Greengiant

Western Thunderer

Track laying has started, first is board six.

The plates were cleaned up with a mop in a wizzy disk.

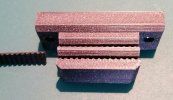

Clip positions were marked out, then they were soldered to the rail using a 150 watt iron to get enough heat in quickly. We made a simple jig by routing a groove in some plywood at the depth to hold the upturned rail and the clips in exactly the right plane.

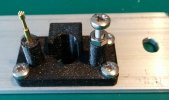

For rail end clips and some mid point clips we have some that have been drilled to accept small screws.

With end clips in place we used a rail bender to curve the rail until we got the flow we wanted.

Note that the plates are not always central on the sleeper width, this is not an error, that is how they appear on the actual railway.

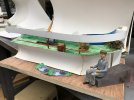

One board getting there, still to do is fitting of the pandrol clips, blackening of the rail and final fixing to the sleepers.

We got as far as board four with the track laying initial stage.

On the previous two boards the fishplates were soldered on using an RSU.

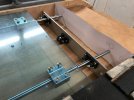

This photo shows that we cut the web and head of the rail to simulate rails joins.

Martin

The plates were cleaned up with a mop in a wizzy disk.

Clip positions were marked out, then they were soldered to the rail using a 150 watt iron to get enough heat in quickly. We made a simple jig by routing a groove in some plywood at the depth to hold the upturned rail and the clips in exactly the right plane.

For rail end clips and some mid point clips we have some that have been drilled to accept small screws.

With end clips in place we used a rail bender to curve the rail until we got the flow we wanted.

Note that the plates are not always central on the sleeper width, this is not an error, that is how they appear on the actual railway.

One board getting there, still to do is fitting of the pandrol clips, blackening of the rail and final fixing to the sleepers.

We got as far as board four with the track laying initial stage.

On the previous two boards the fishplates were soldered on using an RSU.

This photo shows that we cut the web and head of the rail to simulate rails joins.

Martin