P A D

Western Thunderer

Well now that the Finney A3 is done for now, it's time to move onto the next build. I know there have been a few builds of this kit on various forums since its introduction, but here's my two penn'orth.

First a looks at what's in the box. Here are the myriad of castings and the Slaters wheels.

And the etchings.

And very extensive and profusely illustrated instructions. There are a whole host of prototype photos of 80002 in the running shed at Howarth, but I've also been up to Oxenhope where it is now stored out of use and taken pot loads more. I even got permission to climb up onto the running plate and take some shots of the tank tops and also in the cab.

Cast part identification.

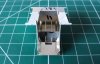

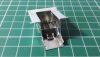

And finished already!

Only joking of course. This is the DJB one I built for my brother some years ago, so it will be good to compare and contrast the two. It's a pity the running plate above the cylinders is too low, but I knew that at the time and decided to leave it. I wish I'd set it in forward gear though.

Cheers,

Peter

First a looks at what's in the box. Here are the myriad of castings and the Slaters wheels.

And the etchings.

And very extensive and profusely illustrated instructions. There are a whole host of prototype photos of 80002 in the running shed at Howarth, but I've also been up to Oxenhope where it is now stored out of use and taken pot loads more. I even got permission to climb up onto the running plate and take some shots of the tank tops and also in the cab.

Cast part identification.

And finished already!

Only joking of course. This is the DJB one I built for my brother some years ago, so it will be good to compare and contrast the two. It's a pity the running plate above the cylinders is too low, but I knew that at the time and decided to leave it. I wish I'd set it in forward gear though.

Cheers,

Peter