You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm On Heather's Workbench - North Western Commuter Power

- Thread starter Heather Kay

- Start date

Heather Kay

Western Thunderer

It’s been a week of medical things, for both Best Beloved and myself, not to mention that other elephant in the room that’s been making its presence felt. This has meant, variously, that the mojo has been lacking. This also happens when there is a need for metalbashing, fire and various shaping tools.

The boiler is supplied already rolled, and needs just soldering together. It’s round enough for the purposes of model locos, at least. As the loco in question had the superheated boiler with Belpaire firebox, I didn’t need to add a smokebox overlay, but I did need to form the firebox. Plenty of fun with the gas torch followed. I used the rear former as my shape guide. The first effort ended up being undone and flattened out. The second attempt is as good as I can make it. I guess the next job, then, is to make up the firebox. I shall run some copper wire round the inside of the joins for reinforcement. The front one will also allow me some leeway for filing a radius on the front corners - I’ll check the references first as I don’t expect it’ll be a nice rounded job as later Belpaire boxes had.

The smokebox front ring can go in, too. Then I can think about making up a saddle that clears the valve rods properly.

I really need to get some more reference study done as it’s approaching the time to start adding detail.

Heather Kay

Western Thunderer

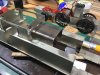

I was doing a test fit of the boiler bits on the chassis and footplate. I found I had a problem with the reversing lever. Paul had temporarily fixed it in what amounts to "neutral", knowing it may need to be set to a suitable angle when the bodywork went on.

Well, I’ve been gently rolling the frames back and forth, holding the lever at various angles that will hopefully clear the boiler barrel. It’s slightly hypnotic, watching everything move about! This has, however, thrown up a couple of questions.

The first is concerning the position of the lever for full forward or reverse gear. The loco had screw reversing, so I am tempted to assume that full reverse would pull the lever towards the cab, and vice verse for forward gear. If any of WT's L&Y devotees are reading this, perhaps they might be able to confirm my assumption.

(Of course, in an ideal world, the gear would be set according to which direction has been selected on the layout controller. That, however, is a fair way beyond my ken, and would add several layers of complexity I am not even comfortable thinking about.)

The second question concerns weight. I found the gear slightly sticky in full forward or reverse, until I applied pressure to compress the suspension. I ponder, therefore, how much extra weight I should need to add to this model. I don’t want to overdo it, as I understand service life isn’t likely to be particularly arduous. There isn’t a whole lot of space available for extra weight, either, allowing for later fitting of electronics for sound and control. Ballast could go in the side tanks, and the boiler, and some could be squeezed into the bunker. I haven’t allowed for all the castings to be fitted yet, of course, but some pointers would be appreciated.

Yes, I have noticed one of the motor leads has come off the pickup.

Heather Kay

Western Thunderer

I thought I had the firebox sorted out, but it’s nowhere near. I’ve battered it flat again, but I think it’s too far gone now. Time to think about scratching something.

Not only that, the smokebox door casting doesn’t fit the boiler barrel.

I might just take up something simpler, like sheep farming in Barnet.

Not only that, the smokebox door casting doesn’t fit the boiler barrel.

I might just take up something simpler, like sheep farming in Barnet.

Heather Kay

Western Thunderer

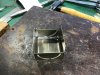

One thing about the kit firebox was the washout plugs were not really right. As part of creating a firebox from scratch, it made sense to sort that out as well.

Raw materials. I’m going to need to get some more of that NS sheet soon. It’s turning out to very useful. The battered and bruised kit part will give me some essential dimensions, and the Bits Box coughed up cast washout plugs.

I got a bit carried away and started marking out on the metal. Then I realised I really ought to work out exactly where the washout plugs went.

I found a photo in the references which, handily, was taken exactly side on to the fireman's side of a loco. All I needed was some back of an envelope calculations to give me a ratio that would let me convert the photo dimensions to scale dimensions. I would be happy to be within a couple of scale inches, to be honest.

Don’t laugh. The ratio turned out to be as near as damn it 77.5. 64 inches is the guesstimated length of the firebox from the kit part, not allowing for the rounded front corners. The tick marks along the top edge are key points from the photo. This gave me the first plug from the cab on the fireman's side at 3.5mm. A little further calculator stabbing and I found the plug spacing was probably 18 inches on the real thing.

Best Beloved suggested a paper model might be worth creating before committing to metal. Sensible man.

Here's the shape I need to match. The knotty bit for my brain cell was working out where the centre of the radius corners was, so an element of trial and error followed. It’s obvious to almost everyone else it’s 45 degrees around, using the boiler centre. Maths and allied trades are not one of my strong points, I readily admit. On to the CAD.

That is, as regular followers of my antics will know, Cardboard Aided Design. Pleased with that. I’ve added some extra depth to the sides, in order to make fitting to the tanks easier. Further photo peering showed me the plugs on the other side are pretty much centred on the box, so the offset was easy to work out.

I suppose it’s now time for some metal bashing.

Raw materials. I’m going to need to get some more of that NS sheet soon. It’s turning out to very useful. The battered and bruised kit part will give me some essential dimensions, and the Bits Box coughed up cast washout plugs.

I got a bit carried away and started marking out on the metal. Then I realised I really ought to work out exactly where the washout plugs went.

I found a photo in the references which, handily, was taken exactly side on to the fireman's side of a loco. All I needed was some back of an envelope calculations to give me a ratio that would let me convert the photo dimensions to scale dimensions. I would be happy to be within a couple of scale inches, to be honest.

Don’t laugh. The ratio turned out to be as near as damn it 77.5. 64 inches is the guesstimated length of the firebox from the kit part, not allowing for the rounded front corners. The tick marks along the top edge are key points from the photo. This gave me the first plug from the cab on the fireman's side at 3.5mm. A little further calculator stabbing and I found the plug spacing was probably 18 inches on the real thing.

Best Beloved suggested a paper model might be worth creating before committing to metal. Sensible man.

Here's the shape I need to match. The knotty bit for my brain cell was working out where the centre of the radius corners was, so an element of trial and error followed. It’s obvious to almost everyone else it’s 45 degrees around, using the boiler centre. Maths and allied trades are not one of my strong points, I readily admit. On to the CAD.

That is, as regular followers of my antics will know, Cardboard Aided Design. Pleased with that. I’ve added some extra depth to the sides, in order to make fitting to the tanks easier. Further photo peering showed me the plugs on the other side are pretty much centred on the box, so the offset was easy to work out.

I suppose it’s now time for some metal bashing.

Heather Kay

Western Thunderer

Dave Holt

Western Thunderer

Heather,

You are correct in assuming that Joy valve gear has the curved guides sloping forward for forward gear and back wards for reverse. Of course, a loco would only be put into full gear to start away or at very low speeds, so perhaps somewhere about half way between full and mid gear would be a reasonable position, assuming the reversing crank misses the boiler on that position.

Such a position may also overcome the slight sticking whilst being less critical on the suspension compression?

A very impressive project to have working Joy gear, in my opinion. I have been looking at ways of doing it in P4 for a Class 27 0-6-0.

Dave.

You are correct in assuming that Joy valve gear has the curved guides sloping forward for forward gear and back wards for reverse. Of course, a loco would only be put into full gear to start away or at very low speeds, so perhaps somewhere about half way between full and mid gear would be a reasonable position, assuming the reversing crank misses the boiler on that position.

Such a position may also overcome the slight sticking whilst being less critical on the suspension compression?

A very impressive project to have working Joy gear, in my opinion. I have been looking at ways of doing it in P4 for a Class 27 0-6-0.

Dave.

Heather Kay

Western Thunderer

Looks like a bit of a challenging kit x scratch build Heather. Looking good though.

It has its moments, but it’s not that bad. I’m fussy, and like to try and get it right if I can.

Heather,

You are correct in assuming that Joy valve gear has the curved guides sloping forward for forward gear and back wards for reverse.

Dave, thank you. As you say, I shall try and fix the gear slightly forward of centre. I should be able to file a bit off the back of the lever as well, which should help a bit.

The front and rear formers are in place.

I’ve installed some thick copper wire inside the front, and filleted some Carr’s 145 solder around it. Fingers crossed I’ll be able to form the radiused corners satisfactorily.

Baby steps. For various reasons, I find this a way to make progress, albeit sluggish. I hope to have a clear week ahead, so the pace really ought to pick up again.

Heather Kay

Western Thunderer

Heather Kay

Western Thunderer

I’m sure, sometimes, I am really losing my marbles.

The kit covers both round top and Belpaire boiler, short and long bunker, superheated, blah-blah-blah. Alternative parts are supplied, such as chimneys and smokebox doors.

I’ve been struggling for a while now trying to reconcile the supplied smokebox door to suit the Belpaire boiler with what it’s supposed to actually look like.

This is what the loco's "face" is supposed to look like.

An etched ring goes into the front of the boiler barrel, and the door fitted to it. The first problem I had is the back of the door casting won’t go in the etched hole. The plug is way too big … and then I noticed the door is way too big. It’s essentially the same diameter as the boiler. There is a distinct lack of extra ring round the outside. Oh, and where is the hinge detail?

Well, a whitemetal hinge rod is provided, and buried in the etches is a plate to represent the door attachment, but that doesn’t get over the door being too big.

Anyway, here is the door intended for the round top boiler. Hmm. Aside from the handle hole in the middle, it fits nicely.

And then I remembered a sprue of cast door dogs in the box. I think I have a solution to the problem. It’s not as simple as plugging the cast door in place, but beggars can’t be choosers. That’s the afternoon sorted, then.

I’ve yet to get to grips with the smokebox saddle, which may be some time yet. I need to spend a good deal of time studying photos, as it doesn’t look as simple as the original cast lump might imply.

The kit covers both round top and Belpaire boiler, short and long bunker, superheated, blah-blah-blah. Alternative parts are supplied, such as chimneys and smokebox doors.

I’ve been struggling for a while now trying to reconcile the supplied smokebox door to suit the Belpaire boiler with what it’s supposed to actually look like.

This is what the loco's "face" is supposed to look like.

An etched ring goes into the front of the boiler barrel, and the door fitted to it. The first problem I had is the back of the door casting won’t go in the etched hole. The plug is way too big … and then I noticed the door is way too big. It’s essentially the same diameter as the boiler. There is a distinct lack of extra ring round the outside. Oh, and where is the hinge detail?

Well, a whitemetal hinge rod is provided, and buried in the etches is a plate to represent the door attachment, but that doesn’t get over the door being too big.

Anyway, here is the door intended for the round top boiler. Hmm. Aside from the handle hole in the middle, it fits nicely.

And then I remembered a sprue of cast door dogs in the box. I think I have a solution to the problem. It’s not as simple as plugging the cast door in place, but beggars can’t be choosers. That’s the afternoon sorted, then.

I’ve yet to get to grips with the smokebox saddle, which may be some time yet. I need to spend a good deal of time studying photos, as it doesn’t look as simple as the original cast lump might imply.

Peter Cross

Western Thunderer

The number of kits I've built with the wrong smokebox door, is high. I think my worst was a Maunsell S15 which only had a Urie type supplied not a Maunsell one.

Anyway the little loco is coming on nicely, good work with the firebox.

Anyway the little loco is coming on nicely, good work with the firebox.

Heather Kay

Western Thunderer

Focalplane

Western Thunderer

Nicely done, Heather! It's always useful having that spare sprue, is it not! Rule 2 - never throw anything away that will fit in the parts box!

Paul

Paul

Heather Kay

Western Thunderer

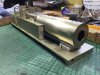

There are several etched corner profiles in the kit, which I assume are intended to give some meat to the rounded corners. I’m pleased with how the firebox turned out. Let’s hope I can make the rest of the boiler look right!

Heather Kay

Western Thunderer

It’s taken a long time to get here - and it’s not even joined together! The boiler barrel has been temporarily tacked to the firebox with low-temp solder. The firebox is currently attached to the cab front with masking tape! I think I can now begin to see how the saddle should fit, and then I can work out how to make a new one.

The reason for the new saddle is inside motion. The valve rods interfere with the cast saddle, and, like the firebox, the casting isn’t quite right to my eye. Time for some serious photo peering, followed by some CAD.

Heather Kay

Western Thunderer

Heather Kay

Western Thunderer

Heather Kay

Western Thunderer

By my usual standards, I think that was a good day at the bench.

An obligatory posed shot with the smokebox saddle definitely in the wrong place! I’ve just realised I might need to think carefully about the rear truck: it’s currently off the chassis as there’s the main body fixing nut right above it. I might need to see if reassembling the truck can be done with the body in situ.

Anyway, can you spot anything else new?

Beading! I’ve used half-round 0.7mm wire, which is a little over scale. I think it looks okay. The bunker front bits also work well, so I’m glad I took a little time to add them. Tomorrow, after domestic stuff in the morning, I propose to tackle some of the details at the front of the cab.

An obligatory posed shot with the smokebox saddle definitely in the wrong place! I’ve just realised I might need to think carefully about the rear truck: it’s currently off the chassis as there’s the main body fixing nut right above it. I might need to see if reassembling the truck can be done with the body in situ.

Anyway, can you spot anything else new?

Beading! I’ve used half-round 0.7mm wire, which is a little over scale. I think it looks okay. The bunker front bits also work well, so I’m glad I took a little time to add them. Tomorrow, after domestic stuff in the morning, I propose to tackle some of the details at the front of the cab.