And now with wheels

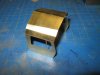

Tried something different here, CSB in as basic a format as I could, no fancy hornblocks guides or what ever, just slots and top hat bearings, whether it'll stand the test of time will be another matter but thus far it ticks all the boxes in that there's little side play, up and down movement is free, it's simple and it's cheap.

First task is to stick the bearings to a piece of 25 thou brass with double sided tape.

Next stick in vice and file a slot where you want the CSB tube to go

Apply tube in one whole length and solder profusely

Cut each individual bearing off and retain as much of the tube as you wish, I kept as much as possible working on the theory that the tube will just touch the inside of the frames and stop the bearing moving out, in hindsight there's no need as side play is determined by frame spacing and wheels/top hat bearing flange.

I've opted for under slung as over slung will be seen through the large slots at the top of the axleboxes on the 1:1 frames. In theory the longer CSB tubes at the base of the top hat bearing should stop it rotating, it'll rotate a little but not round and round.

Seems to sit right and rock in all the right places, I may need to fiddle with the position of the intermediate tubes to get the balance right as at the moment it's best guess. On the 08 I followed the spreadsheets and found the loco still rocked about the centre axle (even though it was 10% less than those either side) so ended up moving the intermediate fixings to suit by reducing the % load on the intermediate axle even more.

I finally did the firebox shoulders, initially dreading the very large radius I'd seen in photos, however before taking the plunge I decided to visit the image store once more and noticed a loco whose shoulder radius was virtually non existent, very Fowler square style radiused corners, further investigation reveals two major types of sheet metal work on the firebox shoulders, those with very large radius and those with virtually none, there is a third which seems sort of between the two but edging more toward the smaller radius. I've no idea why there are differing types, a quick look at other BR types find them all to be the same through out the class...which ever style they have. It's not just one or two locos either, I've over 40 photos of the smaller sharper radius fireboxes....of course I've opted for one of these, which means in due course there will be much finger pointing by those that proclaim to know better

F105-022

F105-022 by

vsidlow, on Flickr

F040-148

F040-148 by

vsidlow, on Flickr

Above has the small radius firebox shoulder as compared to below with the large

It would appear that you stand a higher % of having the smaller radii if it's a Southern or Scottish loco but I've seen locos at Crewe/WCML and York with the smaller Radii. On hindsight I've probably added to much radius to mine so it's more toward the intermediate style.

, looks like you would have to live near it as it would take a long time to see it finished.

, looks like you would have to live near it as it would take a long time to see it finished. but like the taper boiler will probably not be the chore I'm dreading, it'll be a slowly slowly catchy monkey process though LOL

but like the taper boiler will probably not be the chore I'm dreading, it'll be a slowly slowly catchy monkey process though LOL

I'm sure they are very helpful if contacted and will answer all questions accurately, it'd just be nice if you could glance down the list and see without recourse to bothering them with fundamental questions as to some basics about the wheel.

I'm sure they are very helpful if contacted and will answer all questions accurately, it'd just be nice if you could glance down the list and see without recourse to bothering them with fundamental questions as to some basics about the wheel.

out of me already.

out of me already.