P A D

Western Thunderer

Here are the completed connecting rods after addition of the brass cover (at least it will be brass after painting) made from 10 thou plasticard.

Apologies for the plastic dust in many of the photos. I brush it off but static attracts it all back again. I need to give it a wash in water with a little detergent, but that will be done before priming. Moving on to the coupling rods, the bolt heads have been removed from 3 of the crank pin fasteners, which have then been recessed and a nut and bolt added. The fastenings are similar to the ones on LMS/BR locos as fitted to the leading driving wheels. However, they also have an additional locking nut adjacent to the fluting. The joints in the coupling rods are poorly represented but I'm leaving them alone, other than filing down the fixing nut, drilling through and adding a length of brass ros to represent the bolt.

At the back of the chassis, further etched overlays have been added to the frame above the long foot step.

Along with some brackets and bolt head detail lower down.

I ordered a rattle can of RAL 3000 acrylic paint and gave it a quick try yesterday on one of the wheels. Today I brush painted the rim with Humbrol Metalcote steel and after it was dry, polished it up. For doing the painting propper, I intend to decant the Red and apply via an airbrush. Fortunately I have a spare at home as well as a small compressor and with the warmer weather, can spray outside.

At the front of the chassis, I added the piping to the oil boxes either side of the frames, after first making and fitting a plate to cover the opening in the platform in front of the smokebox saddle.

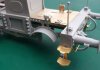

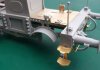

And a view from the front showing the grab rods either side of the buffer beam and the oilpot for lubricating the coupling hook.

Cheers,

Peter

Apologies for the plastic dust in many of the photos. I brush it off but static attracts it all back again. I need to give it a wash in water with a little detergent, but that will be done before priming. Moving on to the coupling rods, the bolt heads have been removed from 3 of the crank pin fasteners, which have then been recessed and a nut and bolt added. The fastenings are similar to the ones on LMS/BR locos as fitted to the leading driving wheels. However, they also have an additional locking nut adjacent to the fluting. The joints in the coupling rods are poorly represented but I'm leaving them alone, other than filing down the fixing nut, drilling through and adding a length of brass ros to represent the bolt.

At the back of the chassis, further etched overlays have been added to the frame above the long foot step.

Along with some brackets and bolt head detail lower down.

I ordered a rattle can of RAL 3000 acrylic paint and gave it a quick try yesterday on one of the wheels. Today I brush painted the rim with Humbrol Metalcote steel and after it was dry, polished it up. For doing the painting propper, I intend to decant the Red and apply via an airbrush. Fortunately I have a spare at home as well as a small compressor and with the warmer weather, can spray outside.

At the front of the chassis, I added the piping to the oil boxes either side of the frames, after first making and fitting a plate to cover the opening in the platform in front of the smokebox saddle.

And a view from the front showing the grab rods either side of the buffer beam and the oilpot for lubricating the coupling hook.

Cheers,

Peter

loads of photos of BR52, 528116.

loads of photos of BR52, 528116.