Hello Ian, all,

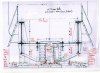

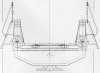

as the frames above are for three locos it shows both left and right frames but the way is about the same for any frames build.

1] drill the bearing holes to suit the bearings (do this even if your going to use sprung horn blocks), I'm going to use sprung horn blocks so I've only drilled the front and rear bearing holes.

2] Fit bearings (don't solder them) in the holes, add second set of frames and clamp them together.

3] On the frames above I think that I soldered them at the following points, top front, above the front bearings, half way between the front and middle bearings, above the middle bearings, half way between the middle and rear bearings, top rear of the frames, bottom rear corners, on the bottom edge with all of the bits in the way close to the front and rear edges of the horn guide cut-outs, if you can try and solder about half way between them as well, then bottom front corners.

4] Remove the bearings.

5] Cut off all the bits off the bottom of the frames that you don't want.

6] Clean up all of the edges.

7] If using sprung horn guides cut out the front and middle bearing plates. Leave the rear one in place for setting the wheel base.

8] Drill the holes for the brake pivot points, pick-ups Etc.

9] Un-solder the laminations apart (this can be fun NOT), if it's only two thickness I tend to use a soldering iron and a craft knife. For these I think that I'll use a blow torch to split them.

10] Debure all edges and holes and remove any solder from the faces of the plates.

The spring detail that I removed from the frames, to do this I used a reinforced cutting disc,

The frames after cleaning up the edges and before cutting out the bearing plates,

Sorry for the long post but I was asked,

OzzyO.