Well, a nice sunny day, and on a Wednesday too. I took the opportunity to get some better photos.

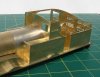

The cab inside splashers are best detailed before soldering them in place. Trimming all the platework to fit is a bit tricky as they will need a bit of filing to fit in all planes, and access is awkward.

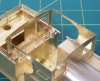

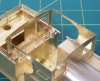

Some bunker top detail:

You can see the replacement band at the boiler/spectacle plate join. Having thought about it, I will separate all similar boiler/firebox joins as a matter of course. I think it will be much easier to roll/form them separately.

Clearly I have put the sides on, and that doesn't half change the appearance. I have not yet soldered the top of the panel to the cab rear as I wanted to see where the roof fitted first to see how much space I have to strengthen the join. It's rather flimsy without any strengthener at the moment. I also discovered that not all Radials had the handrail ahead of the cab sheets. It's a good job I hadn't drilled the hole in the footplate to receive the bottom of the handrail!

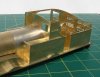

And a profile picture of progress:

Cheers,

Richard