Peter Insole

Western Thunderer

I must confess that I have for some time been terribly suspicious of all the new technology that is available to the hobby. I felt that it would ultimately diminish skill attainment levels in all areas of creative model making. How could I have been so shamefully arrogant and misguided, especially considering that I have been personally involved in the development of laser cut kits in recent years?!

Notwithstanding my subsequent conversion, that foolish attitude provided the catalyst for starting this project in the first place! Indeed, it was an increasingly desperate search for traditional materials that led me to meet and make new friends at a local S7 group. There is so much to learn and I would encourage anyone to join up with other enthusiasts wherever possible to share experience and knowledge. Mind you, it hasn't stopped me from being a prize idiot, it is just nice to be amongst folk that are so tolerant (so far) and prepared to put up with my tendency to spout off, be too critical or impractical!

So yes, I can be a bit naughty, but this time I have exceeded myself with this commission! I not only viewed it as a last opportunity to fully stretch myself and make something entirely scratch built in a large scale, but old family connections with Wadhurst in Sussex presented a perfect excuse for re-living fond memories of the Southern Region in the early 1960's. The process has not only created a rod for my own back, but a massive hit on an old friend and customer's wallet!

Anyway, to the brief: I was asked to model a station on the aforementioned Southern, a small country type suitable for through main line as well as local traffic but particularly 3rd rail and on a 2-BIL route! When searching for a candidate, I recalled a book that I had acquired with a token when still at school; Peco Publications' Southern Stations. Studying the pictures and then looking on-line for surviving structures led me to Bagshot, the only one that was not too big or complicated and was still largely intact for measuring. A twist of irony (and one of several as it has turned out) was that included were three delightful photographs of the place. I had not previously been aware of, nor ever visited, but those shots had been the very reason for selecting the book all those years ago. It is difficult to describe the peculiar sensation of alighting from a train as an older, creakier self on a mission, directly back into my childhood imagination!

Now wishing that I had been a bit more prepared to consider laser cutting for the bulk of the structure, I rather too eagerly committed myself, or maybe I should be? That was two years back, and still a way to go!

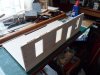

I have kept a WIP photo diary, so will start with the Porters' Room test piece and describe/explain reasoning, or the lack of, later!

Pete.

Notwithstanding my subsequent conversion, that foolish attitude provided the catalyst for starting this project in the first place! Indeed, it was an increasingly desperate search for traditional materials that led me to meet and make new friends at a local S7 group. There is so much to learn and I would encourage anyone to join up with other enthusiasts wherever possible to share experience and knowledge. Mind you, it hasn't stopped me from being a prize idiot, it is just nice to be amongst folk that are so tolerant (so far) and prepared to put up with my tendency to spout off, be too critical or impractical!

So yes, I can be a bit naughty, but this time I have exceeded myself with this commission! I not only viewed it as a last opportunity to fully stretch myself and make something entirely scratch built in a large scale, but old family connections with Wadhurst in Sussex presented a perfect excuse for re-living fond memories of the Southern Region in the early 1960's. The process has not only created a rod for my own back, but a massive hit on an old friend and customer's wallet!

Anyway, to the brief: I was asked to model a station on the aforementioned Southern, a small country type suitable for through main line as well as local traffic but particularly 3rd rail and on a 2-BIL route! When searching for a candidate, I recalled a book that I had acquired with a token when still at school; Peco Publications' Southern Stations. Studying the pictures and then looking on-line for surviving structures led me to Bagshot, the only one that was not too big or complicated and was still largely intact for measuring. A twist of irony (and one of several as it has turned out) was that included were three delightful photographs of the place. I had not previously been aware of, nor ever visited, but those shots had been the very reason for selecting the book all those years ago. It is difficult to describe the peculiar sensation of alighting from a train as an older, creakier self on a mission, directly back into my childhood imagination!

Now wishing that I had been a bit more prepared to consider laser cutting for the bulk of the structure, I rather too eagerly committed myself, or maybe I should be? That was two years back, and still a way to go!

I have kept a WIP photo diary, so will start with the Porters' Room test piece and describe/explain reasoning, or the lack of, later!

Pete.

Last edited: