OzzyO

Western Thunderer

Hello all,

I picked up a O gauge Heljan class 40 for a very good price of £220 +£16 for P & P. with no motors. But when I opened it up it also had no gears, pick ups, lights, etc. But it still looked like a bargain, some of the bits I'll make myself, some of the bits are not needed. Onto the photos.

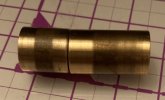

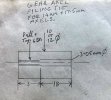

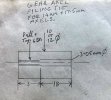

The photo of the filling jig, this will also be used for setting the gears at the correct distance from the end of the gear shaft. I'm quit happy to mix imperial and metric in my drawings.

This photo is of my first class 40 that is complete. This photo shows all of the gears in place, along with the pick ups (you will see that one of them has become displaced from the top L/H driving wheel. I'm also going to have to fix some of the sand pipes into the correct place

Time to put our tea on,

ATB

OzzyO.

I picked up a O gauge Heljan class 40 for a very good price of £220 +£16 for P & P. with no motors. But when I opened it up it also had no gears, pick ups, lights, etc. But it still looked like a bargain, some of the bits I'll make myself, some of the bits are not needed. Onto the photos.

The photo of the filling jig, this will also be used for setting the gears at the correct distance from the end of the gear shaft. I'm quit happy to mix imperial and metric in my drawings.

This photo is of my first class 40 that is complete. This photo shows all of the gears in place, along with the pick ups (you will see that one of them has become displaced from the top L/H driving wheel. I'm also going to have to fix some of the sand pipes into the correct place

Time to put our tea on,

ATB

OzzyO.

. Well it will go into the tool box for use at a latter date. Now to wait for it to turn up so I can make the filling jig.

. Well it will go into the tool box for use at a latter date. Now to wait for it to turn up so I can make the filling jig.

plus £8.00 import charges

plus £8.00 import charges

)

)