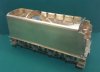

Having considered the information provided by Mickoo, and studied as many photos as I could find of the A3 non corridor tender, I have decided to build it as it comes. Below is an example of why.

It is a crop from "The Book of the A3s" .

Comparing the back of the tender with the etching, the curve is more pronounced so I'm sure it's taller. At the front I believe the height is somewhere between that of the A4 tender as build, and as later cut down when fitted to the A3. Therefore there would be more butchery of the etches required to convert it, along with making a new rear plate.

Mick, sorry to have wasted your time, it was not intentional. Maybe something for you to consider for the future, would be to add additional etchings to make both tenders from the kit.

Anyway on with the build.

I have completed the tender frame subsection apart from fitting the buffers, which is not possible as they come.

As can be seen through the holes in the buffer beam, the frames preclude fitting the nice sprung buffers provided. I note that Mick has written a thread on converting the buffers to being self contained and I may take that option. In the instructions, Mr. Finney suggests elongating the holes to move the buffers inwards! I think not, and have parked them for now and will come back to them later. I would be interested to know how Richard (of the tricky variety) did his.

Slight hiccup with the buffers aside, I'm still bloody impressed with how precise everything fits with this kit.

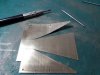

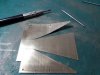

Here's the tank sides after bending the curve at the top.

Again I used my brother Mick's hefty bending bars to make the curve. The instructions suggest using a 1/4 inch rod which I don't have so Mick's toy was utilised. There are half etch lines on the inside of the curve, so I lined up the first three one at a time starting with the lowest, and made a slight bend using a suitable length of wood. I then reversed the piece and lined up the top half etch line and then made the rest of the curve.

Worked a treat and only a little rubbing down on the outside of the curve will be required to remove any witness marks.

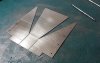

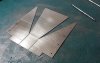

After that various parts need the rivets punching out before assembly of the tank begins . Again this was done with my trusty auto centre punch. The rivets were then counter punched to remove the distortion induced in the workpiece by the punch, as described earlier.

It's best to only punch a small number of rivets at a time before counter punching. Here's one of the bunker sides after punching all the rivets in one go. It is "well bent".

Counter punching with the jewelry tool removes it but j think it's better not to induce this level of distortion.

Here it is completed after punching smaller sections and then counter punching before punching more rivets.

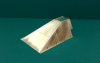

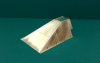

Here it is after bending and soldering.

Here are some of the bulk head parts after punching the rivets. Some of them are half etched.

Here's the rear plate with the laminate in place.

And the other side with the handrails, steps and lamp brackets added.

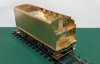

This is the underside tank top laminated from two parts.

And the topside with the lifting rings and brackets added.

Cheers,

Peter