You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

W1 as rebuilt

- Thread starter Dikitriki

- Start date

-

- Tags

- 7mm djh finney7 kit design lner martin finney

Steph Dale

Western Thunderer

Hehe yes!Nice of Gresley to think ahead ehh

Sadly your comment gave me the best laugh I've had all day. Quite literally, I should get out more.

Sadly your comment gave me the best laugh I've had all day. Quite literally, I should get out more.

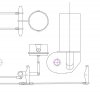

And yep, that's an Mkits 40/15 (40:1 with 15mm mounting centres), for Canon 1833

Steph

P A D

Western Thunderer

Hi Mick,

Very impressive. I really ought to add the double line of rivets either side at the front of the casing to the A4, but any misaligned rivets would look awful in such a prominent position, so I'm still pondering.

I note that the middle sandboxes have the flange and bolt detail, so if the sand valve also has the flange you will need to remove from one or the other, or the valve won't sit down properly.

In what order will you add the running plate and overlay to the resin casing? On the A4, the instruction suggested screwing and gluing the base etch and then soldering the upper overlay aftwards. However, that way you can only solder on the outside edge. I only screwed the base etch, added the overlay and soldered on the outside. Then I unscrewed it and soldered the inner edges, cleaned up then screwed and glued to the resin casing. It's maybe a bit belt and braces soldering both edges but that was my preference.

Cheers,

Peter

Very impressive. I really ought to add the double line of rivets either side at the front of the casing to the A4, but any misaligned rivets would look awful in such a prominent position, so I'm still pondering.

I note that the middle sandboxes have the flange and bolt detail, so if the sand valve also has the flange you will need to remove from one or the other, or the valve won't sit down properly.

In what order will you add the running plate and overlay to the resin casing? On the A4, the instruction suggested screwing and gluing the base etch and then soldering the upper overlay aftwards. However, that way you can only solder on the outside edge. I only screwed the base etch, added the overlay and soldered on the outside. Then I unscrewed it and soldered the inner edges, cleaned up then screwed and glued to the resin casing. It's maybe a bit belt and braces soldering both edges but that was my preference.

Cheers,

Peter

mickoo

Western Thunderer

Peter,

I will be removing the raised detail on the sand box when I fit the sand trap, we felt it better to have the flange on both, some people will just want the sandbox with the flange detail as their sand trap may not have the flange and vice versa, it's easy to cut one away, but not so easy to add if it's missing from both.

The W1 footplate overlays go on first as they form the ledge for the valance to fit to and also sit underneath the cab and firebox at the point where the raised edge ends. You solder the inside first then when you solder the valance that bonds the outside as well.

The casing has evolved, the original A4 had a thin edge to the base and rear, to allow a little more flexibility for fettling (and added protection during shipping) a sacrificial ledge was added. Simply mark the inside of the ledge in black marker and then carefully trim the ledge to give a good fit on the footplate, if you start to take off the black marked area then you have gone too far.

The only point where all of the ledge has to be removed is the very front to ensure a seamless transition between the buffer casings and the etched footplate top, elsewhere just enough ledge needs to be removed to give a good fit. The ledge on the inside of the walkway overlay is 0.4 mm so ideally you need your ledge on the casing to be just less than that. At the rear, just trim until it fits the cab front and meets the footplate at the front.

The critical part of the casing is the width between the overlays, by carefully trimming the ledge you should get a snug fit between the raised edges of the overlays. The casing material can be tweaked by immersion in hot water and the sides moved to make sure you have a good fit. Once happy, glue and screw and go make a coffee whilst the glue sets.

MD

I will be removing the raised detail on the sand box when I fit the sand trap, we felt it better to have the flange on both, some people will just want the sandbox with the flange detail as their sand trap may not have the flange and vice versa, it's easy to cut one away, but not so easy to add if it's missing from both.

The W1 footplate overlays go on first as they form the ledge for the valance to fit to and also sit underneath the cab and firebox at the point where the raised edge ends. You solder the inside first then when you solder the valance that bonds the outside as well.

The casing has evolved, the original A4 had a thin edge to the base and rear, to allow a little more flexibility for fettling (and added protection during shipping) a sacrificial ledge was added. Simply mark the inside of the ledge in black marker and then carefully trim the ledge to give a good fit on the footplate, if you start to take off the black marked area then you have gone too far.

The only point where all of the ledge has to be removed is the very front to ensure a seamless transition between the buffer casings and the etched footplate top, elsewhere just enough ledge needs to be removed to give a good fit. The ledge on the inside of the walkway overlay is 0.4 mm so ideally you need your ledge on the casing to be just less than that. At the rear, just trim until it fits the cab front and meets the footplate at the front.

The critical part of the casing is the width between the overlays, by carefully trimming the ledge you should get a snug fit between the raised edges of the overlays. The casing material can be tweaked by immersion in hot water and the sides moved to make sure you have a good fit. Once happy, glue and screw and go make a coffee whilst the glue sets.

MD

Yorkshire Dave

Western Thunderer

Simply mark the inside of the ledge in black marker and then carefully trim the ledge to give a good fit on the footplate, if you start to take off the black marked area then you have gone too far.

Stupid question - are you trimming the ledge from the inside or the outside to the black line?

P A D

Western Thunderer

Hi Mick,

You mention that "The casing material can be tweaked by immersion in hot water and the sides moved to make sure you have a good fit."

I assume that will apply to the A4 and if so, maybe a note in the instructions could be added.

On my build, the casing on the left side curved inwards slightly at the bottom edge, so did not butt up against the beading on the etch. I didn't think to imerse in in hot water and tweak it so I filled the gap later with cellulose putty.

Cheers,

Peter

You mention that "The casing material can be tweaked by immersion in hot water and the sides moved to make sure you have a good fit."

I assume that will apply to the A4 and if so, maybe a note in the instructions could be added.

On my build, the casing on the left side curved inwards slightly at the bottom edge, so did not butt up against the beading on the etch. I didn't think to imerse in in hot water and tweak it so I filled the gap later with cellulose putty.

Cheers,

Peter

Steph Dale

Western Thunderer

Mick, Pete,

The W1 uses a different resin and moulding process to the A4, but both can be adjusted through the use of hot water. The W1 casing is probably easier to work than the A4, but it certainly would have been worth it with the A4. So saying, a little filler to make up the joint works well too.

Steph

The W1 uses a different resin and moulding process to the A4, but both can be adjusted through the use of hot water. The W1 casing is probably easier to work than the A4, but it certainly would have been worth it with the A4. So saying, a little filler to make up the joint works well too.

Steph

mickoo

Western Thunderer

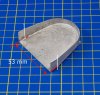

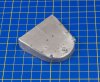

So, final update for the weekend, time for some me time next. I didn't get as far this week as I wanted, other things got in the way so I'm a few days behind where I wanted to be, none the less I'm still hoping to get the vast bulk done by months end.

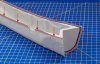

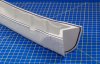

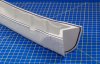

Yesterday and today was the footplate, just a few pieces of etch, but worth taking the time to bend and ensure it's a good fit between the two.

The two are not bonded together yet so there's a few gaps here and there and the casing needs a tweak in hot water in a couple of places, primarily to reduce the amount of filler needed. The old cab has been plonked on and it all fits just so, there's a couple of tweaks on the new cab to get it perfect, but for the moment I'm happy with what we have.

The important part is the arc, it has to flow, fit items on the chassis and the casing has to be flat on top, that which is flat and not the sloped section of the boiler. The firebox front stay support brackets are a smidge too tall and are lifting the footplate a little here which is causing the cab front to lift a little and lean back, again, minor tweaks to adjust before finally fixing it all in place.

Yesterday and today was the footplate, just a few pieces of etch, but worth taking the time to bend and ensure it's a good fit between the two.

The two are not bonded together yet so there's a few gaps here and there and the casing needs a tweak in hot water in a couple of places, primarily to reduce the amount of filler needed. The old cab has been plonked on and it all fits just so, there's a couple of tweaks on the new cab to get it perfect, but for the moment I'm happy with what we have.

The important part is the arc, it has to flow, fit items on the chassis and the casing has to be flat on top, that which is flat and not the sloped section of the boiler. The firebox front stay support brackets are a smidge too tall and are lifting the footplate a little here which is causing the cab front to lift a little and lean back, again, minor tweaks to adjust before finally fixing it all in place.

P A D

Western Thunderer

It's looking good Mick.

Thanks to you and Steph for the comments on the heating the resin.

Don't know why I never thought to give it a try, as that was the first thing I did with the Gladiator Duchess firebox. That resin was certainly tweakable with hot water treatment, but there were other dimensional errors that just spreading the sides did not help, hence the butchery that followed.

The resin drills quite nicely on the A4, certainly compared to the stuff that JLTRT used in their kits, so no complaints on that front.

Cheers,

Peter

Thanks to you and Steph for the comments on the heating the resin.

Don't know why I never thought to give it a try, as that was the first thing I did with the Gladiator Duchess firebox. That resin was certainly tweakable with hot water treatment, but there were other dimensional errors that just spreading the sides did not help, hence the butchery that followed.

The resin drills quite nicely on the A4, certainly compared to the stuff that JLTRT used in their kits, so no complaints on that front.

Cheers,

Peter

mickoo

Western Thunderer

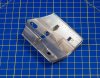

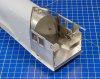

Onward, the real cab shell is all but done.

Slight miscalculation on the firebox extension and the gap will be closed on the boxed models, not that the gap will ever be seen once the roof is on, just one of those niggly things.

The cab is fixed to the casing but both are not finally fixed to the footplate as it needs to come off later for the ashpan to be fitted.

Backhead test fit. It's a tight fit so you need to leave one of the seats out until it's all painted and fitted to wriggle it in.

Profile.

Not bolted down yet so a couple of angles slightly out.

Slight miscalculation on the firebox extension and the gap will be closed on the boxed models, not that the gap will ever be seen once the roof is on, just one of those niggly things.

The cab is fixed to the casing but both are not finally fixed to the footplate as it needs to come off later for the ashpan to be fitted.

Backhead test fit. It's a tight fit so you need to leave one of the seats out until it's all painted and fitted to wriggle it in.

Profile.

Not bolted down yet so a couple of angles slightly out.

P A D

Western Thunderer

Hi Mick,

Wow that is clean! Or if you sneeze does it all fall apart?

Interesting that the backplate is a tight fit in the much larger W1 cab and that you need to leave one of the seats out. With the smaller A4 cab it goes in and out with no bother, even after adding strips to the top of the cab sides to facilitate gluing the roof on after painting.

Cheers,

Peter

Wow that is clean! Or if you sneeze does it all fall apart?

Interesting that the backplate is a tight fit in the much larger W1 cab and that you need to leave one of the seats out. With the smaller A4 cab it goes in and out with no bother, even after adding strips to the top of the cab sides to facilitate gluing the roof on after painting.

Cheers,

Peter

Overseer

Western Thunderer

To state the obvious, this is looking amazing. All this talk about fitting backheads into the cabs makes me wonder whether the kit boiler has been designed in its cold or operating condition. The few inches of extra length when at operating temperature is presumably all at the cab end so I assume the gaps between the bachead and the step boxes would reduce while in steam. Normally I wouldn't have even considered it as most models aren't accurate enough to worry about such things.

mickoo

Western Thunderer

The W1 cab is only larger in length, not width, in that aspect it is identical to the A4

There's a couple of reasons, so treading the thin line here I'll try to explain, most of the issues are to do with modelling so whilst it might appear 'wrong' it's just a combination of small things to make life easier when modeling.

The issue is the width of the cab, it should be 98" inside sheets, or in our terms 57 mm as near as matters. Unfortunately the resin casing where it meets the cab is a tad too narrow, shrinkage, whatever, it's lost in the mists of time. When the W1 casing was worked up this factor was considered but the work required to widen the firebox area was significant, it's not just the firebox, its the combustion chamber and boiler rear tube plate area as well.

To put this into context, we're talking about a 0.8 mm overall gain in width, it's that small, mind that would be large for some, however no one had even noticed on all the A4 kits sold, not that I'm aware of.

Taking the A4, the cab is the correct width as far as I can remember, it might even be a little wider, should be 57 mm between side sheets so the upshot of this is a slightly larger step between the cab front and firebox cladding.

When I worked up the W1 this step was simply not appealing, here's the real deal.

On the real engine it's about 3" and the A4 is pretty much the same.

So being as the casing is an unmovable object then the cab sides had to be altered, in our case I trimmed 0.3 mm off each side, it should of been more but this was the best of both worlds.

This now means the cab is 56.4 mm between side sheets, I suspect no one would ever have know if I hadn't of said so.

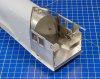

The next issue was the cab windows, one of my pet hates is glazing and how difficult it is to try and 'stick' it in after painting, so a different approach was taken, one where you can paint at will and then simply slide the glazing in, no gluing, sticking, faffing around, just drop it in.

To do this requires the sliding windows to have an internal recess, the real engine has two sliding windows so to keep the thickness down, one side of the sliding window was fabricated from 0. 4 etch with a 0.2 mm recess and a half etch 0.2 overlay.

The overlay isn't shown but the 0.2 mm recess is in the full thickness part, the window runners even had two individual tracks for the frames to slide in, it all worked until you painted it.

Back to square one, bring as the front window is rarely opened it was forsaken for a fixed window, this drops down between the cab sides and overlay and being as the cab sides are 0.4 mm thick then all should be well. The sliding window was then fabricated from two full thickness laminates which now leaves a nice 0.4 mm gap for the glazing and the reduction from two 0.6 mm windows to one 0.8 leaves a little more room for painting and still having working windows.

All of this means that the window frames put on a little weight, about 0.5 mm overall. Incidentally the front spectacle frames are still 0.2 mm gaped so care needed there when glazing.

The glazing slots can just be seen in this close up, spectacle and front 'fixed' side windows, the sliding windows are not fitted. You can also see where CCU stuck his oar in with the backhead extension plate, I've adjusted that on the master etch to close the gap, but as noted previously, you'd never see it once the roof was on.

So the upshot of all this is that I now have a 54 mm backhead trying to squeeze past a 53.4 mm opening between the window frames.

The end result however is, much better visuals twixt cab and casing, much easier glazing facilities and I think that kind of offsets the modelling compromises, others mileage may differ.

Regarding cleanliness, all of this is hidden soldering or surfaces that are easily cleaned afterward.

There's a couple of reasons, so treading the thin line here I'll try to explain, most of the issues are to do with modelling so whilst it might appear 'wrong' it's just a combination of small things to make life easier when modeling.

The issue is the width of the cab, it should be 98" inside sheets, or in our terms 57 mm as near as matters. Unfortunately the resin casing where it meets the cab is a tad too narrow, shrinkage, whatever, it's lost in the mists of time. When the W1 casing was worked up this factor was considered but the work required to widen the firebox area was significant, it's not just the firebox, its the combustion chamber and boiler rear tube plate area as well.

To put this into context, we're talking about a 0.8 mm overall gain in width, it's that small, mind that would be large for some, however no one had even noticed on all the A4 kits sold, not that I'm aware of.

Taking the A4, the cab is the correct width as far as I can remember, it might even be a little wider, should be 57 mm between side sheets so the upshot of this is a slightly larger step between the cab front and firebox cladding.

When I worked up the W1 this step was simply not appealing, here's the real deal.

On the real engine it's about 3" and the A4 is pretty much the same.

So being as the casing is an unmovable object then the cab sides had to be altered, in our case I trimmed 0.3 mm off each side, it should of been more but this was the best of both worlds.

This now means the cab is 56.4 mm between side sheets, I suspect no one would ever have know if I hadn't of said so.

The next issue was the cab windows, one of my pet hates is glazing and how difficult it is to try and 'stick' it in after painting, so a different approach was taken, one where you can paint at will and then simply slide the glazing in, no gluing, sticking, faffing around, just drop it in.

To do this requires the sliding windows to have an internal recess, the real engine has two sliding windows so to keep the thickness down, one side of the sliding window was fabricated from 0. 4 etch with a 0.2 mm recess and a half etch 0.2 overlay.

The overlay isn't shown but the 0.2 mm recess is in the full thickness part, the window runners even had two individual tracks for the frames to slide in, it all worked until you painted it.

Back to square one, bring as the front window is rarely opened it was forsaken for a fixed window, this drops down between the cab sides and overlay and being as the cab sides are 0.4 mm thick then all should be well. The sliding window was then fabricated from two full thickness laminates which now leaves a nice 0.4 mm gap for the glazing and the reduction from two 0.6 mm windows to one 0.8 leaves a little more room for painting and still having working windows.

All of this means that the window frames put on a little weight, about 0.5 mm overall. Incidentally the front spectacle frames are still 0.2 mm gaped so care needed there when glazing.

The glazing slots can just be seen in this close up, spectacle and front 'fixed' side windows, the sliding windows are not fitted. You can also see where CCU stuck his oar in with the backhead extension plate, I've adjusted that on the master etch to close the gap, but as noted previously, you'd never see it once the roof was on.

So the upshot of all this is that I now have a 54 mm backhead trying to squeeze past a 53.4 mm opening between the window frames.

The end result however is, much better visuals twixt cab and casing, much easier glazing facilities and I think that kind of offsets the modelling compromises, others mileage may differ.

Regarding cleanliness, all of this is hidden soldering or surfaces that are easily cleaned afterward.

Last edited:

P A D

Western Thunderer

Hi Mick,

Thanks for the very detailed explanation. Sorry to put you to this much trouble in answering my question.

I would agree that the compromises you have made are offset by the benefits gained. Let's face it building model locomotives in this scale is one big compromise from start to finish. As you have said, if you hadn't admitted the compromise, nobody would ever have noticed. As far as I am concerned, if at the end of the build it looks right, then it is right, even if it isn't . Others of course have a different viewpoint, but each to their own.

Cheers,

Peter

Thanks for the very detailed explanation. Sorry to put you to this much trouble in answering my question.

I would agree that the compromises you have made are offset by the benefits gained. Let's face it building model locomotives in this scale is one big compromise from start to finish. As you have said, if you hadn't admitted the compromise, nobody would ever have noticed. As far as I am concerned, if at the end of the build it looks right, then it is right, even if it isn't . Others of course have a different viewpoint, but each to their own.

Cheers,

Peter

mickoo

Western Thunderer

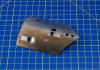

I decided enough was enough with the backhead, it was only 0. (whatever) over width so surely something could be done.

The casting has very thin sidewalls, so filing them back wasn't an option, it took a while for the solution to make it slowly to the fore and here's what I ended up doing, instructions also duly amended.

First thing was to make two thin cuts 9 mm long up the sides where they meet the front, red lines.

Then I re-bent the side pieces at the white lines, there's already an inward kick here but I just moved the bend up a little higher, about a mm or so, straightened it all up and made sure the overall width was less than 53 mm. The saw cut was then flood filled with a large blob of 100°C solder at the rear.

Flipping it over it was a case of trimming the front at the bottom where it was too wide to meet the new side profile and then dress accordingly.

It barely looks any different that the original, but importantly, drops in vertically past the windows, the width reduction once in place is hardly noticeable.

This now means I can add the foot rests and reverser column and still get the backhead in and out

The gap at the heel is hardly noticeable tucked up under the dias and foot rests.

Right now back to what I was supposed to be doing, handrails and casing fittings.

The casting has very thin sidewalls, so filing them back wasn't an option, it took a while for the solution to make it slowly to the fore and here's what I ended up doing, instructions also duly amended.

First thing was to make two thin cuts 9 mm long up the sides where they meet the front, red lines.

Then I re-bent the side pieces at the white lines, there's already an inward kick here but I just moved the bend up a little higher, about a mm or so, straightened it all up and made sure the overall width was less than 53 mm. The saw cut was then flood filled with a large blob of 100°C solder at the rear.

Flipping it over it was a case of trimming the front at the bottom where it was too wide to meet the new side profile and then dress accordingly.

It barely looks any different that the original, but importantly, drops in vertically past the windows, the width reduction once in place is hardly noticeable.

This now means I can add the foot rests and reverser column and still get the backhead in and out

The gap at the heel is hardly noticeable tucked up under the dias and foot rests.

Right now back to what I was supposed to be doing, handrails and casing fittings.

Last edited: