S-Club-7

Western Thunderer

The first one out of the blocks:

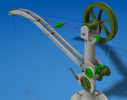

7mm/ft 1:43.5 scale model of GWR-style stop block as seen at Minehead on the West Somerset Railway.

Available now from Off The Rails in the Shapeways FUD acrylic. Unfortunately some parts are too small to be produced reliably in the less expensive WSF nylon material so this option will not be available online; however as the designer I'm allowed to order them under the Shapeways "print regardless" scheme which means they may be available from a well-known S7 retailer at Brightwell-cum-Sotwell in April.

7mm/ft 1:43.5 scale model of GWR-style stop block as seen at Minehead on the West Somerset Railway.

Available now from Off The Rails in the Shapeways FUD acrylic. Unfortunately some parts are too small to be produced reliably in the less expensive WSF nylon material so this option will not be available online; however as the designer I'm allowed to order them under the Shapeways "print regardless" scheme which means they may be available from a well-known S7 retailer at Brightwell-cum-Sotwell in April.

or spacious

or spacious

.

.