Onward, the final rigid bearing was swapped out for a sprung unit and the axle boxes tested and fitted.

I already know getting the engine springs off or making them removable is hard work; plus making the brake gear also removable is just prone to damage so the axle boxes are permanently retained. You can still just get the wheels off if required.

I've allowed an axle box travel of around 1 - 1.5 mm which should cater for most eventualities.

One of the down sides to the sprung units is that they are all inside the frames. The real engine has narrow frames so that they sit on top of the axle boxes mid axis.

This means that on the model there is a large gap between the axle box face and inside wheel face.

In short you have to find spacers to fill at least 2.75 mm (O fine) each side to reduce lateral play. The kit only provides three washers for each axle, a 0.7, 0.45 and 0.225 mm which still leaves 1.375 mm to find. Fortunately having used sprung units you now have six top hat bearings spare, the flange being 1.55 mm thick. You need to cut the flange off and add the 0.7 + 0.225 washers to give 2.475 mm spacing.

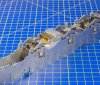

From left to right, 0.225, 0.7, top hat flange 1.55 mm. I've kept the top hat bearing stubs (above and below flanges) as they may come in useful at some point.

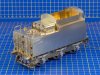

Once all the wheels and washers are added you end up with this.

You should end up with about 0.25 mm play left and right, the reality is a little greater, more like 0.4 mm. If you think you need more then drop out the 0.225 or swap the 0.7 for the spare 0.45.

Setting the wheel height is in the instructions, essentially it's 43.75 mm from rail head to top of the frames. In the above instance the wheels are at maximum deflection downward and the rims are just level with the tops of the frames; when fully compressed the rim should be above the frames, but the tyre should not, as a rule of thumb.

The wheels look higher here, but that's due to the gap twixt frame and wheel giving that impression.

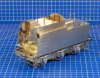

Finally, one of the first etches I did for Finney7 were overlays for the Slaters Bullied wheels, there's nowt wrong with them out of the box, but the depressed front face is a touch too much, as is the step between the rim and front face. The front face is also raised at the hub and slopes toward the rim so I will gently ease the centre up away from the wheel to mimic that later.

At the moment the etch is flat and the boss looks too high, it needs to be half that height.

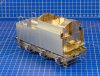

The massive gap where the oil bath should be is evident and I'll knock up a simple fold up light blocker here.

.

.

.

.

) - M&GN Class A tank (C17). - Damn Dave beat me to it!!

) - M&GN Class A tank (C17). - Damn Dave beat me to it!!

.

.

I'll have a couple of spare cab sides left over, available at cost + P&P for anyone else who's had CCU make an appearance on their 64xx. I still need to add the firebox top etch and the tank top has been altered to suit that variant with a wider opening for the firebox top.

I'll have a couple of spare cab sides left over, available at cost + P&P for anyone else who's had CCU make an appearance on their 64xx. I still need to add the firebox top etch and the tank top has been altered to suit that variant with a wider opening for the firebox top.