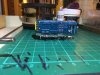

It’s time for an update. First on Gronk One, the 08: silly me thought the chassis was coming along nicely, but when test power was applied it became clear that something was amiss, and the harder I looked, the more amiss things became. I stripped the whole lot out and I soon saw that the gearbox was twisted, the motor shaft was pointing diagonally across the length, and when I took the driven wheels out, one of the bearings come out too. So I ordered up some new bearings, straightened everything out and soldered some scrap etch onto the back of the gearbox part of the frames to stiffen it up a little. The new bearings went on and the gears and wheels reassembled. Now another issue appeared, the worm gear was occasionally catching the underside of the overhanging gearbox frame, so everything came back out and some filing saw off the offending metal. So as of now, I have a free running and square mechanism ready for quartering, putting the motor back on, Simpson spring renewal where needed and then we’ll be back where this update started....

I have also progressed with the Presflo wagon, slowly, the best news here being that the carpet monster today gave back the vacuum cylinders that were recently lost. Tip of the day, when vital components vanish into the pile, lift the edge up and give it a good beating, it soon coughs then back out! Only works on rugs of course, don’t try pulling up the fitted Axminster. Thanks to Gilly for her persistent searching that revealed the partstoday.

There is also a BR brake van progressing nicely which is also benefiting from improved soldering with the tiny balls of solder.

The mk1 is on hold for now until I sort out the remaining parts for the underframe.

Cheers for now.

John

Recording progress as it occurs...

Recording progress as it occurs...