Nick Dunhill

Western Thunderer

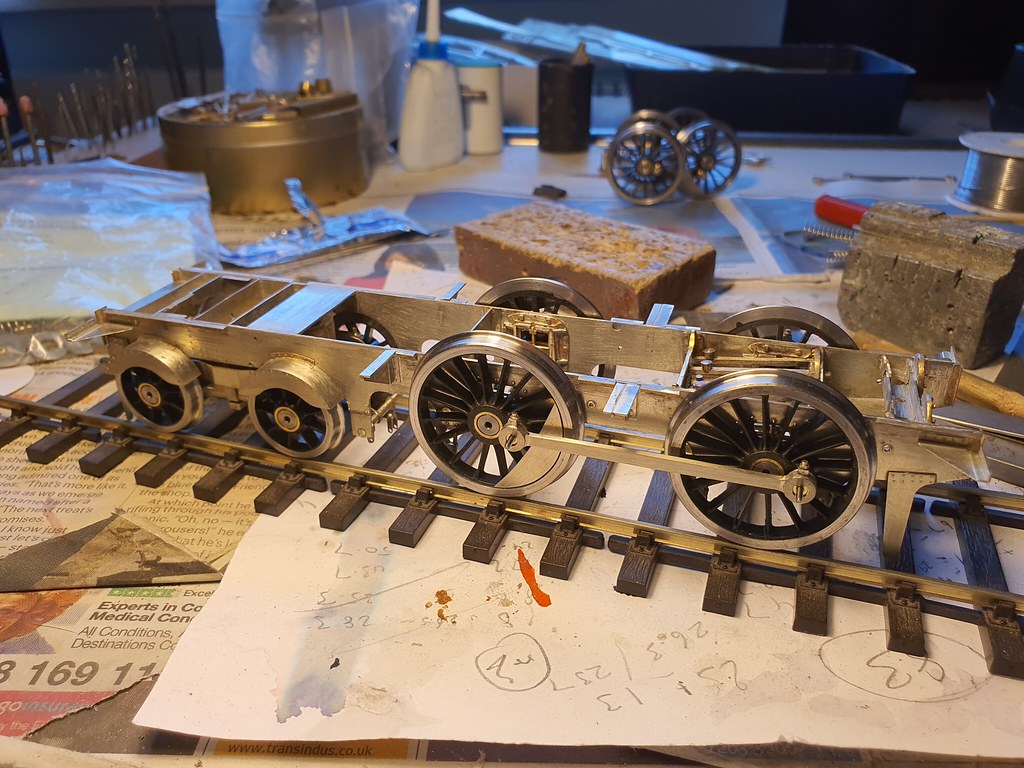

....a big week with the Wrexhams, I've been working on all the mundane bits and pieces that are often overlooked.

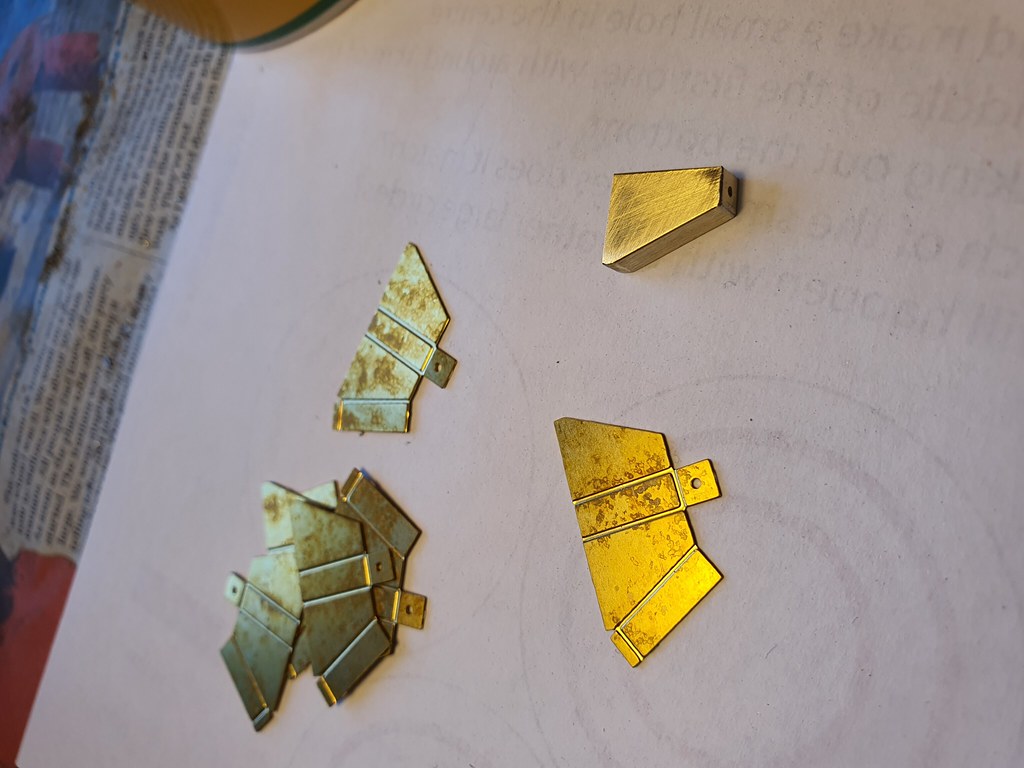

First I completed a bit more work on the firebox bottom and ashpan. The damper doors were detailed with straps and hinges. The rest of the detail will be added when they are installed.

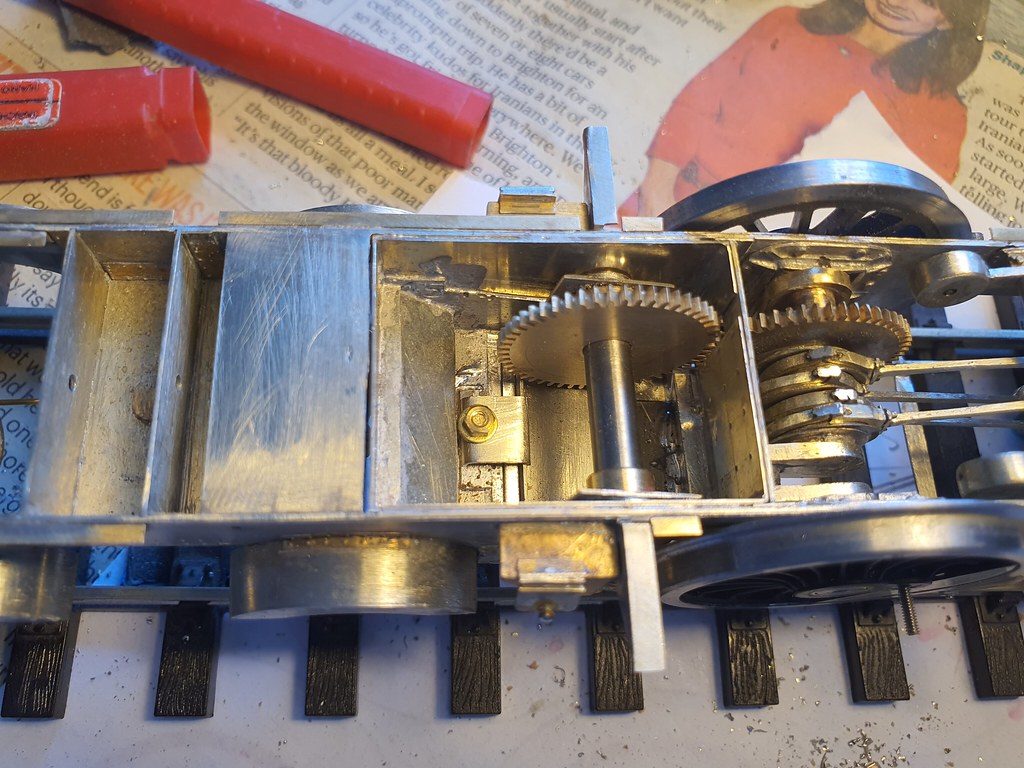

Then I moved on to the hornguides. I couldn't find any commercially available cast ones. They're all the wrong pattern or too large to fit between the slidebars and frame, or the crank webs and frame. I considered scratchbuilding some but in the end opted for some Gresley etchings from the Finney7 Coop. They have the wedge adjusters so are handed as prototype, and could be modified relatively easily. The horncheeks are much reduced in height and I added wedges from 1 mm square rod and all the webs.

I added some 14BA screws and nuts as height adjusters. They're brass items which can be soldered up when all is level.

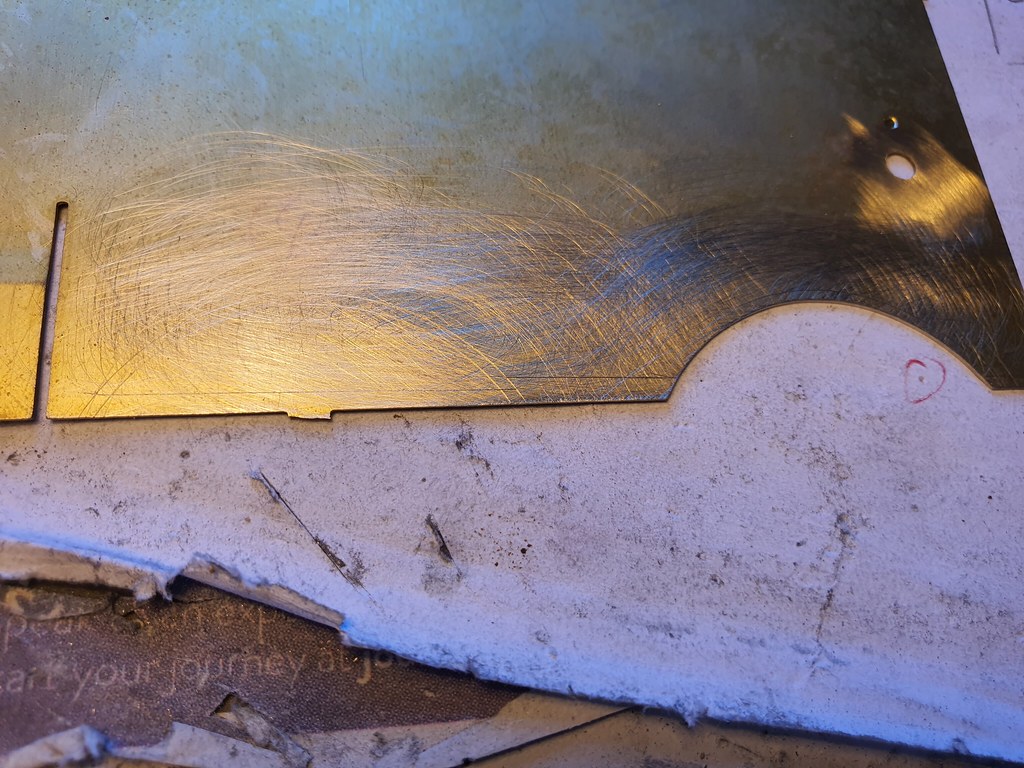

I like self contained buffers as the fixing screws don't interfere with the gusset structures that support the buffer beams from behind. The semi tapered GWR Dean (?) buffers were an excellent match, and I bought sets of them from Haywood Models. The GWR version of the buffers have a tread on the stocks which my locos don't, but being white metal they are easy to file off.

The fixing studs and nuts are represented by a cast pip that's just a bit lame! I filed them off and will add some fake fastners from GHW-Modelbauversand in Germany. They're cheaper than the ones from Scale Hardware in Florida as we don't have to pay import duty or VAT on them for the time being (thanks Brexiteers!)

My plan was to drill out the buffer bodies all the way through and cut off the unnecessary housing on the rear. The stocks were already partly drilled out to 2 mm, so I just continued on through. The buffer heads have a shank that is much less than 2 mm at the head. I decided to sleeve the shanks out to stop the heads rattling about in them. The sleeve conveniently holds the buffer spring captive inside the stock. I made some guide/stops for the inside of the stocks, and glued them in place using a drill and tape repurposed as a locating tool.

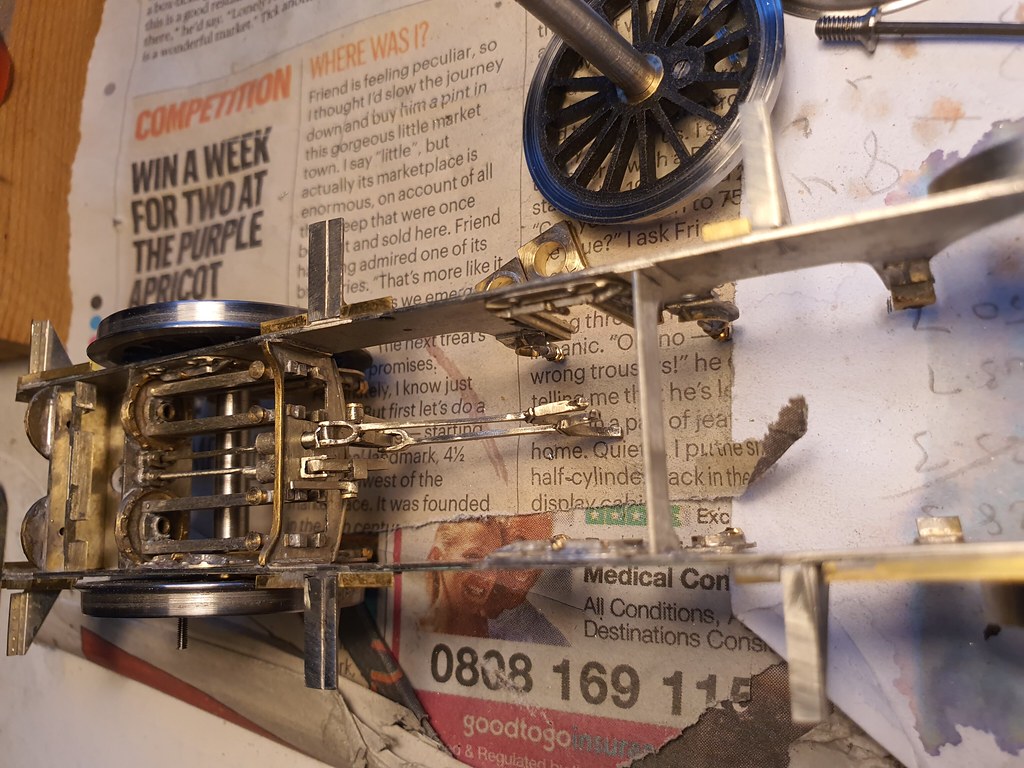

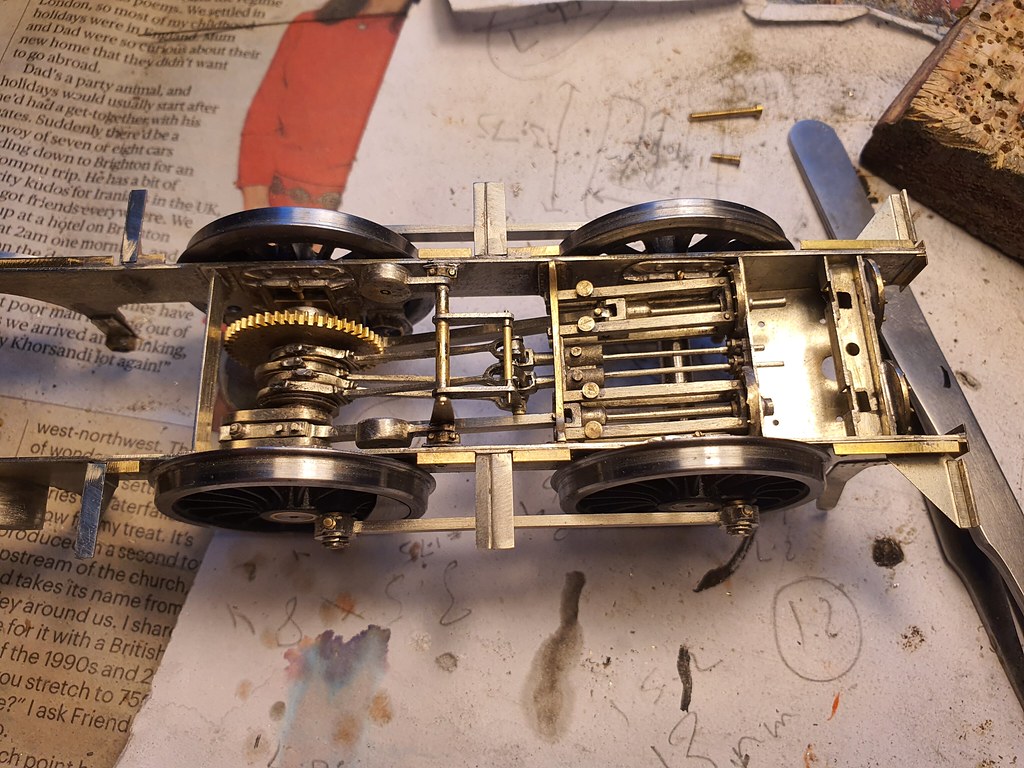

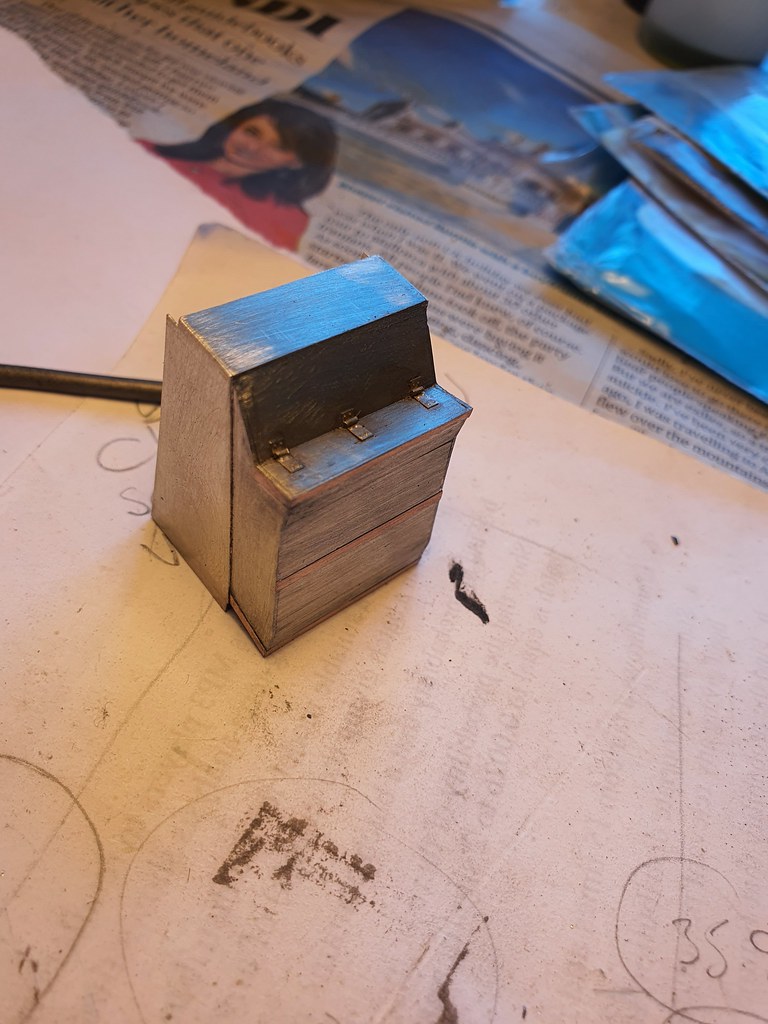

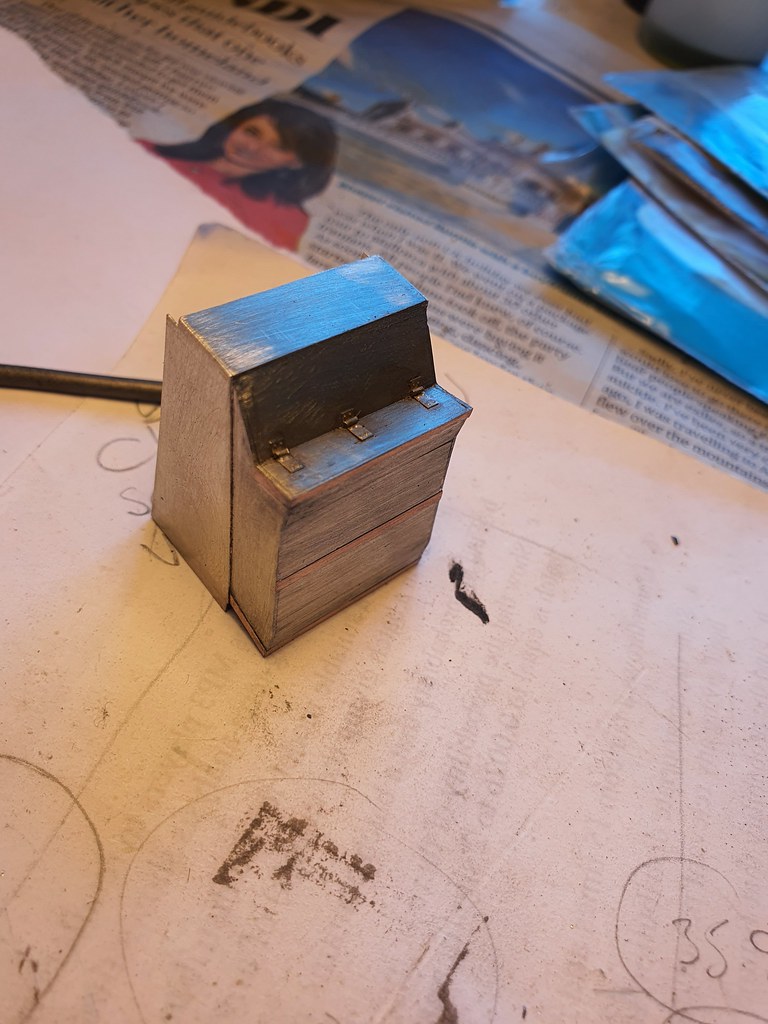

I went on to make some spring hangers next, 16 of them and handed. The photo shows how I did it.

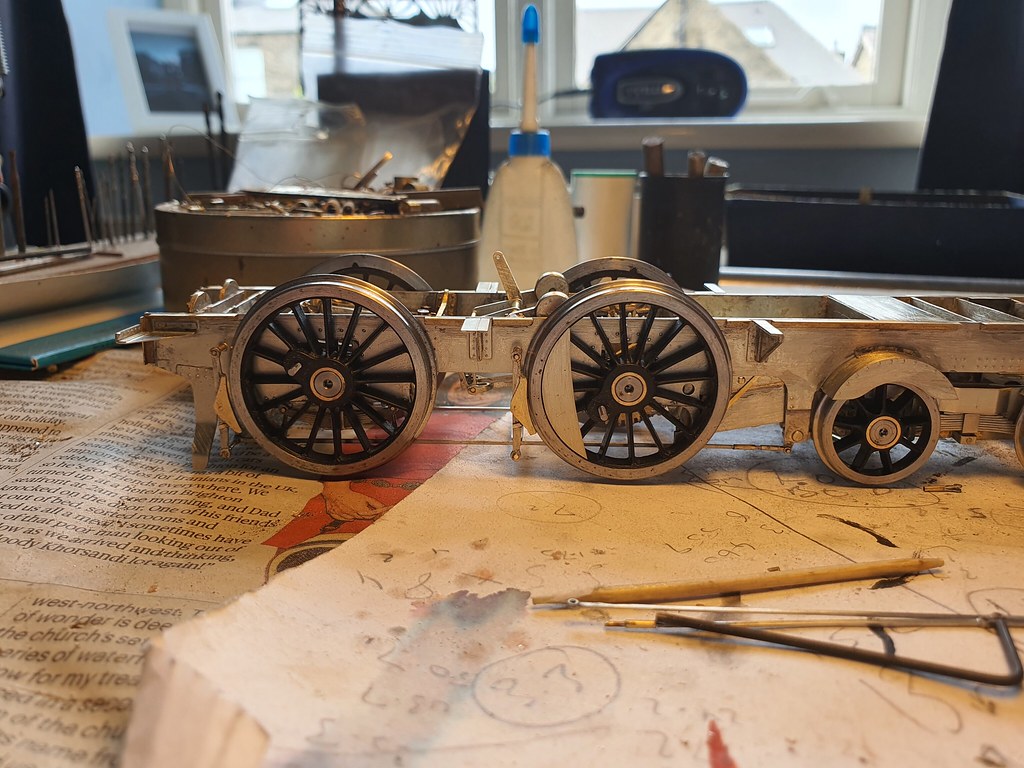

They were a lot of effort but will look good on the model. They are on show through the spokes too.....

Hopefully next week I can finish the springs, build some coupling rods and instal everything else......

First I completed a bit more work on the firebox bottom and ashpan. The damper doors were detailed with straps and hinges. The rest of the detail will be added when they are installed.

Then I moved on to the hornguides. I couldn't find any commercially available cast ones. They're all the wrong pattern or too large to fit between the slidebars and frame, or the crank webs and frame. I considered scratchbuilding some but in the end opted for some Gresley etchings from the Finney7 Coop. They have the wedge adjusters so are handed as prototype, and could be modified relatively easily. The horncheeks are much reduced in height and I added wedges from 1 mm square rod and all the webs.

I added some 14BA screws and nuts as height adjusters. They're brass items which can be soldered up when all is level.

I like self contained buffers as the fixing screws don't interfere with the gusset structures that support the buffer beams from behind. The semi tapered GWR Dean (?) buffers were an excellent match, and I bought sets of them from Haywood Models. The GWR version of the buffers have a tread on the stocks which my locos don't, but being white metal they are easy to file off.

The fixing studs and nuts are represented by a cast pip that's just a bit lame! I filed them off and will add some fake fastners from GHW-Modelbauversand in Germany. They're cheaper than the ones from Scale Hardware in Florida as we don't have to pay import duty or VAT on them for the time being (thanks Brexiteers!)

My plan was to drill out the buffer bodies all the way through and cut off the unnecessary housing on the rear. The stocks were already partly drilled out to 2 mm, so I just continued on through. The buffer heads have a shank that is much less than 2 mm at the head. I decided to sleeve the shanks out to stop the heads rattling about in them. The sleeve conveniently holds the buffer spring captive inside the stock. I made some guide/stops for the inside of the stocks, and glued them in place using a drill and tape repurposed as a locating tool.

I went on to make some spring hangers next, 16 of them and handed. The photo shows how I did it.

They were a lot of effort but will look good on the model. They are on show through the spokes too.....

Hopefully next week I can finish the springs, build some coupling rods and instal everything else......