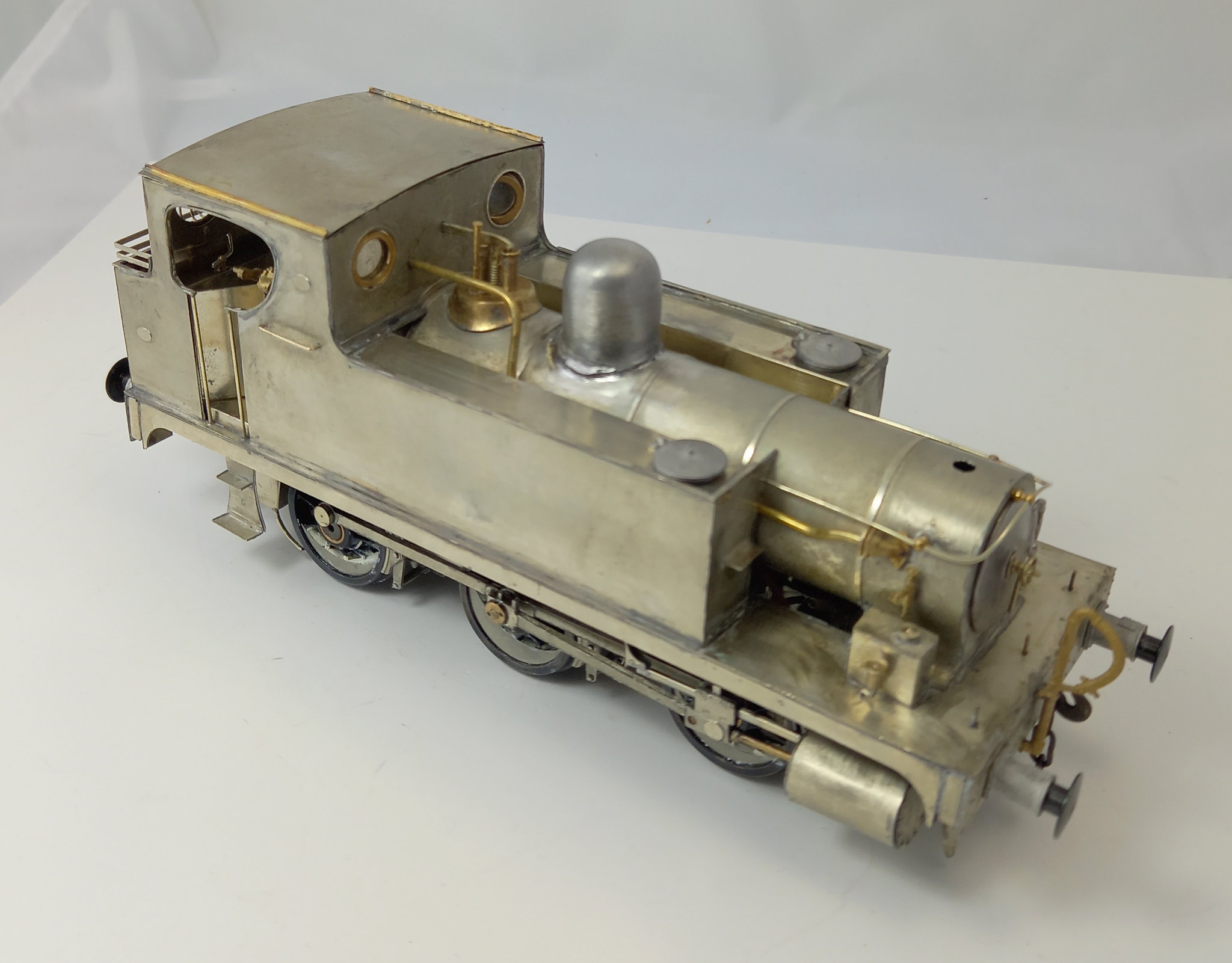

A couple of sessions this weekend, have seen most of the brass castings and the backhead finished and secured in place.

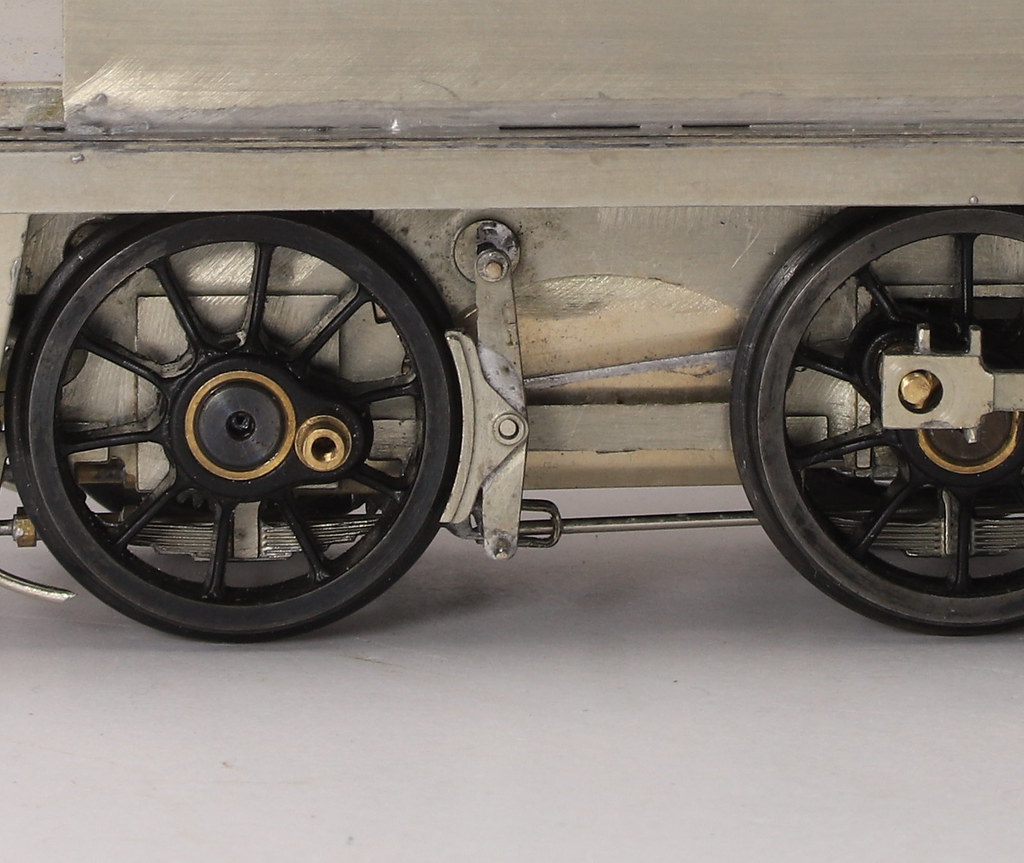

Prior to doing that I had to make a cab floor or rather the front section of the cab floor because my replacement backhead fell through the section that’s not provided in the kit when I tried it in place.

I added a couple of 2mm wide strips to the edges of the cab splashers and then soldered the additional cab floor to that which brought it to the same height as the rest of the cab floor.

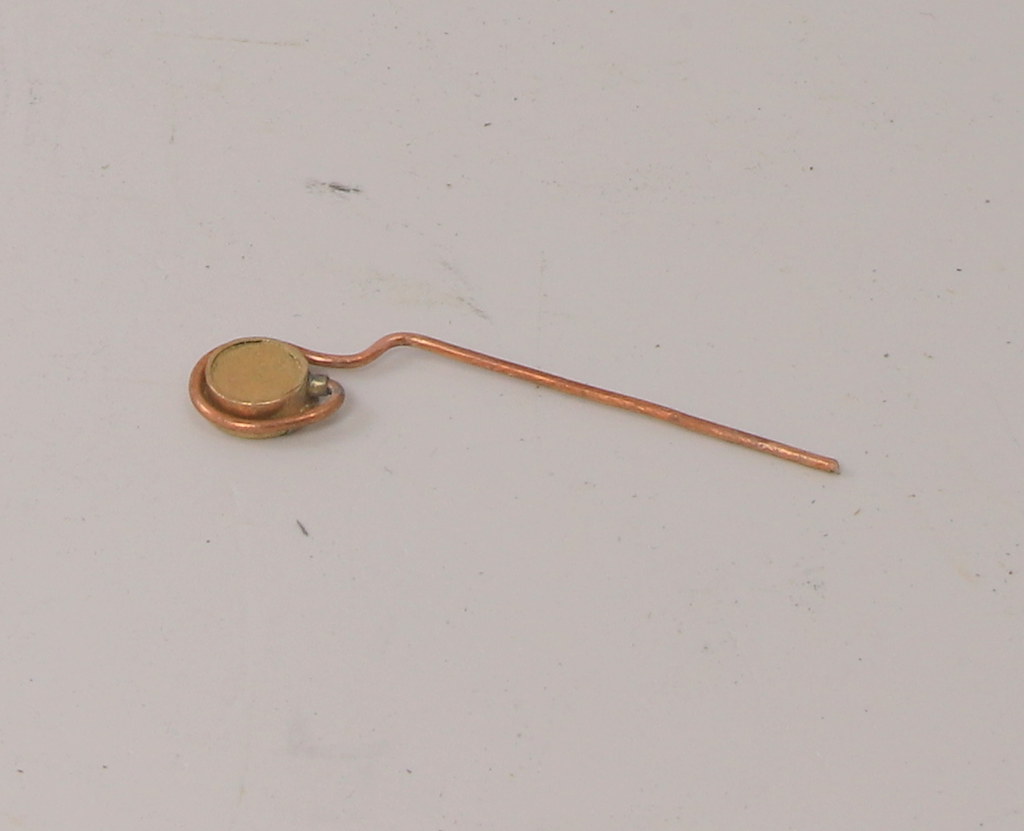

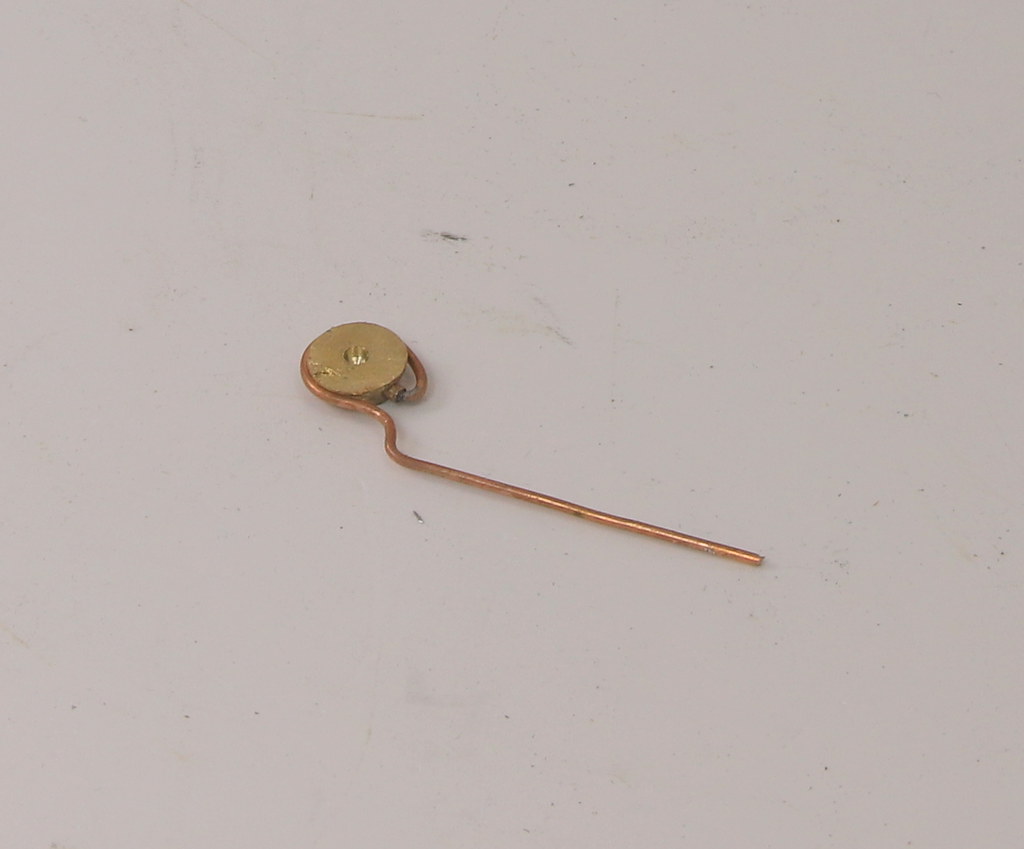

After making the floor it gave me another option to secure the backhead so I made the back head and the cab gauges removable to ease the job of painting.

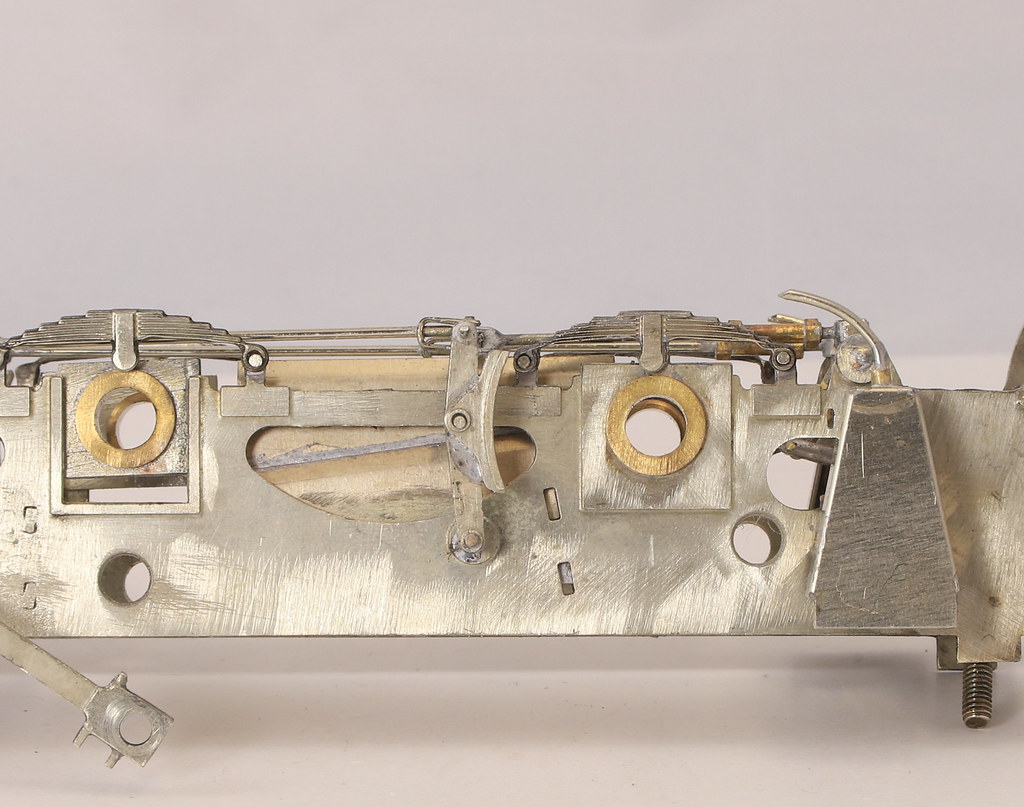

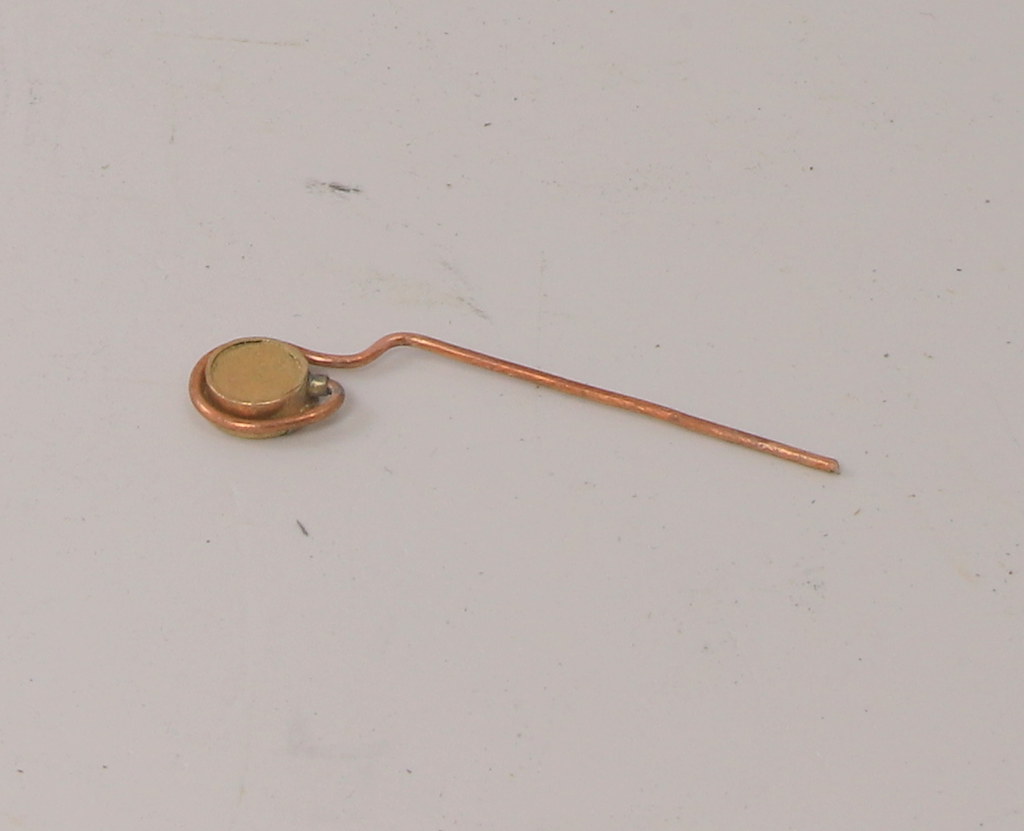

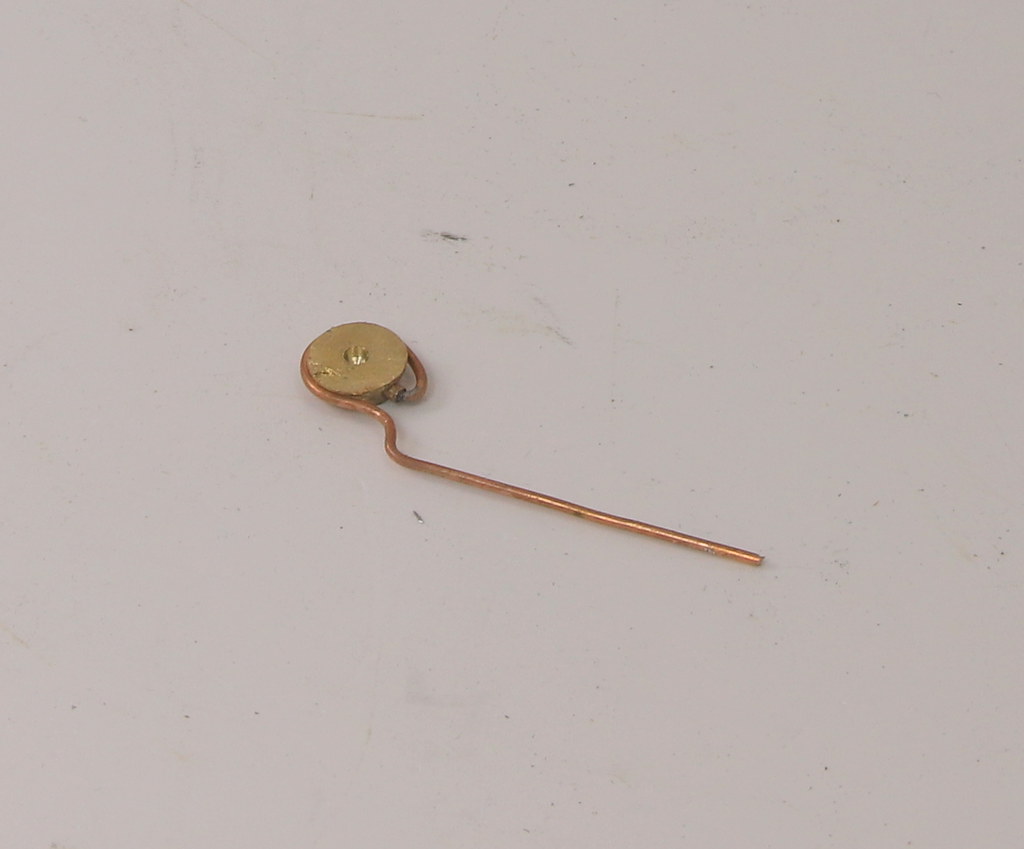

I folded a small piece of 10thou nickel into a U shape with a short leg to the front and drilled a hole for a 10ba nut. The idea of the U shape is to add a bit more strength to what is relatively thin sheet.

I added a short length of tube in the corner of the cab front and splasher and the tail of the pipe from the gauge locates into it with the back of the dial fitting over the peg where the vacuum ejector pipe enters the cab. Not strictly prototypical I am sure but it means that after painting a small dab of glue will secure it in place.

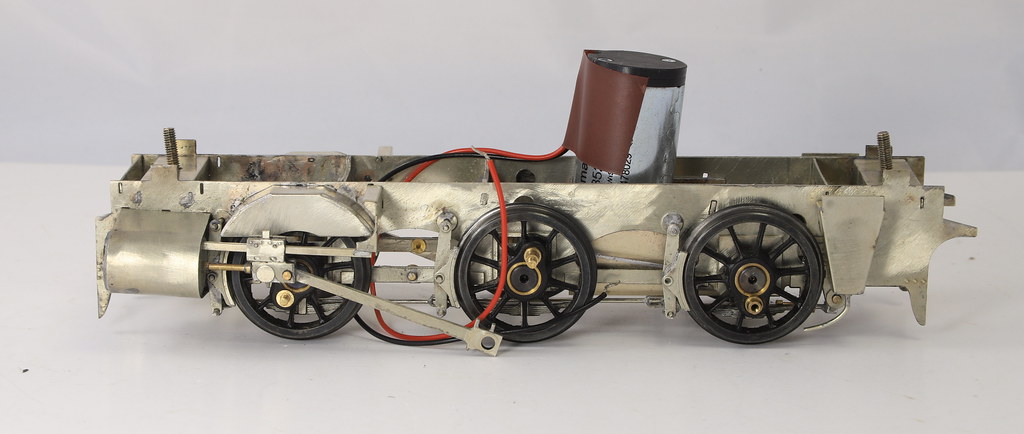

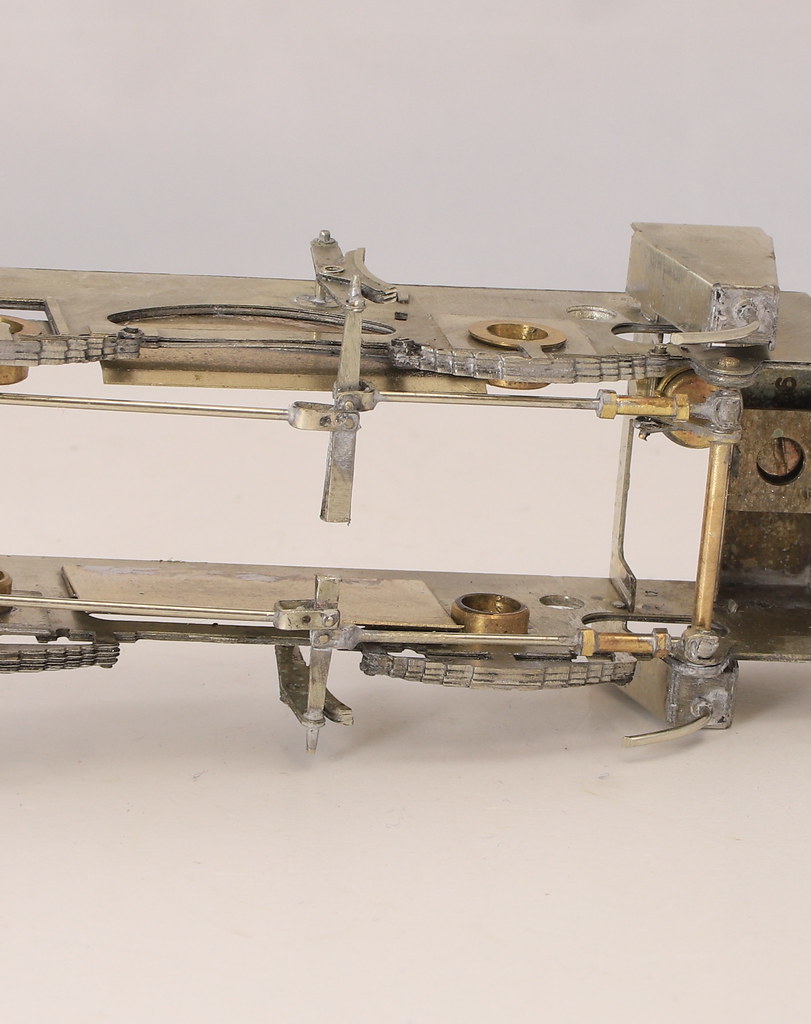

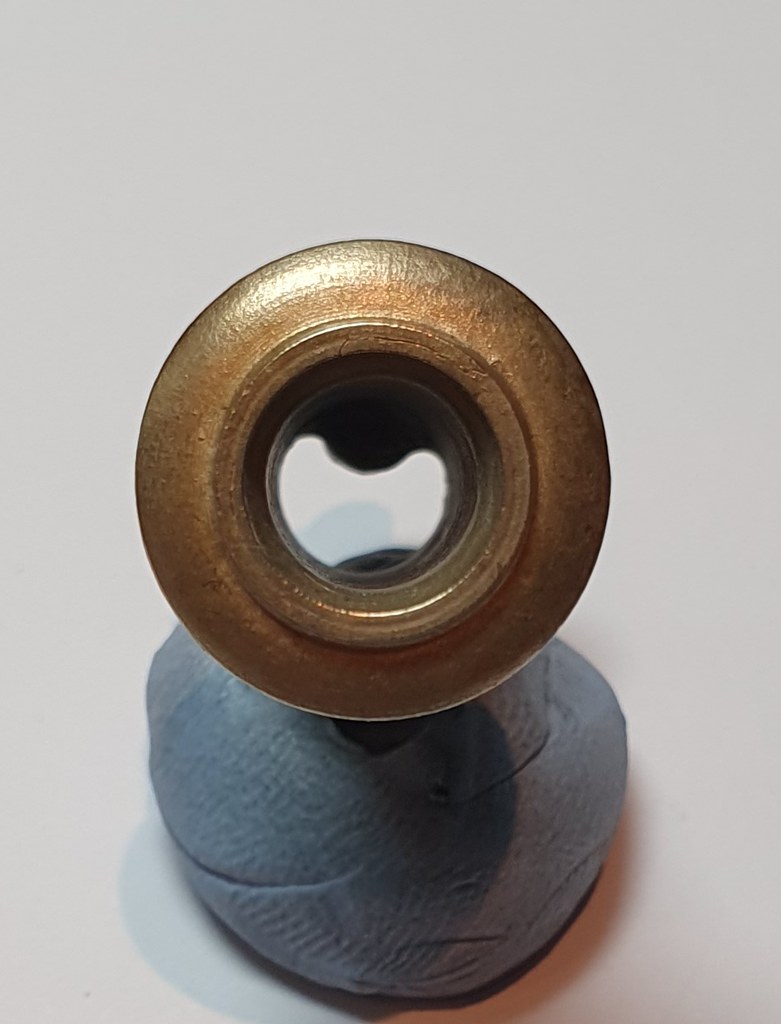

A few general shots of the smokebox details which is where most of it seems to be on this loco.

The clack valve is one of Jim McGeown’s from his most useful sprue of Clack and elbow castings as is the vacuum ejector elbow on the other side.

The lubricators on the smokebox are Laurie griffin and the small pipe and fitting is scratch built from tube, rod and scrap etch.

The rather nice turned whistle came with the kit and is without doubt the best fitting supplied.

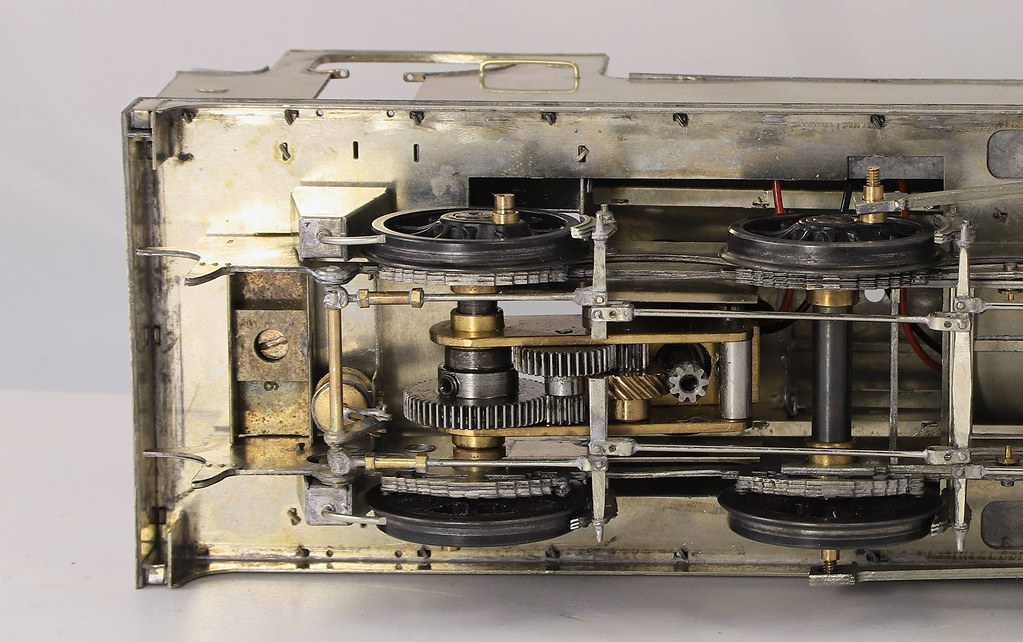

Still to fit are vacuum pipes and the whitemetal fittings – buffers, dome and chimney, then balance weights and some lead in the side tanks before track testing.

The end is most definitely in sight.