Heather Kay

Western Thunderer

The thread title will make sense when I explain this build is an Austerity 2-8-0, and the client's chosen loco ended its days at Aintree 27B.

This commission build is of the JLTRT WD kit. It's a mixed media kit, with the usual mix of resin, etched and cast metal. Forgive me for not photographing the unbuilt parts - the bench is in a bit of a mess, and I was not in the mood to clear it.

The loco to be built is 90643, and the client wants to weather it. The build, therefore, will be to ex-works standards. Happily, the client found photos of the loco from both sides, so I can get most of the specific details right.

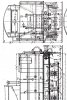

The box that arrived contained several spare sets of frame etches. I have a feeling a previous owner began the build, then found it beyond their skills. I know the client felt he couldn't do the build justice, which is where I stepped in. A nice weighty resin boiler assembly, with a resin smokebox saddle, sits on nickel silver frames and brass running plate and cab. Large whitemetal castings for the backhead and boiler fittings, with some frankly beautiful lost wax brass detail castings. I seem to have the super detail kit, which is nice. The tender has a nickel silver inside frames and a compensation system, brass running plate, front and fenders, with the main body cast in resin. Lots of nice brass castings replicate the brakes, suspension and axle boxes.

I have decanted the castings into a couple of plastic boxes, engine and tender. Standard Slater's wheels and a GB30R-3M gearbox with Mashima 1833 completes the mechanicals. Happily, no DCC or sound is required. I'm going to have to cross that bridge one day.

Needing a break from the MMP RMB build, I picked this box off the shelf. I made a start on the tender, and this is the result after about half a day at the bench. As ever, the instructions don't quite match the box contents, so I'm have to dig into my resources a bit. One thing exercising me right now is how to fit the bunker internal bracing. It's in the etch, but not mentioned in the instructions. I really need some clear photos of an empty bunker from above, so I feel a spot of armchair modelling coming on.

This commission build is of the JLTRT WD kit. It's a mixed media kit, with the usual mix of resin, etched and cast metal. Forgive me for not photographing the unbuilt parts - the bench is in a bit of a mess, and I was not in the mood to clear it.

The loco to be built is 90643, and the client wants to weather it. The build, therefore, will be to ex-works standards. Happily, the client found photos of the loco from both sides, so I can get most of the specific details right.

The box that arrived contained several spare sets of frame etches. I have a feeling a previous owner began the build, then found it beyond their skills. I know the client felt he couldn't do the build justice, which is where I stepped in. A nice weighty resin boiler assembly, with a resin smokebox saddle, sits on nickel silver frames and brass running plate and cab. Large whitemetal castings for the backhead and boiler fittings, with some frankly beautiful lost wax brass detail castings. I seem to have the super detail kit, which is nice. The tender has a nickel silver inside frames and a compensation system, brass running plate, front and fenders, with the main body cast in resin. Lots of nice brass castings replicate the brakes, suspension and axle boxes.

I have decanted the castings into a couple of plastic boxes, engine and tender. Standard Slater's wheels and a GB30R-3M gearbox with Mashima 1833 completes the mechanicals. Happily, no DCC or sound is required. I'm going to have to cross that bridge one day.

Needing a break from the MMP RMB build, I picked this box off the shelf. I made a start on the tender, and this is the result after about half a day at the bench. As ever, the instructions don't quite match the box contents, so I'm have to dig into my resources a bit. One thing exercising me right now is how to fit the bunker internal bracing. It's in the etch, but not mentioned in the instructions. I really need some clear photos of an empty bunker from above, so I feel a spot of armchair modelling coming on.

Last edited:

as well as a whole load of others book marked for purchase

as well as a whole load of others book marked for purchase