ChrisM

Active Member

Hello everybody,

Hopefully you don’t mind me jumping straight in here, rather than heading through the new members section, but it made sense to keep everything in one place... so by way of an introduction, I’m Chris, half of the double act that put together the various bodgings that appear on otcm.wordpress.com

Despite never having previously posted on WT, I’ve been a lurker for a couple of years and wanted to share progress on my cameo competition entry through the forum, it feeling the best and easiest place to get feedback and take other people’s ideas on board to hopefully improve the final outcome. I planned on making the first post in November last year so am running a little late on the initial update - I’ve actually been trying to maximise time on the layout with some ‘little and often modelling’ rather than looking at forums hence not getting round to it...

I’ve spent the last 5 or so years in a bit of a layout drought, not having actually produced something single handedly since my mid teens - looking to move out my parents house and not knowing what space would be available for a layout essentially put layouts on the back burner although I spent plenty of time working on rolling stock. Myself and Oly then built Stoating Bank in a bit of a rush, and took it out to a few shows, but since then, despite now knowing what space I have and several false starts nothing has really appeared. The announcement of this competition, complete with deadline, seemed the ideal opportunity to get myself in gear and actually build something!

Now, onto the layout - from the outset I wanted the layout to be a little different, portraying a run down industrial scene in an early 1970’s winter. If possible the industrial railway would be supplemented by some BR action, but only if it didn’t result in things looking too cramped or too much compromise. This concept developed into an early plan for a small set of interchange sidings half way along an industrial line, with a couple of sidings serving various steel works buildings. A scale plan of this proved it fitted although somewhat cramped, into the 5ft space I had given myself to work in.

The only flaw with this was that upon measuring the car just prior to constructing the boards, it became obvious only a 4ft 6in board would fit, and as such the baseboard was built to this size - I certainly didn’t want to go down the van hire route for something no more than 10ft in total length, and this seemed to undermine the cameo concept somehow. Putting the plan onto the shortened board did not work at all, and it was back to the drawing board for a rethink.

Several ideas, geographical locations and plans later I finally found something I was happy with and seemed to offer sufficient operating potential. This is key to me getting any enjoyment out of operating, every movement must have a purpose and be carried out in a prototypical manner - you can’t run a ‘coal train’, but you can run 8M27, the 13.27 loaded coal from A to B.

The original plan had gone under the working title of ‘Bottom Works’, representing the lower half of a steelworks complex, and identifying the layout, hopefully, as being set in Yorkshire. I was keen to keep this name going but as the new plan no longer featured any works buildings (a cameo sized baseboard fills pretty quickly when steelworks buildings are on the agenda!) I added sidings to the name, what is modelled supposedly being the one time junction for a line serving a plant at a lower level.

I think the finished plan is a bit of a cross between a layout in its own right and a ‘bitsa’ - while it doesn’t try to portray a small part of a larger scene, it is totally reliant on the imaginary scene around it to work, so what am I modelling?

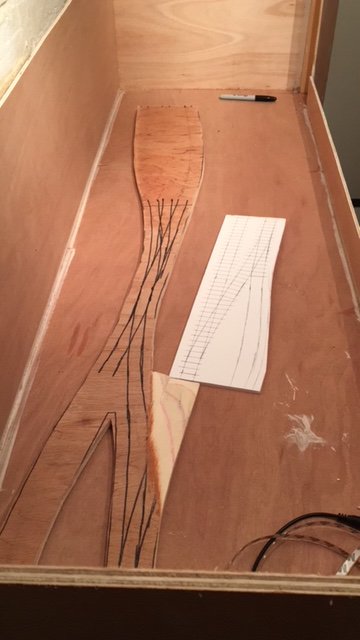

Towards the rear of the layout there is a freight only branch running from a set of exchange sidings to a small steel processing plant (the exact specification of this and the traffic it creates is still TBC...) This is maintained and operated by BR, with BSC movements having running powers. Mid way along the layout this connects with a BSC internal railway system serving a secondary entrance to a coking plant (assumed to have originally been part of the steel companies property portfolio) and there are a couple of loops for the interchange and holding of traffic. There are then a couple of sidings and a lifted line, formerly heading off to the previously mentioned Bottom Works (another area of the former steelworks). The whole concept is heavily inspired by the Stocksbridge Railway. Hopefully this overhead shot from before too much had happened gives an idea of the plan:

There is nothing special about the construction methods, the boards are a mixture of 6mm and 9mm ply - I’m certainly not a carpenter and as such the boards are a long way from perfect, but will hopefully do the job. (I didn’t want to end up restricted by the constraints of an off the shelf kit board, and was keen to follow the advice of Iain in the book with all the board components built in from the start.) In hindsight I wish there was a bit more 9mm in it for some added strength, but it is nice and lightweight... the lighting pelmet is removable at present to ease construction but is intended to be semi permanently attached upon completion - at present, my initial experiments with LED lighting haven’t convinced me this is the way to go and I may install a fluorescent tube if I don’t have any more luck, but we will see.

A nice cold day for Oly and myself in November was spent putting this together...

A bit more work and the front facia cut to shape - someone stole a chunk out of the front!!

Experiments with the lighting...

To provide a little vertical relief below rail level, I added a raised trackbed from ply, which has also helped strengthen the board a bit (too much 6mm ply remember!) and 5mm foamboard, then removed a small section of the solid top to create room for a minor stream to appear out of a culvert. This also means there is a minor but noticeable variation in height between the sidings at the front and rear, which makes a big difference in my opinion.

I’ve built the pointwork up from copperclad and code 75 BH Rail - I wanted to ensure the trackplan flowed through the layout and there were no lines running in straight lines parallel to the board edge. It’s intended that the left hand fiddle Yard will be cassettes whereas the right hand end will be a small loco release traverser.

Thats about as far as things have got so far, I'll soon be setting too on the topography with plenty of papier mache or filler, and have already started putting a few scenic features in place, such as this groove where a stream will descend a set of steps to reach the culvert that will pass under all lines.

I’ll leave it at that for now, in a future post I’ll cover the lines historical and geographical context in more detail (it's far too long to fit here!) as well as posting up plenty of progress updates.

I wonder if this will be the last cameo layout to appear out of the woodwork on here...!

Cheers

Chris

Hopefully you don’t mind me jumping straight in here, rather than heading through the new members section, but it made sense to keep everything in one place... so by way of an introduction, I’m Chris, half of the double act that put together the various bodgings that appear on otcm.wordpress.com

Despite never having previously posted on WT, I’ve been a lurker for a couple of years and wanted to share progress on my cameo competition entry through the forum, it feeling the best and easiest place to get feedback and take other people’s ideas on board to hopefully improve the final outcome. I planned on making the first post in November last year so am running a little late on the initial update - I’ve actually been trying to maximise time on the layout with some ‘little and often modelling’ rather than looking at forums hence not getting round to it...

I’ve spent the last 5 or so years in a bit of a layout drought, not having actually produced something single handedly since my mid teens - looking to move out my parents house and not knowing what space would be available for a layout essentially put layouts on the back burner although I spent plenty of time working on rolling stock. Myself and Oly then built Stoating Bank in a bit of a rush, and took it out to a few shows, but since then, despite now knowing what space I have and several false starts nothing has really appeared. The announcement of this competition, complete with deadline, seemed the ideal opportunity to get myself in gear and actually build something!

Now, onto the layout - from the outset I wanted the layout to be a little different, portraying a run down industrial scene in an early 1970’s winter. If possible the industrial railway would be supplemented by some BR action, but only if it didn’t result in things looking too cramped or too much compromise. This concept developed into an early plan for a small set of interchange sidings half way along an industrial line, with a couple of sidings serving various steel works buildings. A scale plan of this proved it fitted although somewhat cramped, into the 5ft space I had given myself to work in.

The only flaw with this was that upon measuring the car just prior to constructing the boards, it became obvious only a 4ft 6in board would fit, and as such the baseboard was built to this size - I certainly didn’t want to go down the van hire route for something no more than 10ft in total length, and this seemed to undermine the cameo concept somehow. Putting the plan onto the shortened board did not work at all, and it was back to the drawing board for a rethink.

Several ideas, geographical locations and plans later I finally found something I was happy with and seemed to offer sufficient operating potential. This is key to me getting any enjoyment out of operating, every movement must have a purpose and be carried out in a prototypical manner - you can’t run a ‘coal train’, but you can run 8M27, the 13.27 loaded coal from A to B.

The original plan had gone under the working title of ‘Bottom Works’, representing the lower half of a steelworks complex, and identifying the layout, hopefully, as being set in Yorkshire. I was keen to keep this name going but as the new plan no longer featured any works buildings (a cameo sized baseboard fills pretty quickly when steelworks buildings are on the agenda!) I added sidings to the name, what is modelled supposedly being the one time junction for a line serving a plant at a lower level.

I think the finished plan is a bit of a cross between a layout in its own right and a ‘bitsa’ - while it doesn’t try to portray a small part of a larger scene, it is totally reliant on the imaginary scene around it to work, so what am I modelling?

Towards the rear of the layout there is a freight only branch running from a set of exchange sidings to a small steel processing plant (the exact specification of this and the traffic it creates is still TBC...) This is maintained and operated by BR, with BSC movements having running powers. Mid way along the layout this connects with a BSC internal railway system serving a secondary entrance to a coking plant (assumed to have originally been part of the steel companies property portfolio) and there are a couple of loops for the interchange and holding of traffic. There are then a couple of sidings and a lifted line, formerly heading off to the previously mentioned Bottom Works (another area of the former steelworks). The whole concept is heavily inspired by the Stocksbridge Railway. Hopefully this overhead shot from before too much had happened gives an idea of the plan:

There is nothing special about the construction methods, the boards are a mixture of 6mm and 9mm ply - I’m certainly not a carpenter and as such the boards are a long way from perfect, but will hopefully do the job. (I didn’t want to end up restricted by the constraints of an off the shelf kit board, and was keen to follow the advice of Iain in the book with all the board components built in from the start.) In hindsight I wish there was a bit more 9mm in it for some added strength, but it is nice and lightweight... the lighting pelmet is removable at present to ease construction but is intended to be semi permanently attached upon completion - at present, my initial experiments with LED lighting haven’t convinced me this is the way to go and I may install a fluorescent tube if I don’t have any more luck, but we will see.

A nice cold day for Oly and myself in November was spent putting this together...

A bit more work and the front facia cut to shape - someone stole a chunk out of the front!!

Experiments with the lighting...

To provide a little vertical relief below rail level, I added a raised trackbed from ply, which has also helped strengthen the board a bit (too much 6mm ply remember!) and 5mm foamboard, then removed a small section of the solid top to create room for a minor stream to appear out of a culvert. This also means there is a minor but noticeable variation in height between the sidings at the front and rear, which makes a big difference in my opinion.

I’ve built the pointwork up from copperclad and code 75 BH Rail - I wanted to ensure the trackplan flowed through the layout and there were no lines running in straight lines parallel to the board edge. It’s intended that the left hand fiddle Yard will be cassettes whereas the right hand end will be a small loco release traverser.

Thats about as far as things have got so far, I'll soon be setting too on the topography with plenty of papier mache or filler, and have already started putting a few scenic features in place, such as this groove where a stream will descend a set of steps to reach the culvert that will pass under all lines.

I’ll leave it at that for now, in a future post I’ll cover the lines historical and geographical context in more detail (it's far too long to fit here!) as well as posting up plenty of progress updates.

I wonder if this will be the last cameo layout to appear out of the woodwork on here...!

Cheers

Chris