Rob Pulham

Western Thunderer

Progress on the bogies hasn't been quick due in part to me not feeling at my best and then due to the instructions on the Kemilway bogies telling you to drill through the shock absorber castings with a 0.6mm drill.

This hasn't proved easy and 6 broken drill bits later, having only got through 4 of the 16 castings I abandoned that idea and took the safer route. This route had me drilling either end of the casting and fitting a stub of 0.6mm nickel rod in the bottom of the castings and then shortening the spring rod and inserting it into the top of the casting before solder them on.

This is a shot with them complete on one of the bogies and very nice they look too - they have a nice chunky feel to them now

.

I haven't made much progress on the Newbould versions beyond soldering up the springs and studying the shock absorber castings which already have a screw thread at the bottom - this is what I believe the 0.6mm rod represents on the Kemilway version.

This hasn't proved easy and 6 broken drill bits later, having only got through 4 of the 16 castings I abandoned that idea and took the safer route. This route had me drilling either end of the casting and fitting a stub of 0.6mm nickel rod in the bottom of the castings and then shortening the spring rod and inserting it into the top of the casting before solder them on.

This is a shot with them complete on one of the bogies and very nice they look too - they have a nice chunky feel to them now

.

I haven't made much progress on the Newbould versions beyond soldering up the springs and studying the shock absorber castings which already have a screw thread at the bottom - this is what I believe the 0.6mm rod represents on the Kemilway version.

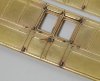

I added a block (from square brass bar) for the wiring loom and an eye to connect a restraining chain. The "wiring" will be cut shorter and soldered to the underframe once I fit it.

I added a block (from square brass bar) for the wiring loom and an eye to connect a restraining chain. The "wiring" will be cut shorter and soldered to the underframe once I fit it.