Rob Pulham

Western Thunderer

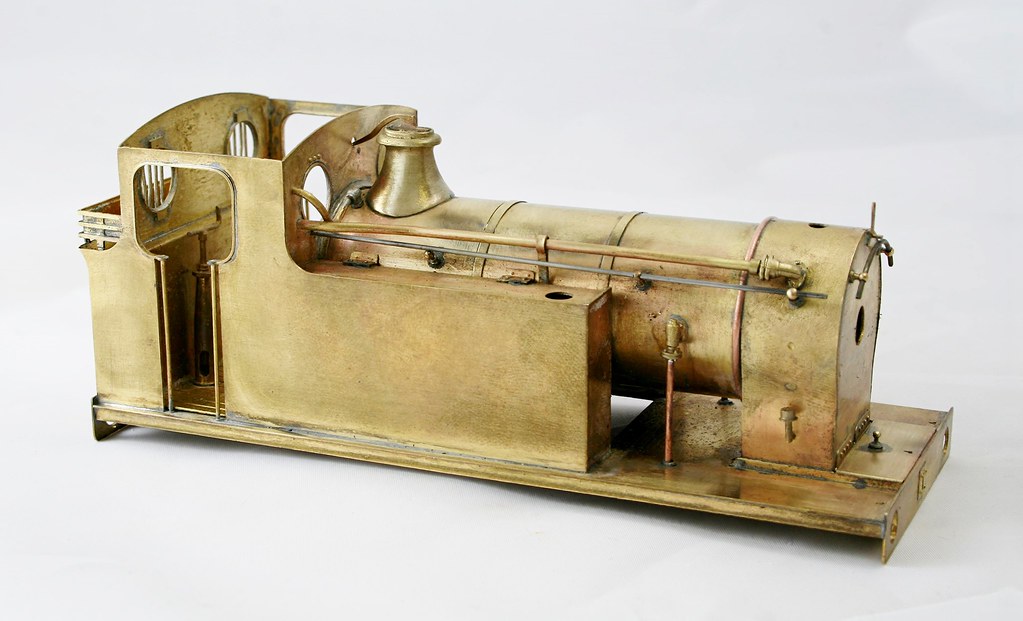

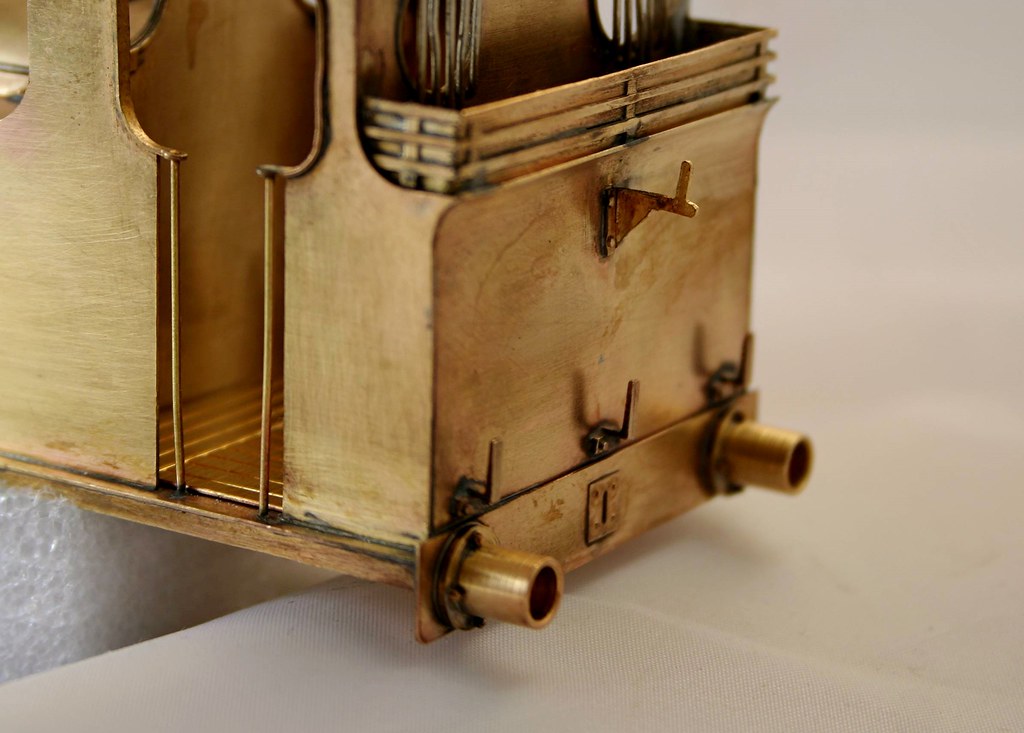

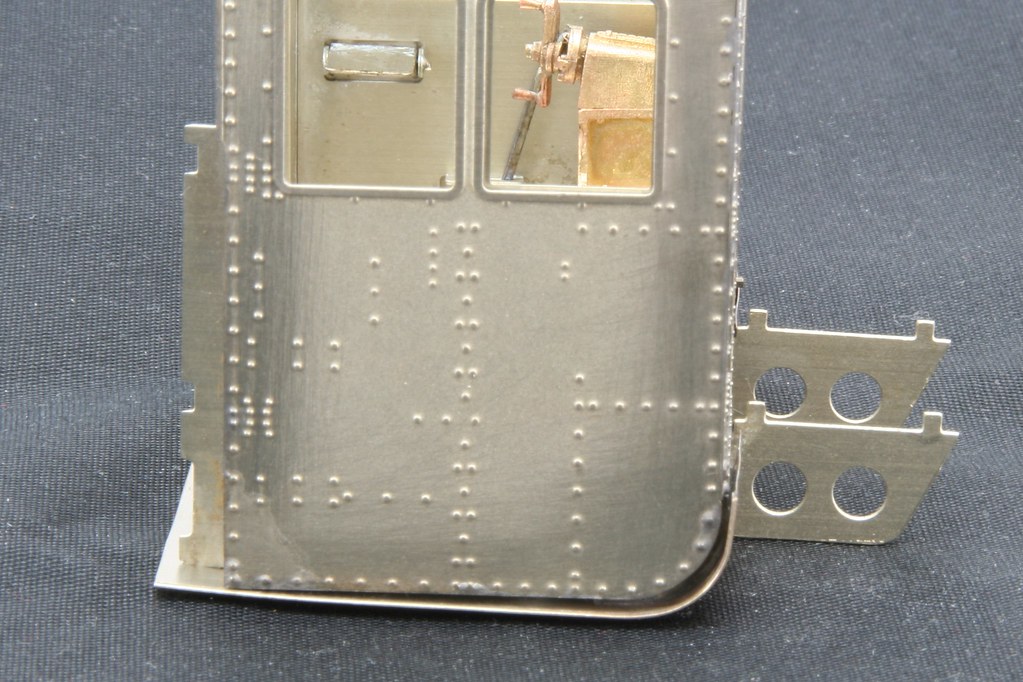

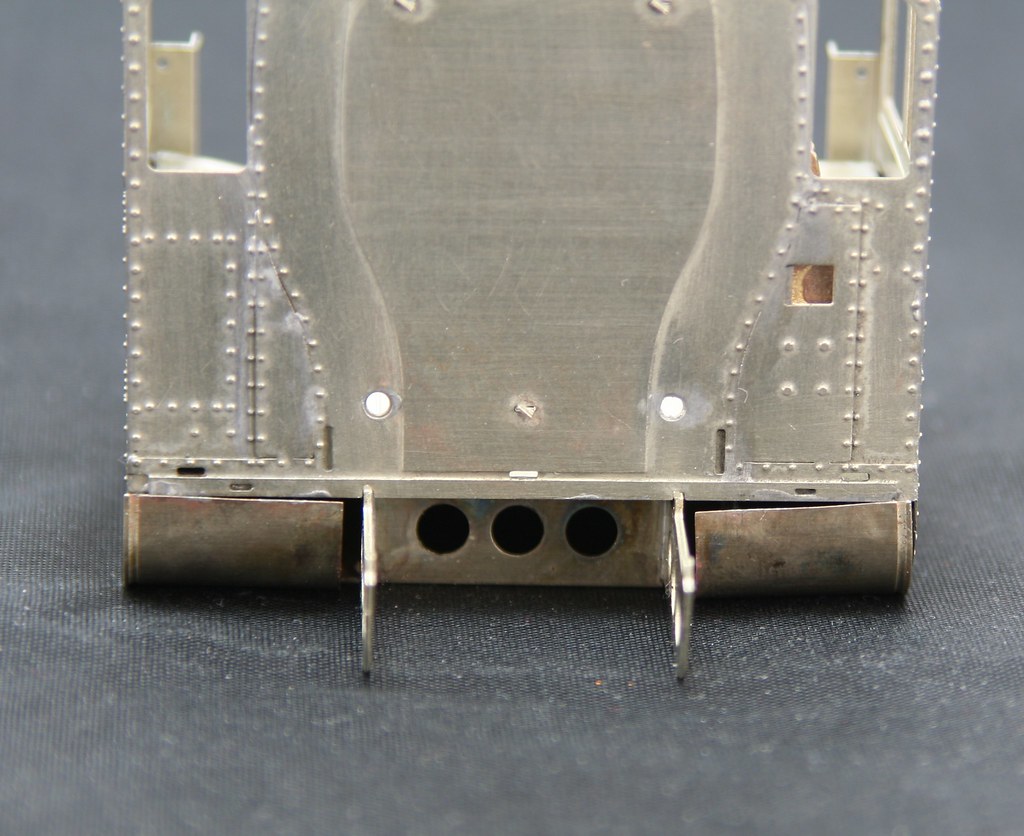

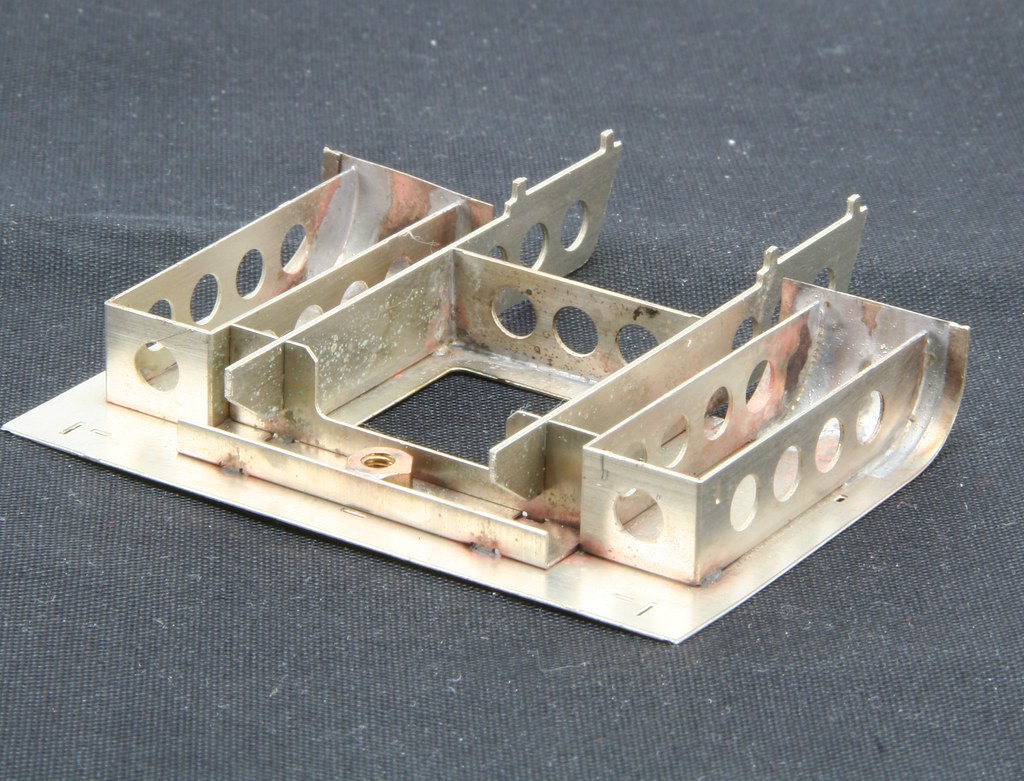

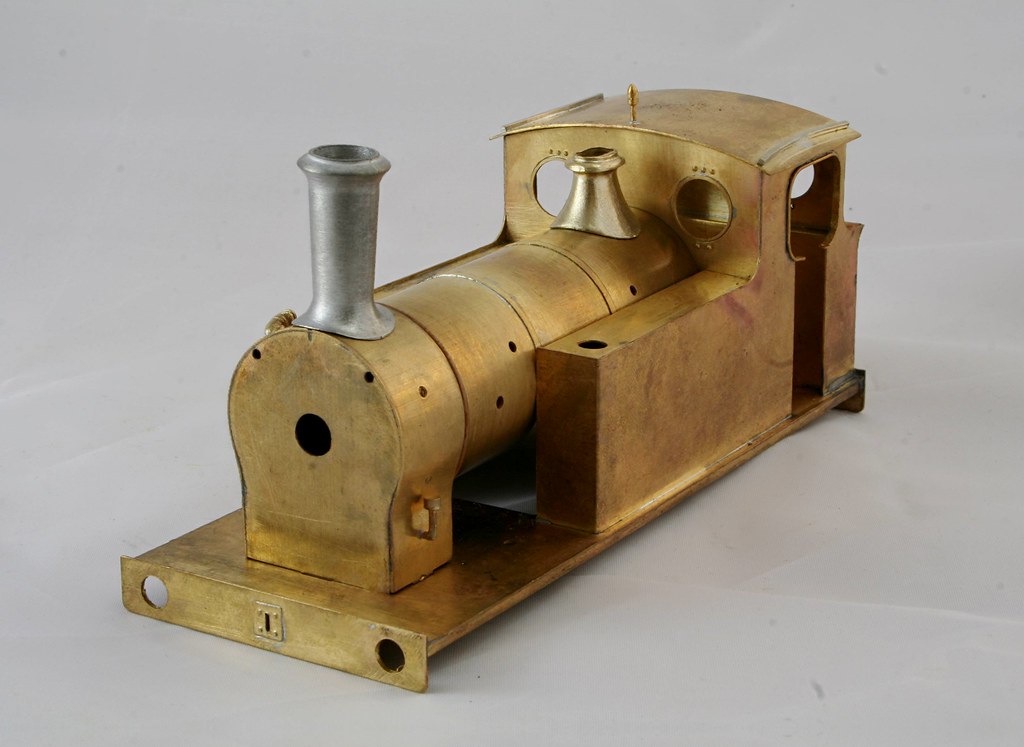

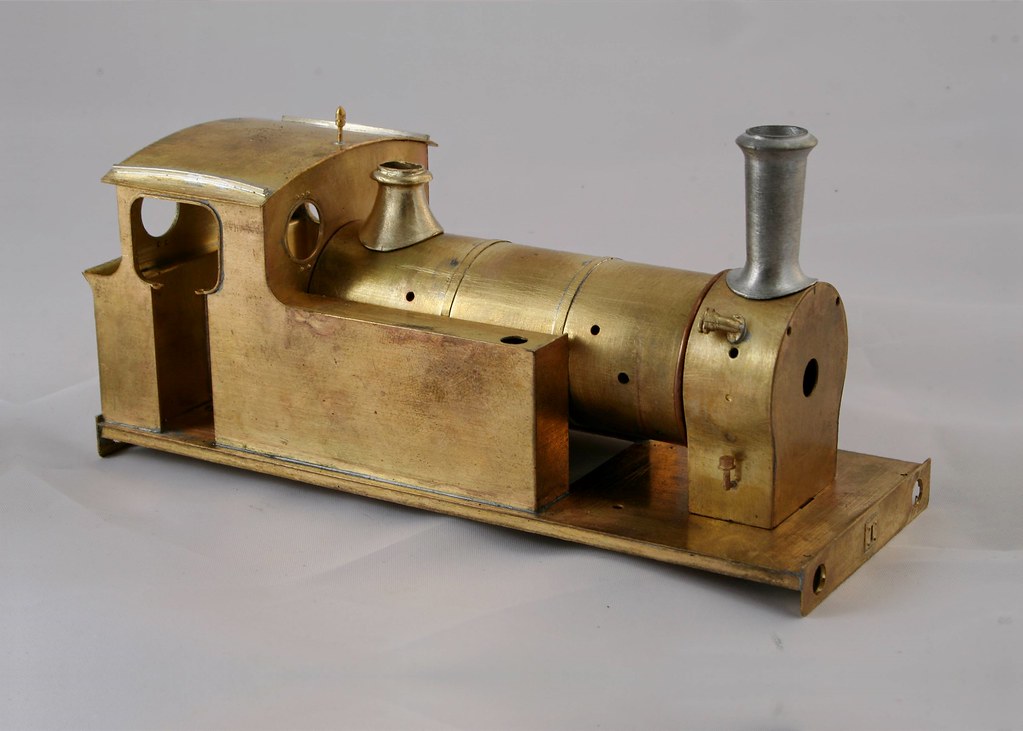

Work has progressed a little this week with me adding the cab beading and fitting the cab/bunker/tank sides to the footplate. I took a bit of care to make sure that I got the sides to the outer edge of the etched slots in the footplate - this is an older kit and some of the slots are slightly over etched.

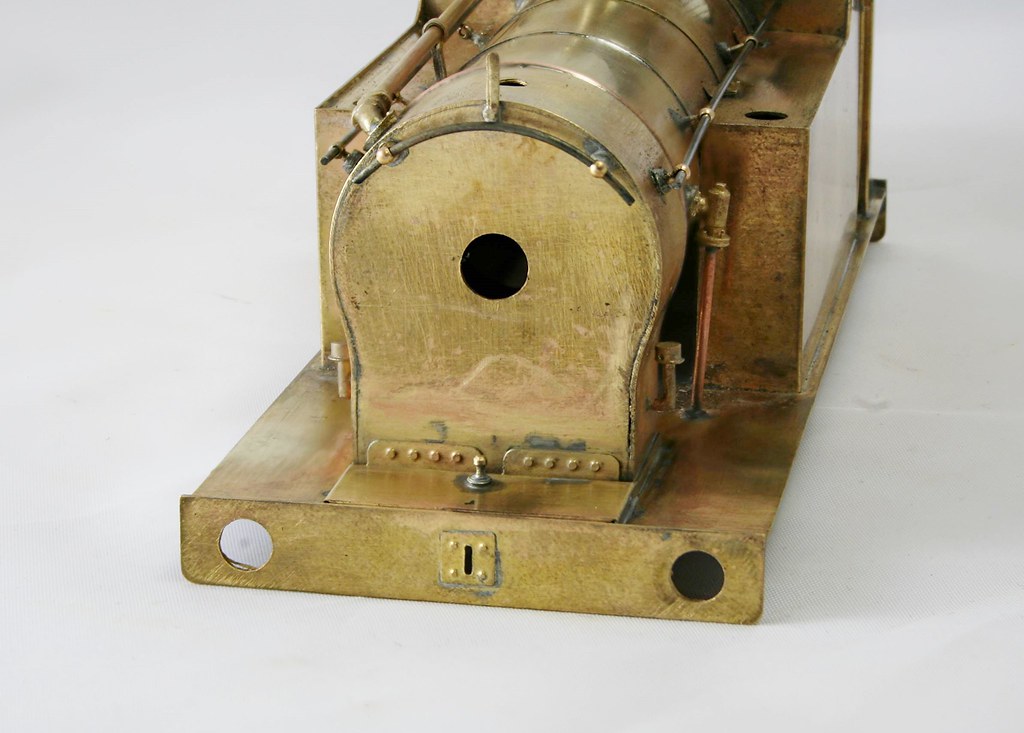

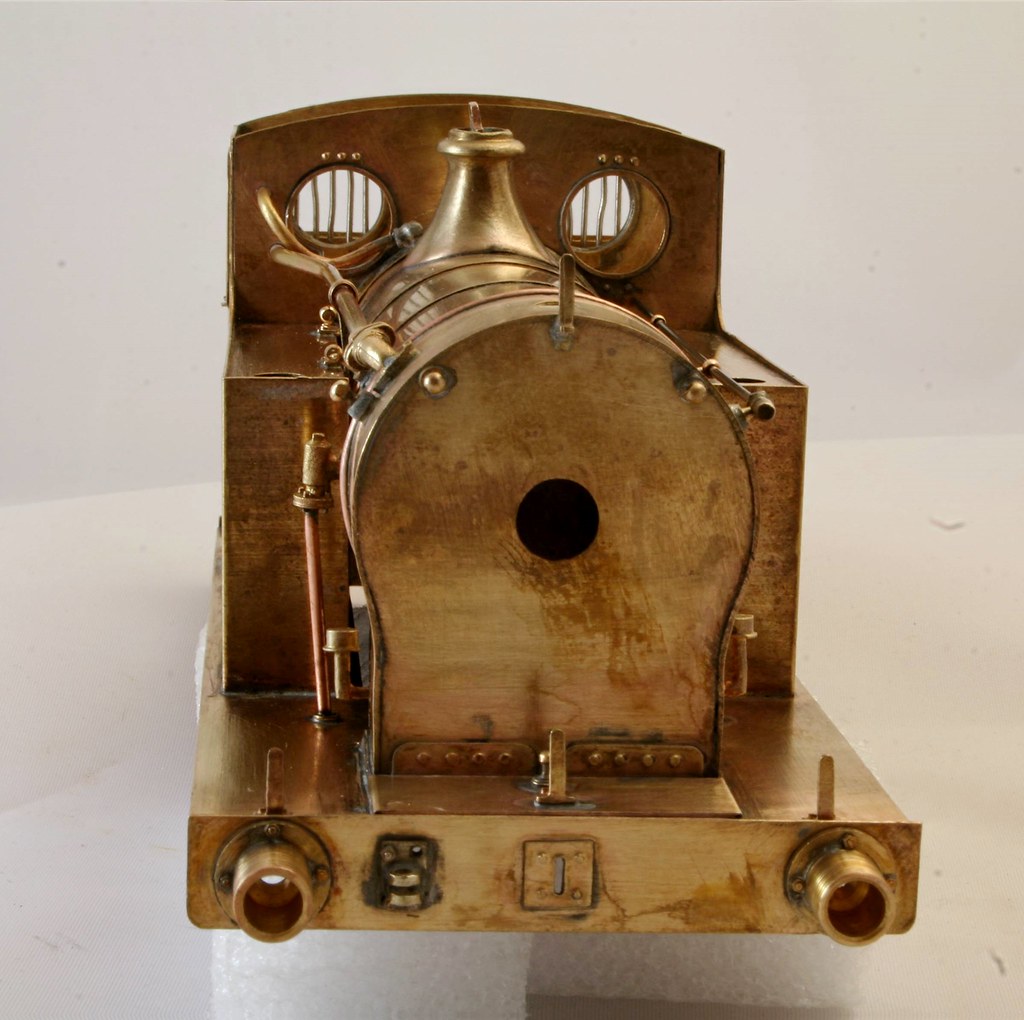

I then looked to fit the bunker rear and found that there is a slight gap at one side so I am probably going to have to adjust the left hand side as you view it from the rear. that may mean that I need to fill a small gap in the footplate top time will tell.

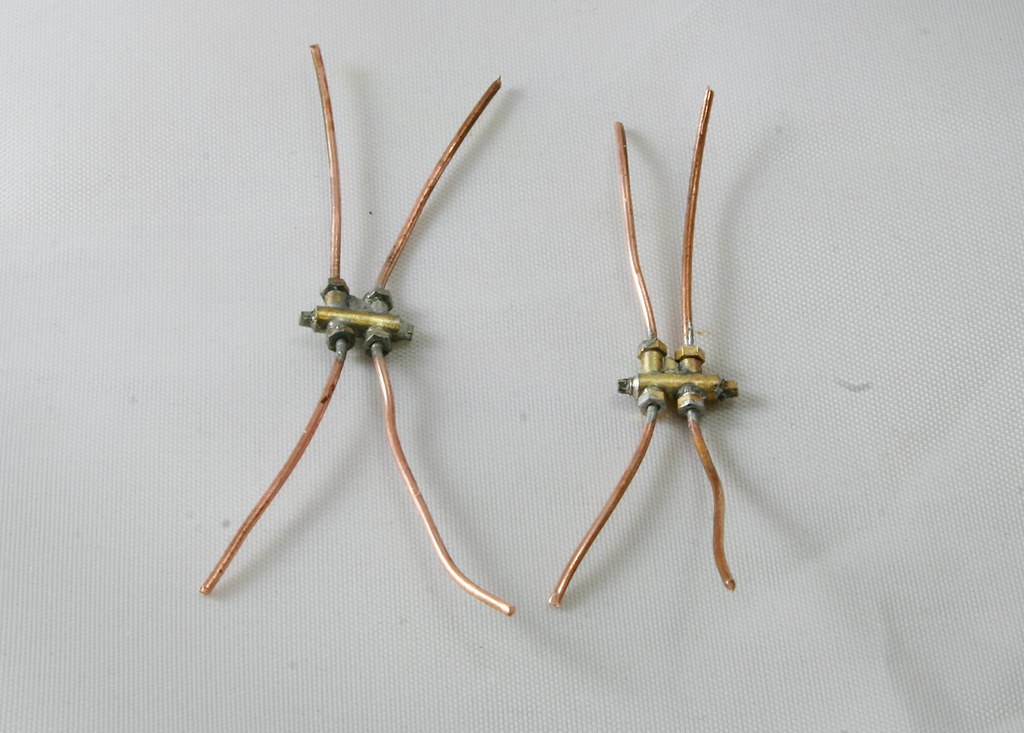

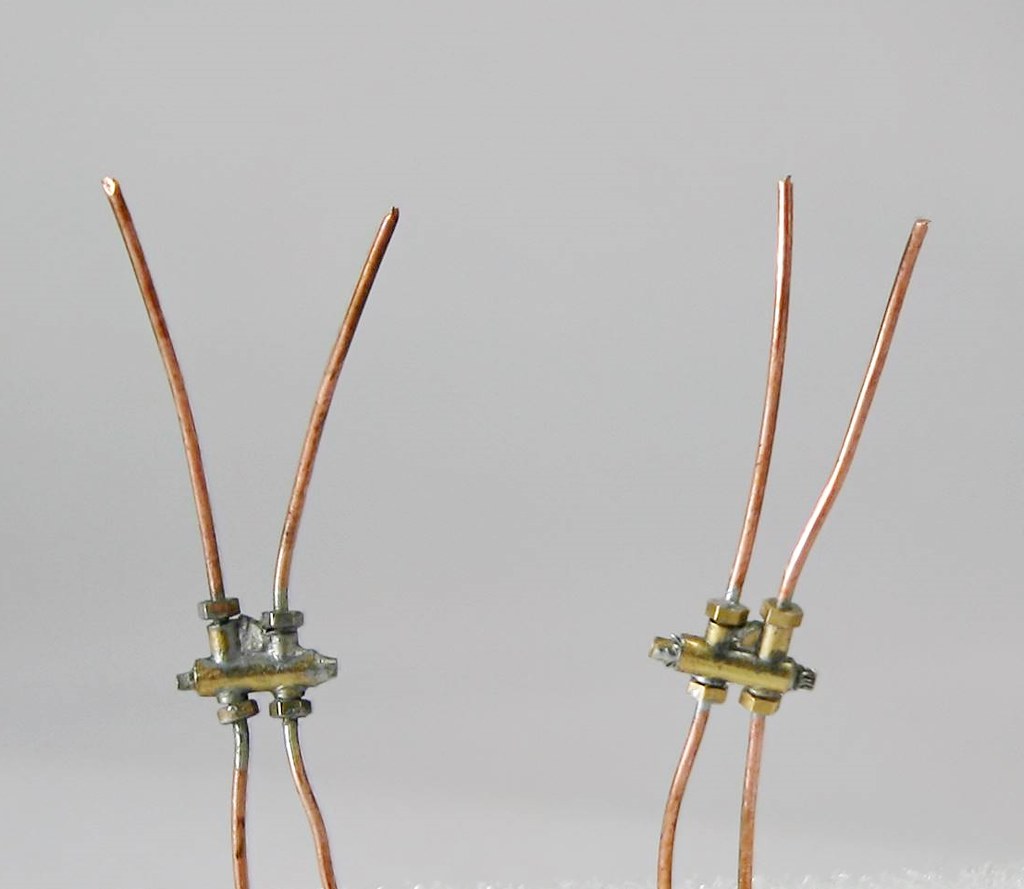

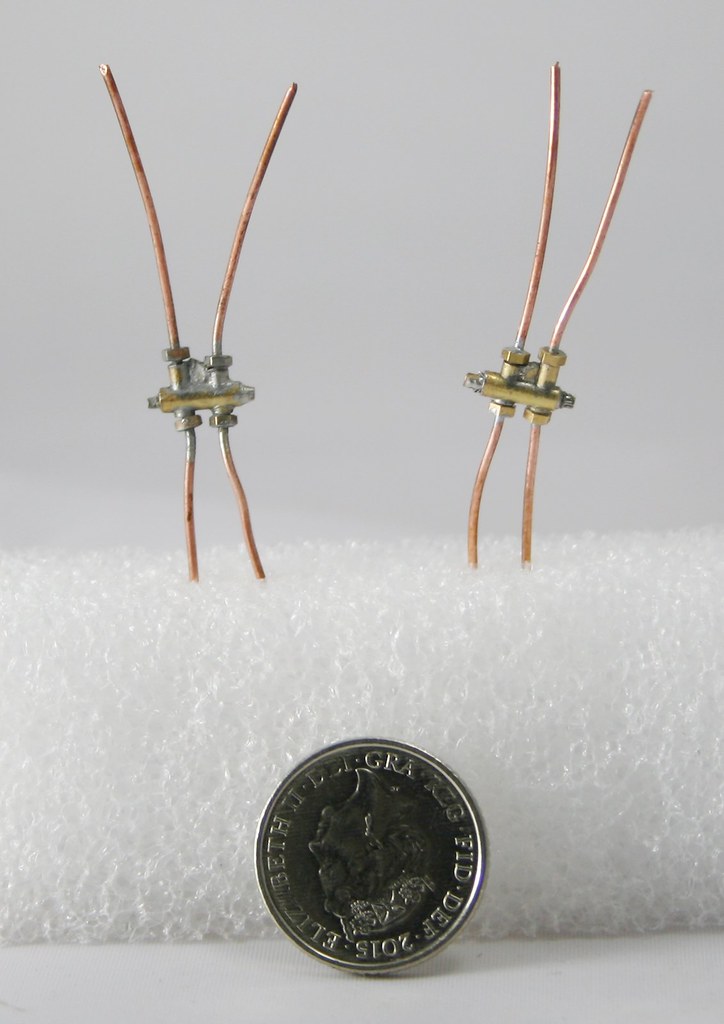

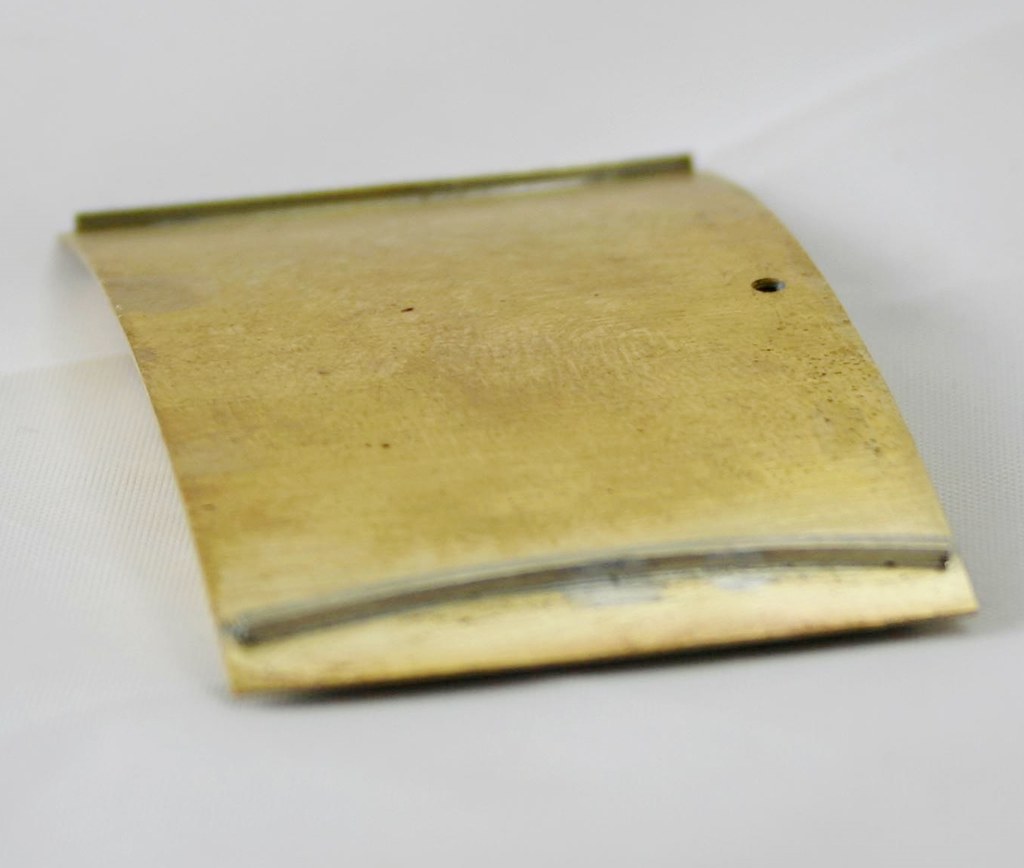

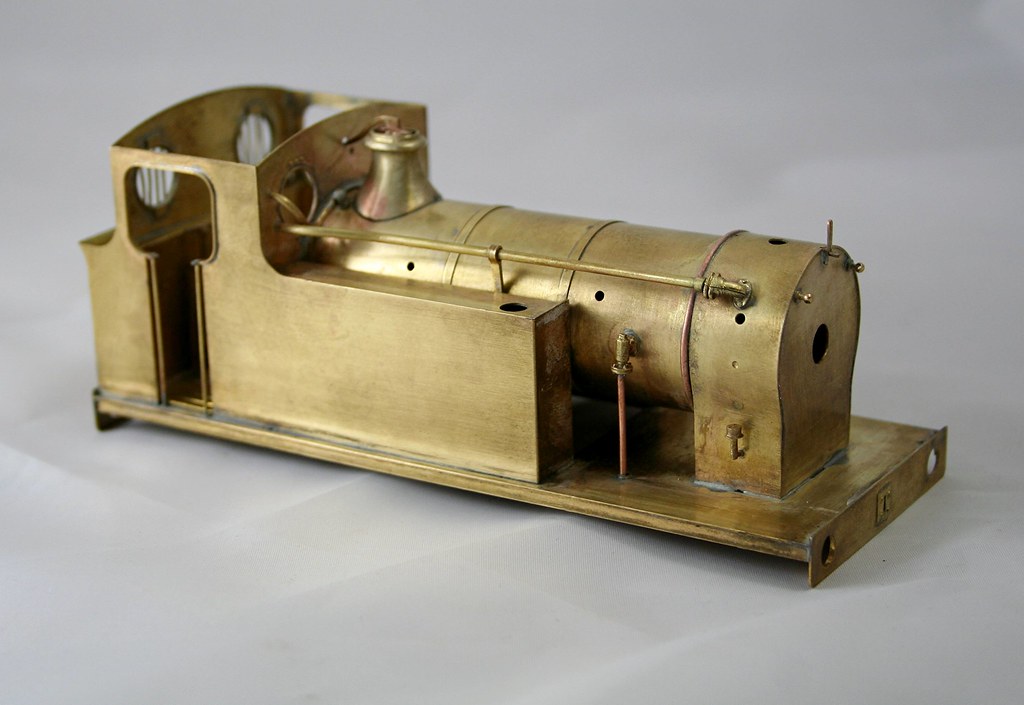

It was getting late by the time I discovered that so I moved onto something a little easier for my last 15 minutes or so. Namely the cab roof. I am quite impressed by Jim's design for this because it's usually a bit of a fiddle to get it to sit square and be retained in the cab. Jim's answer is a nifty fold up etch.

A note to anyone building one of these, there are half etched curves in the roof for locating the rain strips (the idea is that you solder in a length of thin wire and it becomes a half round rain strip). when rolling, the roof has a tendency to fold rather than roll smoothly. Backing it with a bit of card as it goes through the rollers would probably help with this.

Having none to hand I didn't bother, I just stopped passing it through the rollers right to the ends of the roof and effectively just rolled the middle section. I also replaced the wire with some small square section rod that I had in stock.

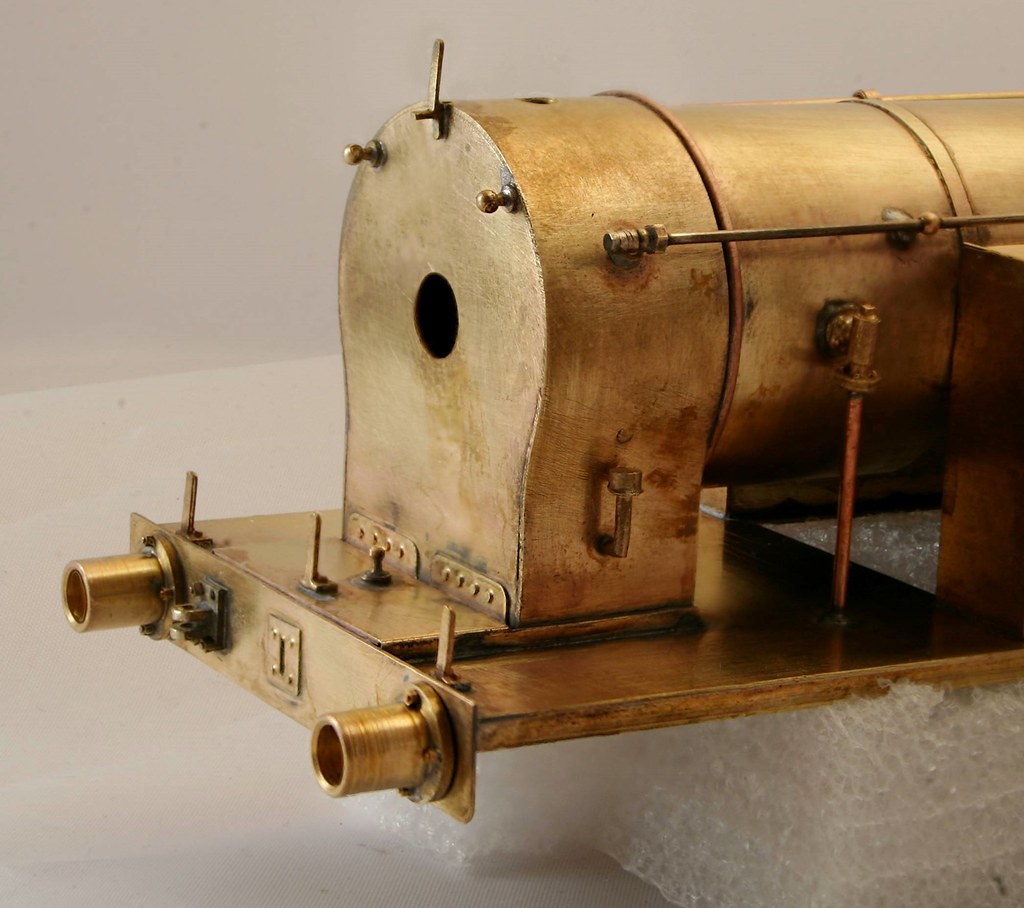

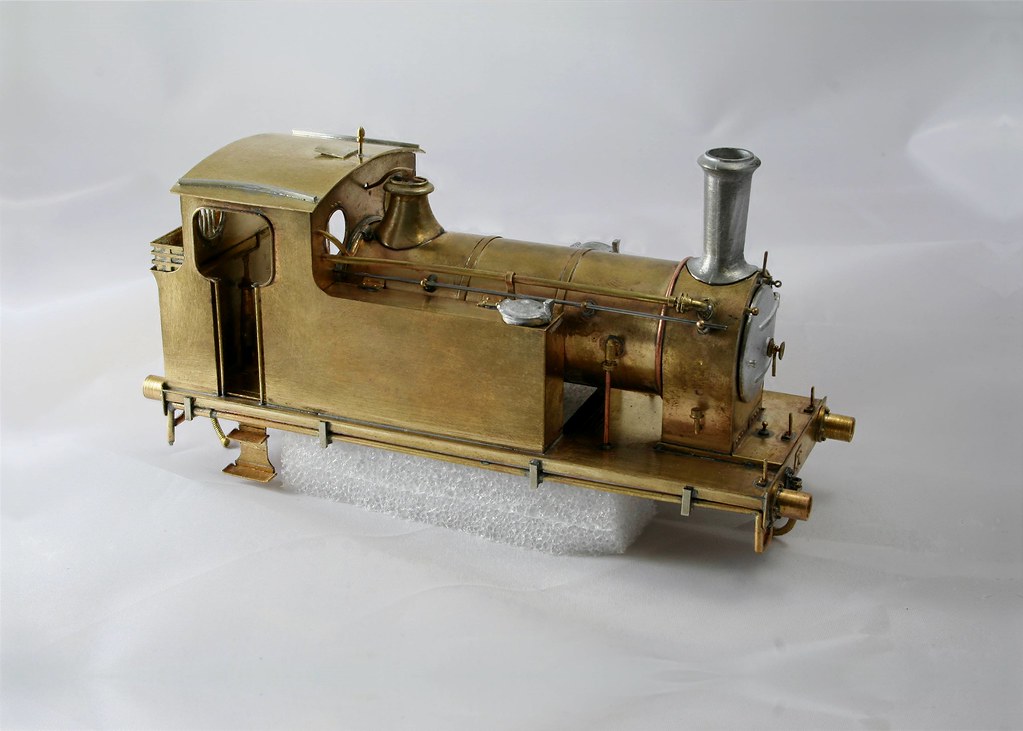

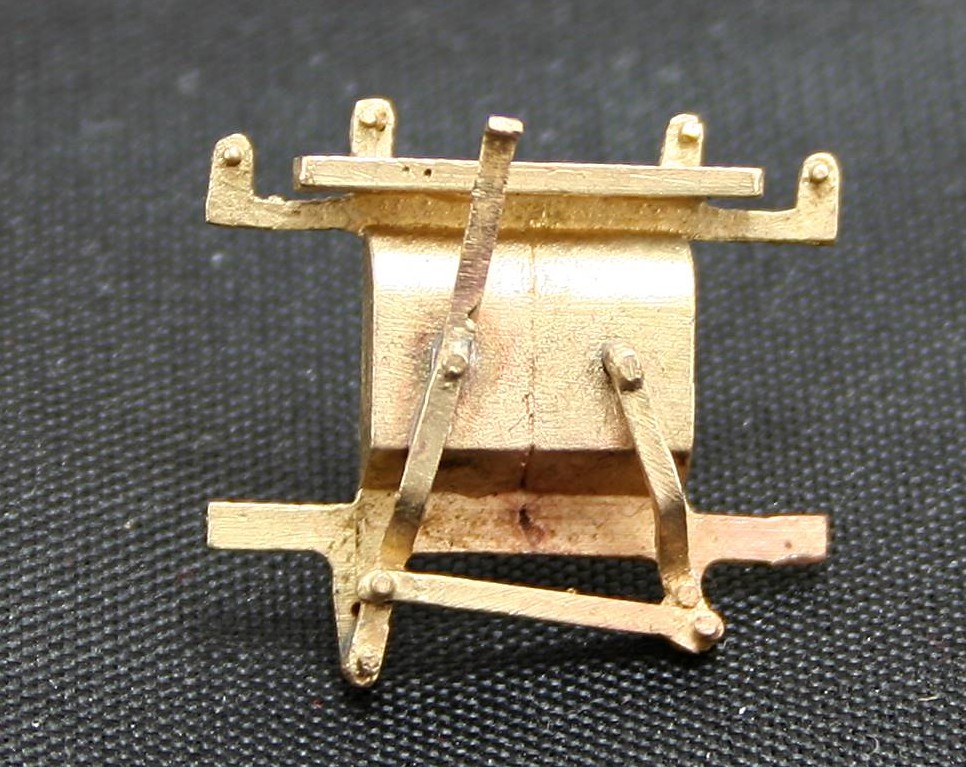

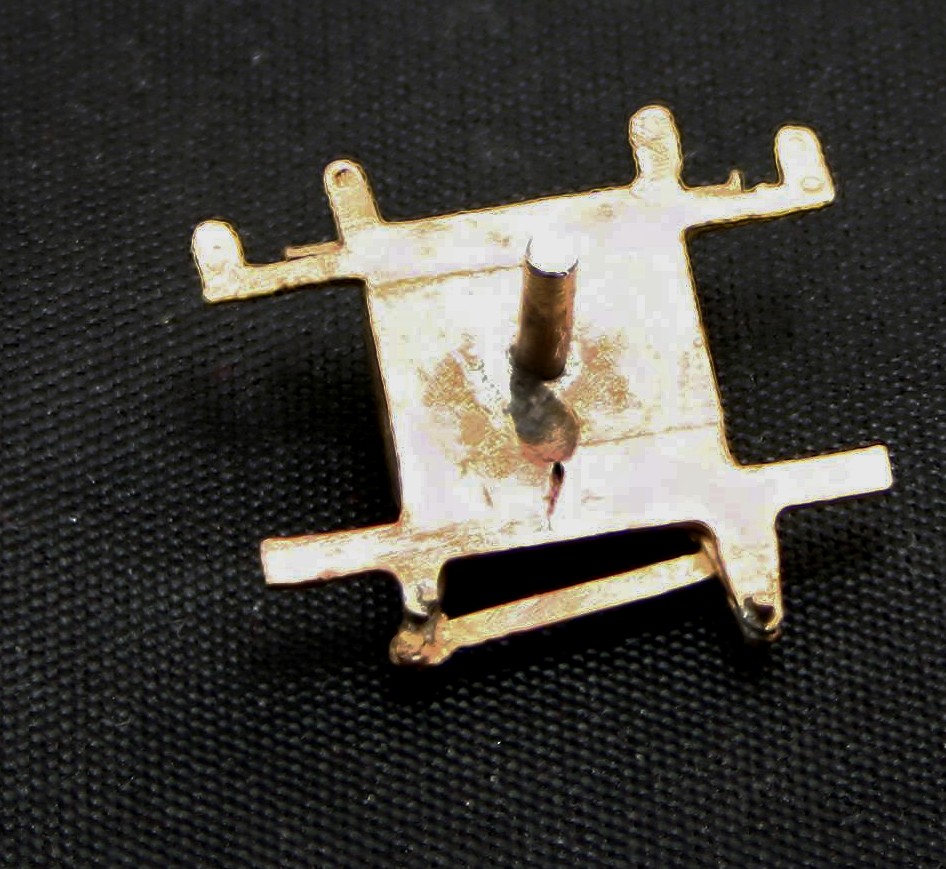

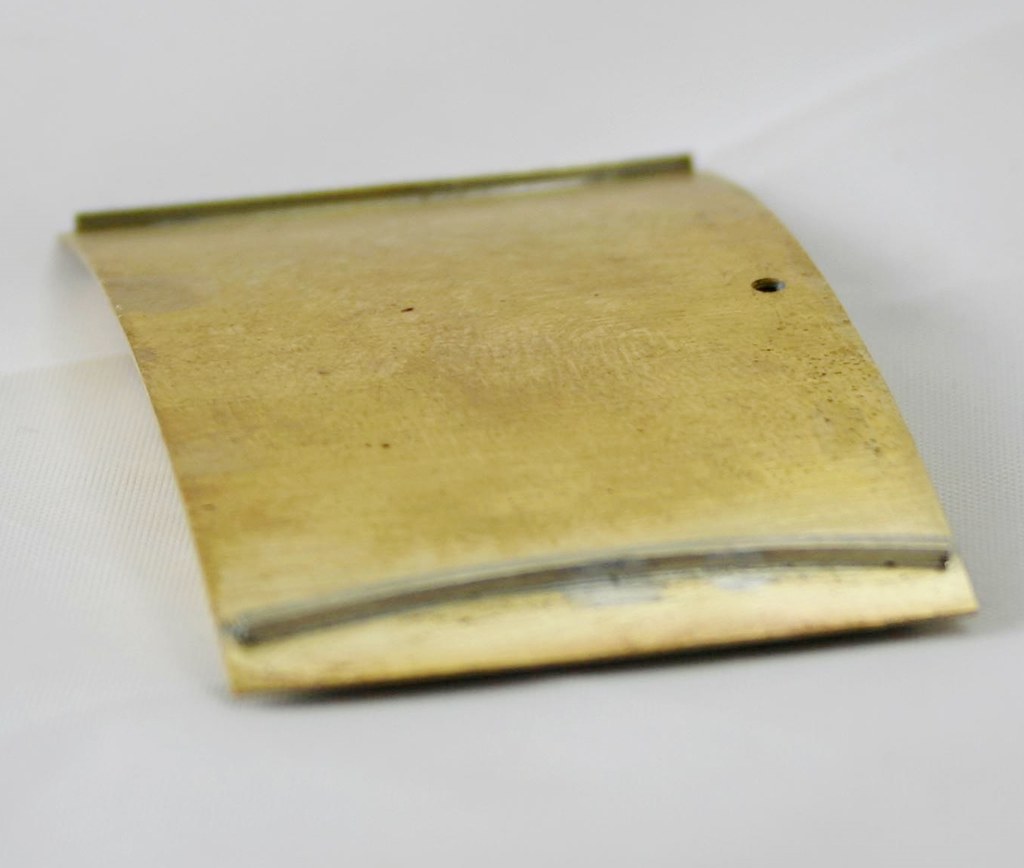

Lastly in true Blue Peter fashion, here's a bit that I did earlier. I had previously added the spacers and the boiler bands to the boiler but had popped it back in the kit box so missed taking any photos of it when I took the photos that I shared the other day.

I then looked to fit the bunker rear and found that there is a slight gap at one side so I am probably going to have to adjust the left hand side as you view it from the rear. that may mean that I need to fill a small gap in the footplate top time will tell.

It was getting late by the time I discovered that so I moved onto something a little easier for my last 15 minutes or so. Namely the cab roof. I am quite impressed by Jim's design for this because it's usually a bit of a fiddle to get it to sit square and be retained in the cab. Jim's answer is a nifty fold up etch.

A note to anyone building one of these, there are half etched curves in the roof for locating the rain strips (the idea is that you solder in a length of thin wire and it becomes a half round rain strip). when rolling, the roof has a tendency to fold rather than roll smoothly. Backing it with a bit of card as it goes through the rollers would probably help with this.

Having none to hand I didn't bother, I just stopped passing it through the rollers right to the ends of the roof and effectively just rolled the middle section. I also replaced the wire with some small square section rod that I had in stock.

Lastly in true Blue Peter fashion, here's a bit that I did earlier. I had previously added the spacers and the boiler bands to the boiler but had popped it back in the kit box so missed taking any photos of it when I took the photos that I shared the other day.

.

.