You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

dibateg

Western Thunderer

Thank you chaps.

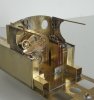

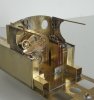

Inside motion for the coal tank:-

The crank axle has been prepared. The cranks are drilled and pinned with 0.8mm n/s wire. Crossheads and slidebars fettled. The Connecting rods are drilled and the lower part of the end piece is tapped 14BA. They will be quite short once all the dimensions have been worked out. The screws are not prototypical, but won't be seen inside the recesses of the engine. It means this part of the motion can be taken down and the crank axle dropped out.

I use plumbers flux and solder paste on the crank axle and it is heated up with the blow torch until the solder flows. I added some flux cored 60/40 whilst it was still hot to fill in any gaps. Any excess can be removed later. I should have photo'd the blackened item after it was done, but here it is cleaned up and the axle cut out to form the cranks. I can see some bits need a final tidy. In the LNWR motion kit the eccentric straps come in two parts - that's a lot easier than the one piece ones that have to endure the blowtorch and not be soldered to the eccentrics - they are blackened in that instance to prevent that.

Next thing is to get them all roughly assembled, make sure they will work, then a good clean up before final assembly.

Inside motion for the coal tank:-

The crank axle has been prepared. The cranks are drilled and pinned with 0.8mm n/s wire. Crossheads and slidebars fettled. The Connecting rods are drilled and the lower part of the end piece is tapped 14BA. They will be quite short once all the dimensions have been worked out. The screws are not prototypical, but won't be seen inside the recesses of the engine. It means this part of the motion can be taken down and the crank axle dropped out.

I use plumbers flux and solder paste on the crank axle and it is heated up with the blow torch until the solder flows. I added some flux cored 60/40 whilst it was still hot to fill in any gaps. Any excess can be removed later. I should have photo'd the blackened item after it was done, but here it is cleaned up and the axle cut out to form the cranks. I can see some bits need a final tidy. In the LNWR motion kit the eccentric straps come in two parts - that's a lot easier than the one piece ones that have to endure the blowtorch and not be soldered to the eccentrics - they are blackened in that instance to prevent that.

Next thing is to get them all roughly assembled, make sure they will work, then a good clean up before final assembly.

dibateg

Western Thunderer

So, with reference to the GA, I'm here checking the fit of the critical motion parts. Parts are wedged into place and a 6BA screw allows me to rotate the axle and check for clearances and binding. The slidebars were then tacked in place ( they are very close to the leading axle ) and then parts are added one at a time. Each time checking it all moves freely. Most of my own inside cylinder locos have inside motion, it gives me a good deal of satisfaction. Twenty years ago, I wouldn't dreamed that I was capable of doing this sort of thing, that was the territory of well know craftsmen in our hobby, but I owe it to Lambert and Wright, and others that helped and inspired me.

Next, I shall make the motion bracket that support the end of the slidebars, and have a 'play' with the valve gear....

Next, I shall make the motion bracket that support the end of the slidebars, and have a 'play' with the valve gear....

john lewsey

Western Thunderer

LNWR brilliant

dibateg

Western Thunderer

That 'play' with the valve gear took a little while as the radius rods are quite short on this loco. It all fits in and works. There is some tidying up to do, getting it working freely was the main objective. The con rods and cross heads can be dropped out by releasing the big end cap and the motion is disconnected from the by withdrawing a 14BA screw from the weighshaft arms. Then the whole crank axle and attached spaghetti can be dropped out.

Talking of the weighshaft, the ones in the motion kit are not like coal tanks ones. So I had to fabricate these, they are of cranked appearance with smaller weights - utilising 6BA screw heads for the balance weights.

Coupling rod 'fun' next...

Talking of the weighshaft, the ones in the motion kit are not like coal tanks ones. So I had to fabricate these, they are of cranked appearance with smaller weights - utilising 6BA screw heads for the balance weights.

Coupling rod 'fun' next...

dibateg

Western Thunderer

Period engines often feature pairs of brake pull rods either side of the wheels. With our models, these pose a potential shorting risk, especially as there needs to be some movement laterally in the axles to allow the loco to negotiate six foot radius curves. I was pondering this and whilst away for a couple of days had a brainwave in the middle of the night - I could use some fine ptfe tube that I have to insulate the brake gear on it's hangers. Before that though, I had the next issue to resolve - there are only two pull rods in the kit. So the only way was to remove them from the fret and solder them to some drawn hard brass strip. The holes could then be drilled and the rods filed to shape. Tedious and fingerprint removing.. The brake gear has to be removable, so is held on with nuts to the 12BA studs. There is no representation of the brake lever in the kit, |I made that up from some redundant 9F combination levers! There are also plastic inserts in the radial truck cut out to prevent shorts. The ptfe tube is almost invisible behind the brake hanger nuts.

One feature of LMS days is that they put bars over the rear cab windows. Again - no provision in the kit, so I made up a jig to mark them out. Checking with my old school ruler, they are not at 60 or 72 degrees - something in between! Access is required to the bunker space, so I have to come up with a solution that fits around the toolboxes, beading and water filler. I think now, this is the worst kit I have ever had to put together.

One feature of LMS days is that they put bars over the rear cab windows. Again - no provision in the kit, so I made up a jig to mark them out. Checking with my old school ruler, they are not at 60 or 72 degrees - something in between! Access is required to the bunker space, so I have to come up with a solution that fits around the toolboxes, beading and water filler. I think now, this is the worst kit I have ever had to put together.

Last edited:

Heather Kay

Western Thunderer

I think now, this is the worst kit I have ever had to put together.

I am sure, though, that from a sow's ear will emerge a beautiful silk purse.

dibateg

Western Thunderer

Thanks Heather -

The interior of the rear bulkhead is now a little more populated. The instructions do suggest scratching up the tool box doors from scrap etch.

David Hill kindly supplied me with some toolboxes, they are longer than those supplied in the kit. They butt up against the rear of the cab. Lamp irons have been added, the LMS replaced the LNWR sockets with irons. There is some tidying up to do, once the loco is assembled. Most of the castings are brass, from Laurie's range and they are of good quality.

The 'floor' of the coal space is removable to allow access to the inside of the bunker. The tool boxes are not fixed yet, I always leave white metal to the last.

I managed to plonk everything together to get it to look like a loco at last. The flairs have yet to be cut off the smokebox. Only the main tanks and cab front are fixed.

It's a busy little cab, and I wanted to get as much in as possible before putting the bunker on. Most of the rest like the manifold, will be mounted on the back head. I needed to create the two substantial oval plates on the tank tops. BR Standards to the rescue again, I had an oval plate spare from the MOK class for tank, so I soldered it to some scrap etch and filed another to shape. The cast fitting is a cut down MOK sand pipe union! When built, the tanks were balance by a box section across the cab door way. This must have rusted like hell, so it seems that later on the box was replaced by a pipe with a shaped cover over it, so that there was room for the crews boots to fit on the step. So I shaped those up from some spare sheet. Just the sight feed lubricator to sort out...

The interior of the rear bulkhead is now a little more populated. The instructions do suggest scratching up the tool box doors from scrap etch.

David Hill kindly supplied me with some toolboxes, they are longer than those supplied in the kit. They butt up against the rear of the cab. Lamp irons have been added, the LMS replaced the LNWR sockets with irons. There is some tidying up to do, once the loco is assembled. Most of the castings are brass, from Laurie's range and they are of good quality.

The 'floor' of the coal space is removable to allow access to the inside of the bunker. The tool boxes are not fixed yet, I always leave white metal to the last.

I managed to plonk everything together to get it to look like a loco at last. The flairs have yet to be cut off the smokebox. Only the main tanks and cab front are fixed.

It's a busy little cab, and I wanted to get as much in as possible before putting the bunker on. Most of the rest like the manifold, will be mounted on the back head. I needed to create the two substantial oval plates on the tank tops. BR Standards to the rescue again, I had an oval plate spare from the MOK class for tank, so I soldered it to some scrap etch and filed another to shape. The cast fitting is a cut down MOK sand pipe union! When built, the tanks were balance by a box section across the cab door way. This must have rusted like hell, so it seems that later on the box was replaced by a pipe with a shaped cover over it, so that there was room for the crews boots to fit on the step. So I shaped those up from some spare sheet. Just the sight feed lubricator to sort out...

dibateg

Western Thunderer

The saga continues, but I got to a stage where I could plonk things together and we get something that looks like an engine at last. Nothing fits first time, but that's the nature of it. Everything has to be measured for position, I couldn't do it without the GA. The smokebox door is a nice pressing, the safety valve casting has been modified to have Ross pop safety valves. I also added the washout plugs, they don't show on early photos. I've also cut out the coal hole and added some hinges to that door. It's a scratch build really.

The manifold in the kit is not quite right for a Coal Tank, so it has been modified with more scraps of castings and tube to build it up. The whistle sticks out through the cab roof. It's wet from just being washed.

I'm half a day ahead of this now so the removable roof is fitted as is the boiler.

The manifold in the kit is not quite right for a Coal Tank, so it has been modified with more scraps of castings and tube to build it up. The whistle sticks out through the cab roof. It's wet from just being washed.

I'm half a day ahead of this now so the removable roof is fitted as is the boiler.

dibateg

Western Thunderer

Nearly there - the sanding mechanism either side of the smokebox was a right battle. Both castings seems to be for the left hand side. So the right hand one had to be cut up with the piercing saw into it's component parts - it's longer and the cranks are separate ( 9F parts to the rescue again! ). A job that should take 15 mins took an hour... I've reworked the brakes and re-sited the hangers, they look a lot better. The steps actually fitted without any modification! Roof, chimney and dome not yet fixed... Next... lets get it working....

Heather Kay

Western Thunderer

I do like a Coal Tank. Best Beloved built one many years ago, and it pottered around a couple of our exhibition layouts for many a year. We still have. Like a couple of other locos we have, I’m tempted to give them a bit of a makeover when I have some time.

dibateg

Western Thunderer

And here it is. I also scratched up the outriggers on the frames, it looked empty without them. The reworked insulated brake gear is now fitted. Just a few jobs left, fixing the boiler mountings, balance weights, wood ends to the buffer beams, tidying and any other odd details I've missed....

The pick ups and motor are in place , she'll be ready for a track test, maybe next week. It will have proper crankpin nuts on the final assembly.

The pick ups and motor are in place , she'll be ready for a track test, maybe next week. It will have proper crankpin nuts on the final assembly.

dibateg

Western Thunderer

After a little break, I'm back to it ( apart from being recruited for gardening duties by the boss ) and I'm pressing on with the BLP brake gear. With care it goes together nicely to create this small piece of art. I drilled out and pinned the brake blocks as pressing out the half etch dimples were not substantial enough to represent the pins.