richard carr

Western Thunderer

I purchased this TEA wagon at Kettering in March and thought it was time I built something in brass, something I haven't done for a while.

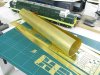

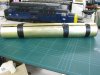

Here it is out of the box

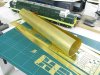

There is one main etched sheet from which Ihave removed one of the chassis ends and some very long etches that make up the brass channel for the chassis and the angle to support the tank.

There is a bag of quite nice castings for the tank ens, the bogies and the brake equipment

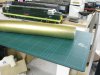

The tank comes as a pre rolled sheet of brass.

Now the interesting bit, there are extensive instructions, you can see them all here in the next photo.

Thats it one page of instructions and on the previous page in very small print a note to tell you to cut the brass channel to a length of 397mm and the angle to 374mm. Not a lot tog go on.

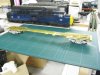

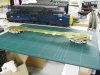

The first part to deal with is the chassis ends, here it is in the flat

It took a good hour to work out how it folds up and thank goodness for Paul Bartletts wagon photos I would have struggled without them.

The first thing is to fold up the top deck above the buffer beam like so.

The next part is to fold the buffer beam up and then back on itself into the half etched recesses in the beam itself.

The buffer beam folder up

Then back on itself you also need to fold the outer edges of the solebar out the way for now.

This is how it looks from above

Here it is out of the box

There is one main etched sheet from which Ihave removed one of the chassis ends and some very long etches that make up the brass channel for the chassis and the angle to support the tank.

There is a bag of quite nice castings for the tank ens, the bogies and the brake equipment

The tank comes as a pre rolled sheet of brass.

Now the interesting bit, there are extensive instructions, you can see them all here in the next photo.

Thats it one page of instructions and on the previous page in very small print a note to tell you to cut the brass channel to a length of 397mm and the angle to 374mm. Not a lot tog go on.

The first part to deal with is the chassis ends, here it is in the flat

It took a good hour to work out how it folds up and thank goodness for Paul Bartletts wagon photos I would have struggled without them.

The first thing is to fold up the top deck above the buffer beam like so.

The next part is to fold the buffer beam up and then back on itself into the half etched recesses in the beam itself.

The buffer beam folder up

Then back on itself you also need to fold the outer edges of the solebar out the way for now.

This is how it looks from above

.

.