Max, That's a possibility, even sticking it in the dishwasher might work. My only concern with the dishwasher and very hot water is the temperature shock that the adhesive for those white metal items that I've used it on will go through, only one way to find out I suppose. I'll rest the model on some thin gauze so if anything drops off it won't (hopefully) go down the drain.

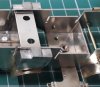

I gave it another wash this evening, very dilute fairy in boiled dehumidifier water. The lack of white stains afterward were pleasing, and those that did occur are buffed out with a soft burnishing brush. However those brown bits just got even browner and some that had been lightly cleaned turn brown again, more blotchy though.

To show how bad it is, here's a clip of the front section of the chassis, I need a close up of the motion bracket and slide bar bracket to show where all the parts go, from above preferably; obviously this will not do.

What I've had to do is crop it to get rid of the worst.

It doesn't really give a balanced visual image but it'll have to do.

If I do primer the chassis in grey then I can take the top shot again and simply replace it as Fig 28 and adjust the tags to suit, for now I have a placed holder in the instructions and can write the text accordingly, thus not slowing down that aspect of the build.

I've a couple more parts to add and that'll complete page five of the chassis build, the rear steps and cylinder cover/front valance will be fitted at or near the very end, experience has shown these two items to be particularly vulnerable during the previous builds.

MD