P A D

Western Thunderer

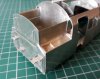

For an old kit the DJB does not look bad at all.

Hi Peter,

Yes the DJB kit was very good for it's time. All nickel silver etching very good white metal and nickel castings. Price wise if I remember corrctly, it was on the expensive side and I was only able to afford it on the back of a long service award from the company I worked for. It now belongs to my brother and he's getting pd off as I keep pointing out it's shortcomings.

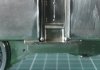

If it was still around now, the MOK would be the better option. The DJB one is too wide at the fire box, too wide at the bunker which does not taper and the running plate at the smoke box is too low over the cylinders. There are no driving wheel springs and it has taken me until last week at the Doncaster show to get some castings from Ragstone. The cab interior is very detailed although the are no seats. The roof was soldered in place before painting and the back plate and floor are added from underneath and screwed in.

I think running on a layout it would pass muster against the MOK version, unless srutinised closely when next to each other. The most stand out difference being the low running plate. If you spotted an untouched kit at a good price it would worth a punt.

these MOK kits are a miracle. One day, I want to build one. A little practicing will be needed first

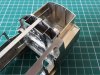

I enjoy watching how the shape forms from the etches. Almost like real loco building.

Michael

Hi Michael,

If you've built a few etched kits, particularly with outside valve gear, these kits are not that difficult. When I looked at the parts in the box and opened the instructions the first time, it looked very daunting, even having over 30 years experience building etched kits. However, once you get started it is a lot easier than it looks and you start to realise why these and the Finney 7 kits are so expensive.

If you get stuck, Dave Sharp at MOK is only a phone call away and he is extremely helpful. Also the advantage these day is that with forums like these, you can usually find a build by somebody else, which I always find useful. For the 4MT I have photos from 2 other builders that I can refer to, and also there are so many talented builders on here that you can always get help when needed. Even the professional builders and painters are willing to help and will always answer your questions.

Cheers,

Peter

Cough! Trammel...?

Cough! Trammel...?