richard carr

Western Thunderer

I recently purchased a 6 pack of MMP catfish wagons. By the Musty smell of the packaging I fear that Dave P hasn't sold many of these recently.

Simon Varnam has one of these on his website so if you are going to try I recommend that you take a look, there is a lot of useful information there.

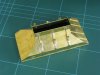

Anyway I have spent the past week working in Chicago and took 1 of them with me. After spending 6 hours removing parts from the etch and cleaning them up, this is what I ended up with.

Not that I want to get started on a whinge but the parts are vary firmly attached to the etch and a large part probably about 3-4 hours was spent cutting parts from the etch and then filing off the remains of the tabs, I'm sure you could get away with half the number of tabs that has been used for a lot of the parts and save a several hours from the build of hours. So Dave P is you are reading this please note for your future kits.

You don't really need that many tools to build these, so good files are the main ones, especially a barrette file (the one that has angled in sides and comes to a point so that you get into triangular areas) I have large 4th cut vallorbe one and a couple of smaller needle files. The other key tools are a piece of wood to cut the parts out on and a sharp knife. I have used an 80 watt soldering iron for all the soldering done here.

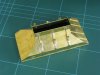

Now to the good bit I have spent about 4 hours this weekend soldering these bits up, its been a delight, the fit of the parts is near PERFECT, here are the results

The detail in the hopper is tremendous and every part has fitted so well together, there is no need for any bodging here. There is still quite a lot of work to do on the hopper.

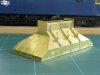

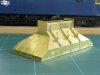

Here is the chassis

The design thought behind the kit is excellent, you could easily think that soldering the leaf spring supports would be a nightmare to get in the right place, but no, there is a tiny little lug on each one that fits into the one that comes W iron and gets everything lined up perfectly. This just what you want from a well designed kit.

One thing you do need to note that through out the kit lots of parts are handed so sometimes it worth writing the part number on the part itself with a marker pen. you can see a few of these in the photos.

I'm heading back to do some more now, this is one kit I don't want to put down.

Simon Varnam has one of these on his website so if you are going to try I recommend that you take a look, there is a lot of useful information there.

Anyway I have spent the past week working in Chicago and took 1 of them with me. After spending 6 hours removing parts from the etch and cleaning them up, this is what I ended up with.

Not that I want to get started on a whinge but the parts are vary firmly attached to the etch and a large part probably about 3-4 hours was spent cutting parts from the etch and then filing off the remains of the tabs, I'm sure you could get away with half the number of tabs that has been used for a lot of the parts and save a several hours from the build of hours. So Dave P is you are reading this please note for your future kits.

You don't really need that many tools to build these, so good files are the main ones, especially a barrette file (the one that has angled in sides and comes to a point so that you get into triangular areas) I have large 4th cut vallorbe one and a couple of smaller needle files. The other key tools are a piece of wood to cut the parts out on and a sharp knife. I have used an 80 watt soldering iron for all the soldering done here.

Now to the good bit I have spent about 4 hours this weekend soldering these bits up, its been a delight, the fit of the parts is near PERFECT, here are the results

The detail in the hopper is tremendous and every part has fitted so well together, there is no need for any bodging here. There is still quite a lot of work to do on the hopper.

Here is the chassis

The design thought behind the kit is excellent, you could easily think that soldering the leaf spring supports would be a nightmare to get in the right place, but no, there is a tiny little lug on each one that fits into the one that comes W iron and gets everything lined up perfectly. This just what you want from a well designed kit.

One thing you do need to note that through out the kit lots of parts are handed so sometimes it worth writing the part number on the part itself with a marker pen. you can see a few of these in the photos.

I'm heading back to do some more now, this is one kit I don't want to put down.

)

)