Mr Grumpy

Western Thunderer

The lamp irons and roof are now fitted and the home straight is in sight!

I'm hoping to spend some time completing and possibly priming the chassis tomorrow.

The van is sitting a little high as I haven't added the weights yet.

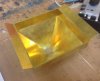

Mark JJ has kindly supplied me with some liquid lead which will go into the sandbox bench, and I will use curtain weights in the cabin.

I'm hoping to spend some time completing and possibly priming the chassis tomorrow.

The van is sitting a little high as I haven't added the weights yet.

Mark JJ has kindly supplied me with some liquid lead which will go into the sandbox bench, and I will use curtain weights in the cabin.