Tim Watson

Western Thunderer

A real race horse.

Tim

Tim

Most people pick up locos by grabbing the main driving wheels which runs the risk of the footplate deforming between thumb and fingers.

If any WTers see me playing with my engines, come and say hello. It's always good to put faces to names.

Cheers,

Peter

Hi Peter,

I will be a long so I will look out for you at the test track

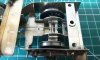

That's a fine looking thoroughbred there. Although as usual the camera is a cruel mistress - one small query in the last photo the middle boiler band in front of the dome doesn't look quite seated against the boiler.So from a detail point of view, that just leaves the cab glazing and sight screens to be added after painting. I now need to order the motor/gearbox from ABC and add the pick ups.

That's a fine looking thoroughbred there. Although as usual the camera is a cruel mistress - one small query in the last photo the middle boiler band in front of the dome doesn't look quite seated against the boiler.

Excellent. I can see that I shall have to go over mine (again!) before painting to add a few of the details you have included. Things like the injectors and the beefing up of the vacuum cylinder crank to piston joints. All those little bits really add to the overall effect.

Richard