gauges

The left hand gauge is for setting the check rails, check rails are gauged from the common crossing - hence the need for the flat on the outer edge of the gauge, the flat rests on the vee of the crossing when gauging check rails. The right hand gauge is for setting the "track gauge", 33mm in the case of S7 track. My track gauges have been modified by Paul Penn-Sayers (Locomodels on this forum)... the outer washers have been turned with a 1:20 taper so that the gauges hold the rails at an angle which matches the chair mouldings. I understand that S7 Group Stores may be about to supply these gauges with the same modification.

Check chair cutting gauge

A simple cutting gauge which was developed by Paul Penn-Sayers - the photograph shows the prototype jig and is the basis of a recent "how to make" article in the S7 Newsletter. The upright strip of metal forms a fence to facilitate cutting a plain line chair - the metal thickness is half of the scale dimension for the check rail clearance. A plain line chair is threaded onto a piece of rail and then pushed through the hole in the upright. The part of the chair which protrudes through the fence is then cut off. One of the cut chairs is put on the running rail, one of the cut chairs is put on the check rail.... and then the cut chair on the check rail is placed against the cut chair on the running rail. A splash of Butanone joins the chairs and the rails are held at the correct separation for S7.

regards, Graham

Trackmaking is easy, almost like building a plastic kit in 2D. OK, there is the small matter of setting out the line and purchasing / making of templates and that can be time-consuming, however getting sleeper and timber positions on paper is not difficult so we can start. There are several suppliers of consumables for 7mm track making including Slaters, Exactoscale, C&L and Peco - there may be others, those are the companies which are known to me. Each of those suppliers offers rail, chairs and sleepers - my preference is for Exactoscale products from whom I buy ABS chairs and ply sleepers. I have used C&L chairs and I find that the Exactoscale parts are more consistent in performance.

There is a pile of small plastic mouldings beside a stack of cut-to-size trees on the workbench, what next? As a minimum track making needs a method of setting the rails to gauge and of doing so in a repeatable and consistent manner. Enter the track gauges, preferably a few of the gauge for plain track so that several chairs can be affixed at a time, thankfully one of the check rail gauges ought to do. Unless you are modelling a section of the railway across an Australian desert then you will need to consider diverging rails and that means turnouts. Exactoscale and C&L supply some machined /assembled parts for switches and crossings or you can make your own, the price of one set of machined parts is comparable to the price of one Vee filing jig (S7 Group Stores)... so buy a jig and practice the art.

I have built several turnouts and quite a length of plain track over the past few years and repetitive tasks soon become boring - jigs for reducing the time to perform such tasks more than pay for the initial effort taken to make such fixtures. Paul Penn-Sayers (Locomodels on this forum) has been most helpful in taking my initial suggestions and producing something which reaps rewards - some of his works appears in my following posts, watch out for the check chair cutting jig, the rail cutting jig and the timber cutting jig.

I have written other topics and/or threads about my track making escapades (here, elsewhere and "over there") where those writings are about the result rather than the method. In those posts I have often mentioned the jigs and gauges which are available from the S7 Group Stores, the availability of such items is covered in another thread. A recent conversation with another WT member suggested to me that maybe a description of such jig and gauges would be of interest.

As there is much to cover I shall write and post this topic in several parts:-

[1] jigs and gauges for building small quantities of permanent way;

[2] jigs for plain line track;

[3] jigs for those who are about to build Kings Cross or Paddington or Basilica Fields.

To start, a photograph of the range of jigs and gauges which I use regularly.

Tracks and Gauges

Vee filing and assembly jigs to top LHS, crossing assembly jigs to bottom RHS, check chair cutting jig to top centre, check rail gauge to top RHS and sprung track gauge to centre RHS.

Vee filing and assembly jig

The bottom jig shows the face which is used to file the tapers on the point/splice rails, to form the wing rail and to hold the vee during soldering. The top jig shows the face which is used to file the housing, in the point rail, for the splice rail. The plate and screw to the RHS is the clamp plate which holds the rails whilst filing the tapers and housing. The lower jig is marked "1 - 7" for making a vee of 1:7 angle.

Common crossing assembly jig- 1

The top jig, in paxolin, shows the slots for holding the vee and the two wing rails of a common crossing. The jig can be used also for creating the obtuse crossing of compounds and diamonds. The bottom jig, in Aluminium, shows how the separate rails are loaded into the jig and then secured into a common crossing by brass strips. Whilst the S7 Group manufactured the assembly jigs in Aluminium originally the current products are made in paxolin (easier to solder rails in paxolin jigs than rails in Aluminium jigs).

Common crossing assembly jig - 2

The top jig, in Aluminium, shows how the metal is machined to form the spacing strips which hold the wing rails and vee at the correct separation. Underneath the jig is the same common crossing as in the previous photograph, this time showing the head of the rail.

Track gauges

The left hand gauge is for setting the check rails, check rails are gauged from the common crossing - hence the need for the flat on the outer edge of the gauge, the flat rests on the vee of the crossing when gauging check rails. The right hand gauge is for setting the "track gauge", 33mm in the case of S7 track. My track gauges have been modified by Paul Penn-Sayers (Locomodels on this forum)... the outer washers have been turned with a 1:20 taper so that the gauges hold the rails at an angle which matches the chair mouldings. I understand that S7 Group Stores may be about to supply these gauges with the same modification.

Check chair cutting gauge

A simple cutting gauge which was developed by Paul Penn-Sayers - the photograph shows the prototype jig and is the basis of a recent "how to make" article in the S7 Newsletter. The upright strip of metal forms a fence to facilitate cutting a plain line chair - the metal thickness is half of the scale dimension for the check rail clearance. A plain line chair is threaded onto a piece of rail and then pushed through the hole in the upright. The part of the chair which protrudes through the fence is then cut off. One of the cut chairs is put on the running rail, one of the cut chairs is put on the check rail.... and then the cut chair on the check rail is placed against the cut chair on the running rail. A splash of Butanone joins the chairs and the rails are held at the correct separation for S7.

regards, Graham

Last edited:

It was some years ago when I was in Dick's workshop and saw the setup and I began to think that things might have changed since then.

It was some years ago when I was in Dick's workshop and saw the setup and I began to think that things might have changed since then.